Dishwasher

A dishwasher and washing pump technology, applied in the application of dishwasher, washing machine/washing machine for tableware, parts of washing machine/rinsing washing machine for tableware, etc., can solve the problem of inability to clean, increase water consumption, consumption Water volume increase and other problems, to achieve the effect of good self-cleaning ability, simple and reliable structure, and improved cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

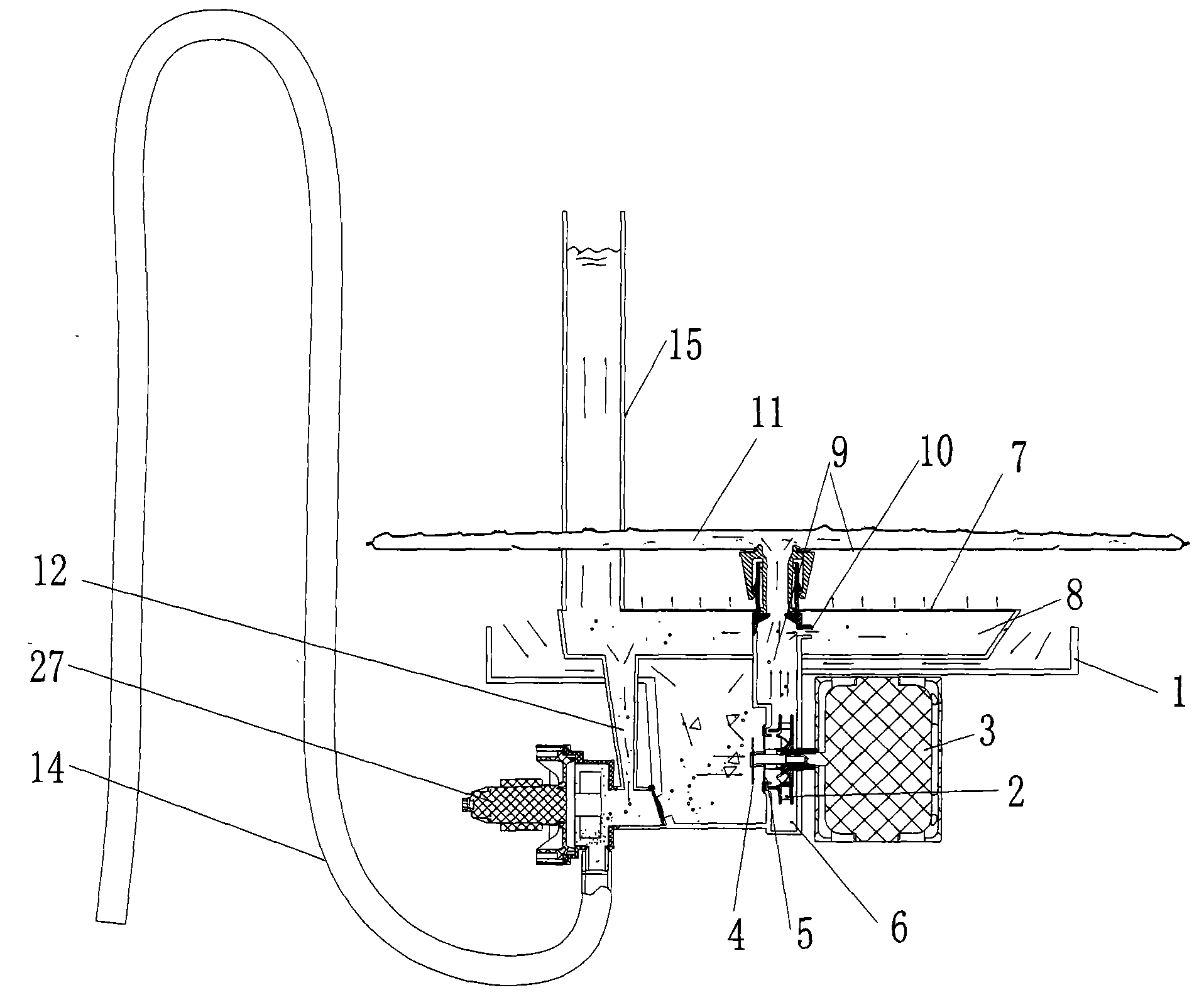

