Polylactic acid forming body and making method thereof

A manufacturing method, polylactic acid technology, applied in the direction of coating, etc., can solve problems such as practical technical limitations, and achieve the effect of improving heat resistance and mechanical properties

Inactive Publication Date: 2009-10-14

鸿福鑫有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] The present invention is to solve the shortcomings of commonly used polylactic acid in terms of insufficient heat resistance and mechanical properties, and the problems of limited practical technology. On the one hand, it aims to increase the heat-resistant temperature and improve the mechanical properties. On the other hand, it is to apply crystalline polylactic acid to injection molding processing to manufacture products in various industrial fields, in order to achieve the basic functions that should be possessed, and to make it both industrially applicable to the actual development and competition requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

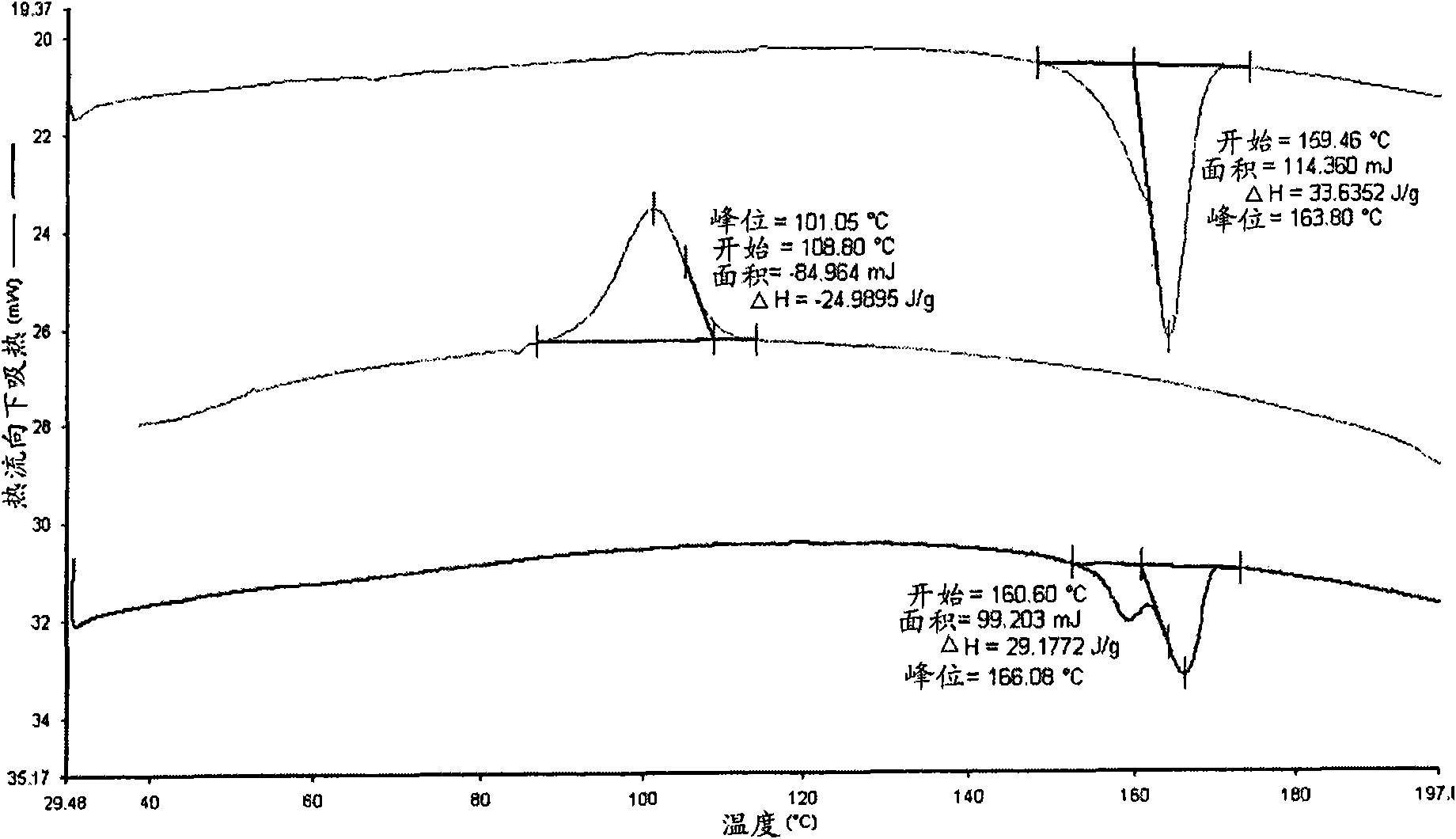

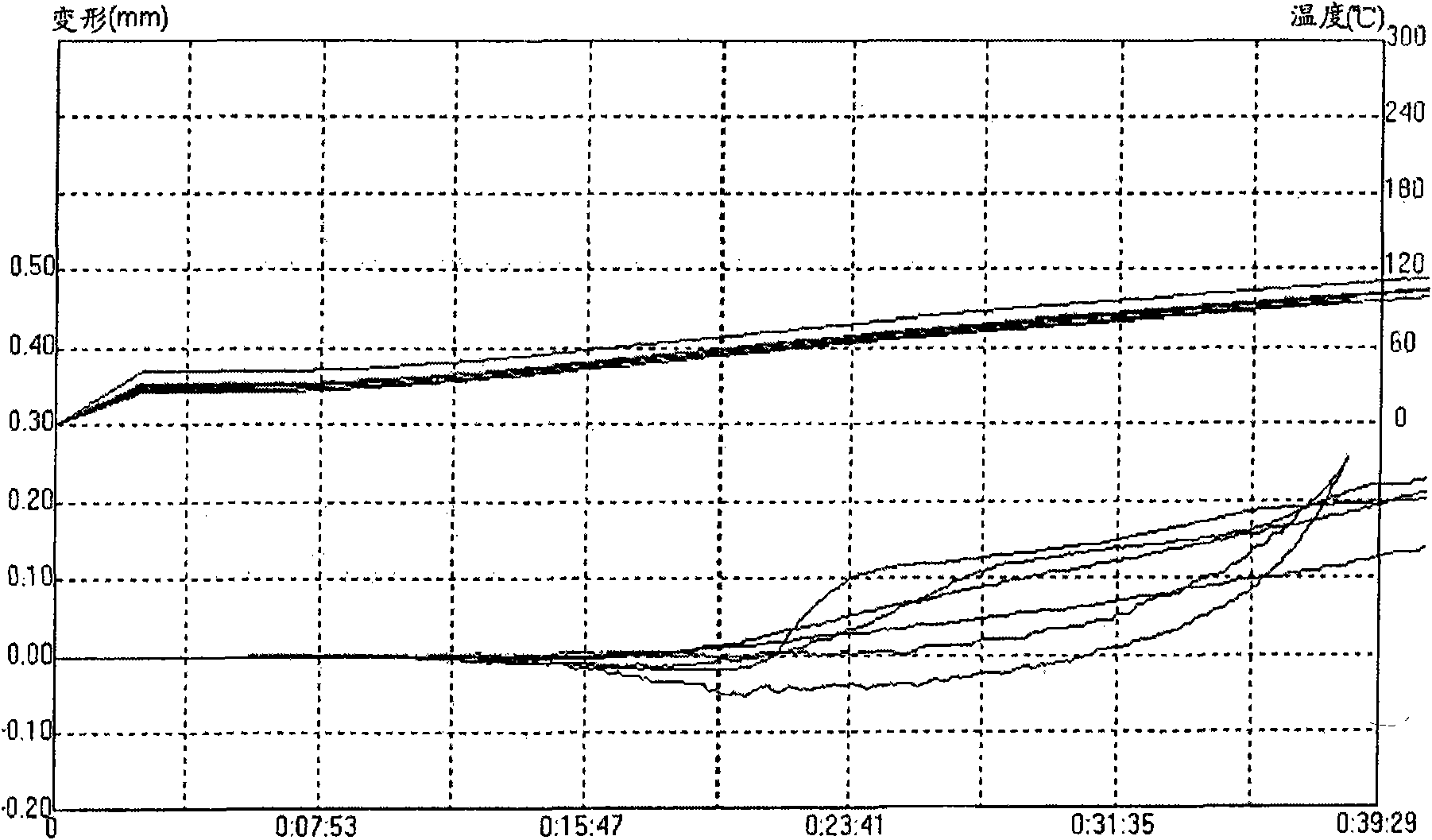

[0040] Example 1: The mold surface temperature is 90° C., and the molding time is 60 seconds.

Embodiment 2

[0041] Example 2: The mold surface temperature is 100° C., and the molding time is 60 seconds.

Embodiment 3

[0042] Example 3: The mold surface temperature is 110° C., and the molding time is 60 seconds.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a making method of polylactic acid forming body, which enables polylactic acid to be continuously ejected to form the polylactic acid forming body with heat resistance. The making method is characterized in that at the time of the ejection of polylactic acid, the thermoform of the polylactic acid is performed in a metal die, the polylactic acid in the metal die is crystallized at constant temperature so as to achieve the effects of crystallization and heat resistance, and a finished product formed by die sinking ejection keeps good shape and does not deform. The making method can adopt a continuous method to produce polylactic acid products with heat resistance, all ejection products using the polylactic acid as materials can be made by the forming and processing process, and the polylactic acid after forming and processing has heat resistance and favorable mechanical characteristics.

