Discharge gate mechanism

A door mechanism and material cutting technology, applied in mechanical equipment, engine components, lift valves, etc., can solve the problems of heavy ball valve or butterfly valve, transportation, production and storage, waste of production materials, etc., to achieve good sealing, keep materials characteristics, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

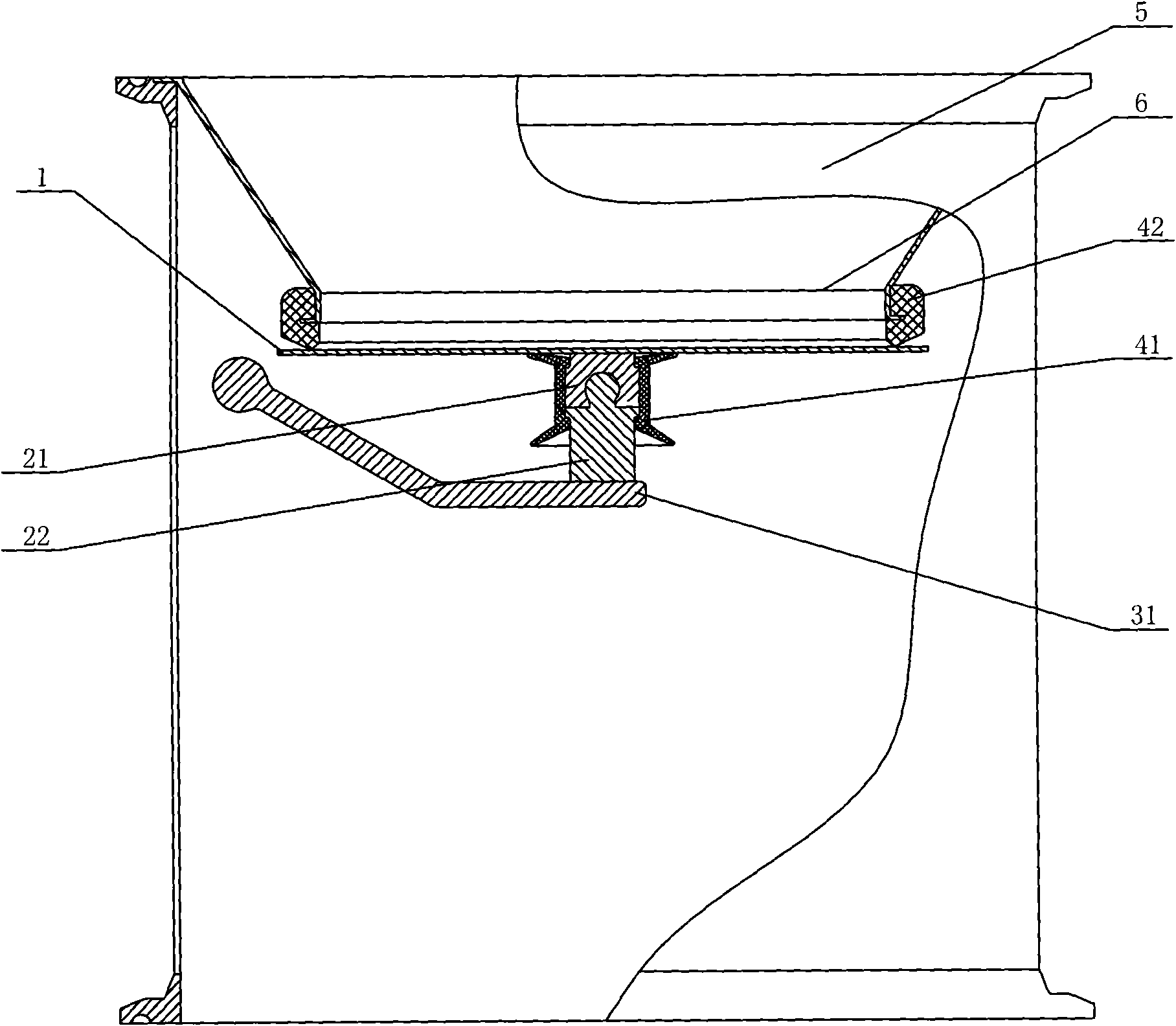

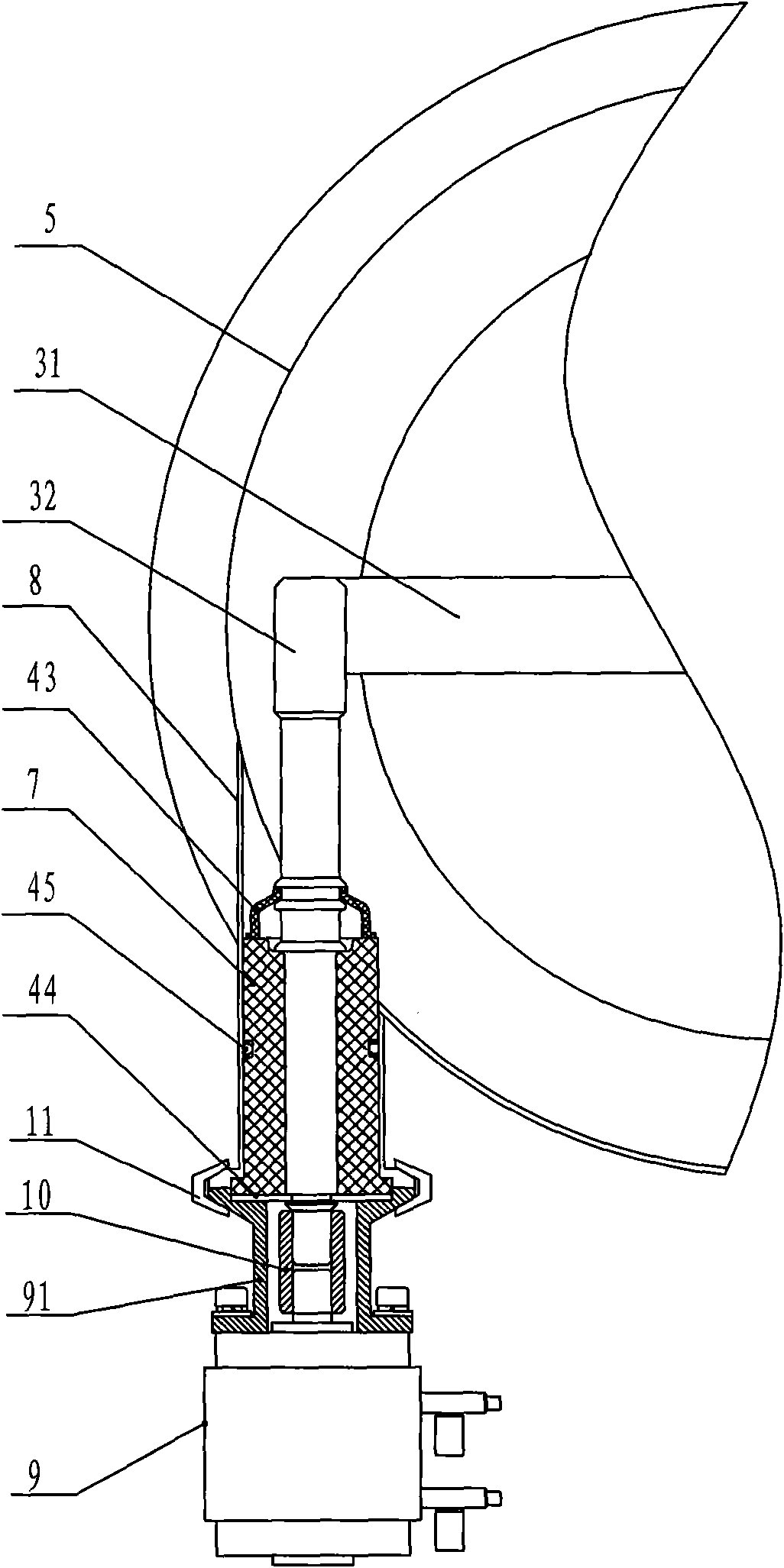

[0027] A kind of unloading gate mechanism of the present invention, as figure 1 As shown, the unloading door 1 is a flat plate, which touches the unloading hopper opening 6 inside the unloading cabin 5, and is connected with the L-shaped crank arm 31 through the pin seat 21 and the latch pin 22 of the coupling, wherein the pin seat 21 is fixed. At the center of the lower part of the unloading door 1, the latch 22 is fixed at the end of the first arm 31 of the L-shaped crank arm; the joint is provided with a sealing rubber sleeve that seals the connection between the unloading door 1, the pin seat 21 and the latch 22 41. The sealing rubber sleeve 41 can not only prevent the material from being polluted and denatured, but also prevent the material from entering the connection to affect the rotation of the unloading door 1, and can also prevent the bolt 22 from being separated from the pin seat 21 and cause the unloading door 1 to fall off.

[0028] The contact surface between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com