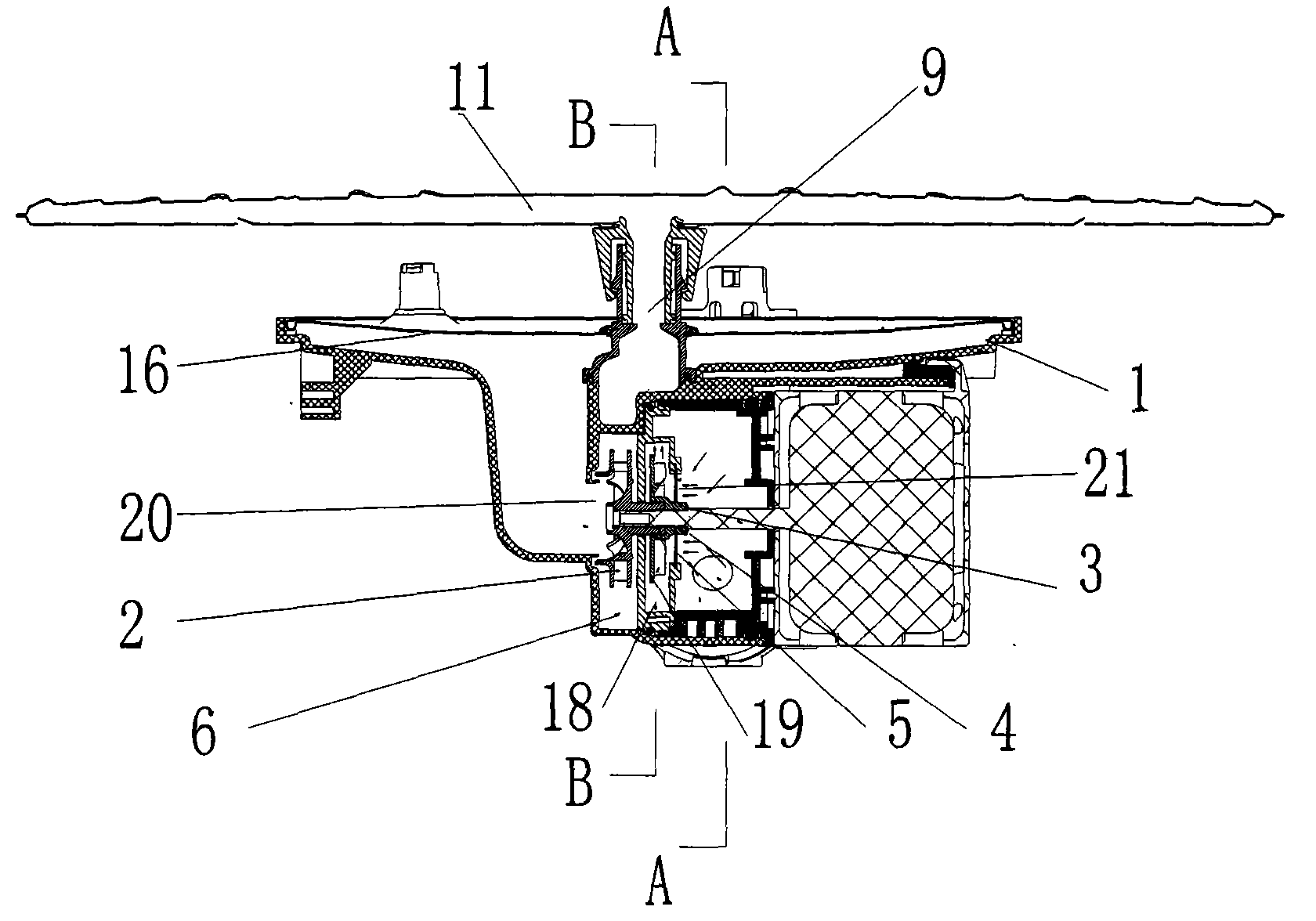

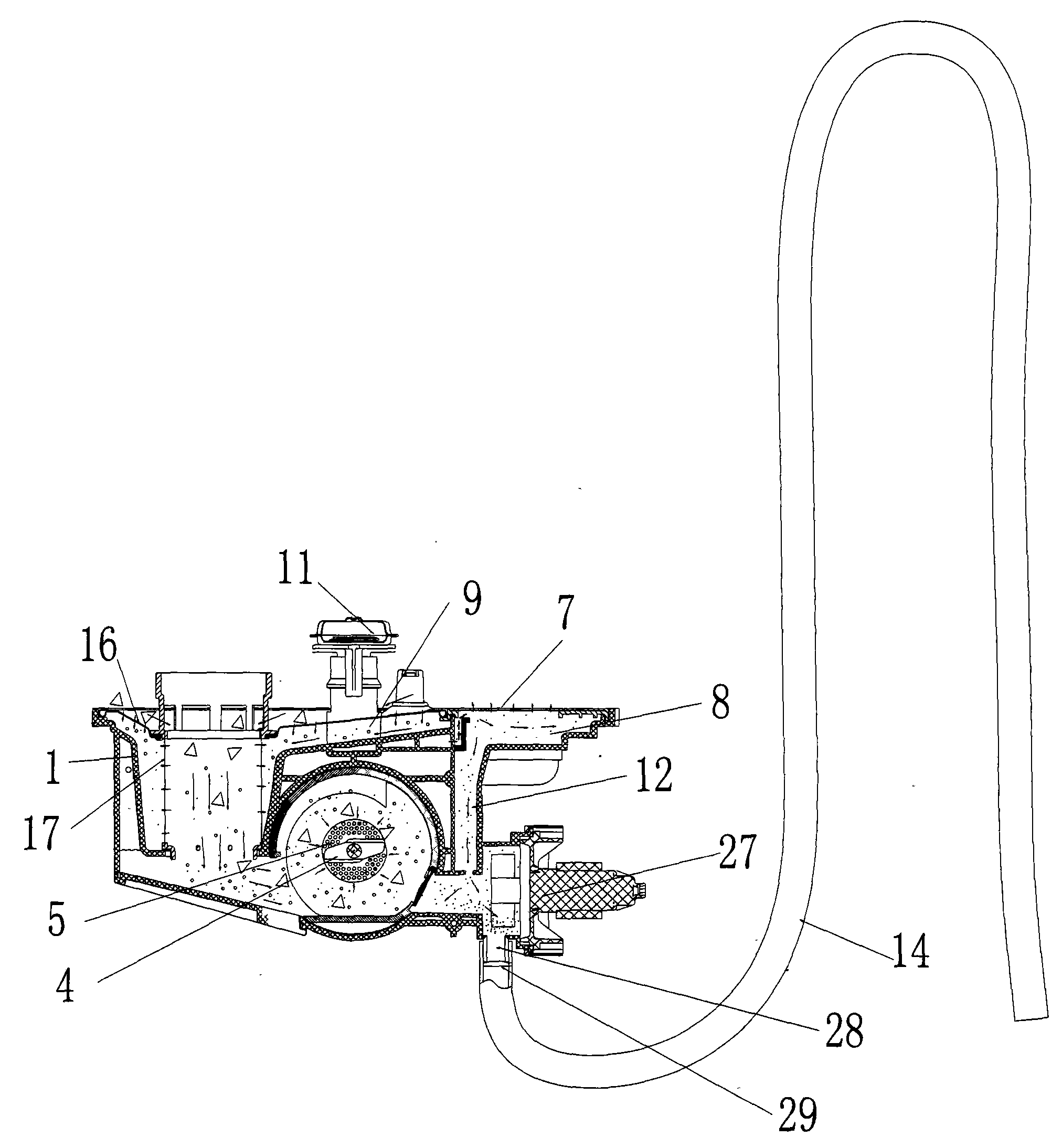

[0023] Such as Figures 2 to 5 Shown is a schematic structural diagram of the washing system and pressure relief system of the dishwasher disclosed in the embodiment of the present invention. as attached figure 2 As shown, the upper part of the water cup 1 at the bottom of the dishwasher liner is provided with a planar filter 16, which is a concave spherical surface, and the planar filter is provided with a columnar filter 17, columnar The upper end face of filter 17 is higher than the upper surface of planar filter 16, and the lower end of columnar filter 17 is connected with the opening at the bottom of water cup 1, and the opening at the bottom of water cup communicates with the water inlet of circulating pump chamber 18; Washing pump chamber 6 The water inlet 20 communicates with the space enclosed between the planar filter 16, the columnar filter 17 and the water cup 1, and the water outlet is connected with the shower device (as the spray arm 11) of the washing system....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com