Description

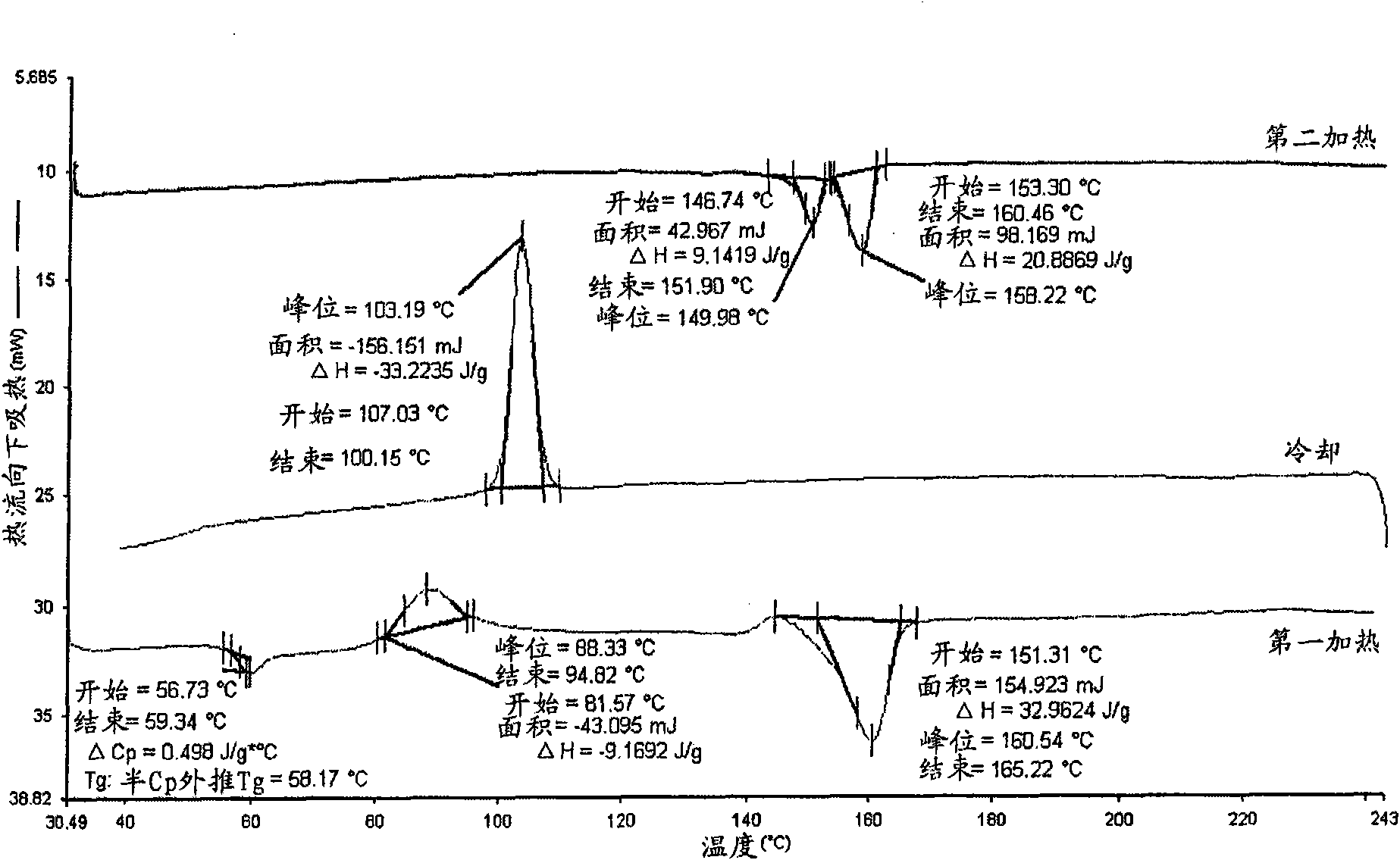

technical field [0001] The invention relates to a manufacturing method for continuous injection molding of polylactic acid with heat resistance, in particular to a method of crystallizing polylactic acid at a constant temperature in a metal mold and forming a polylactic acid molded body to achieve the effect of crystallization and heat resistance . Background technique [0002] According to the commonly used polylactic acid (PLA) through injection molding method, the heat distortion temperature of polylactic acid products is only about 58°C, which is far lower than the commonly used plastics PS and PP. [0003] Although polylactic acid is a crystalline polymer, it hardly crystallizes during the actual molding process. The heat resistance of polylactic acid is poor, which is caused by the very slow crystallization rate of polylactic acid; It is related to the secondary nucleation rate. There is only one methyl carbon atom between the ester groups of polylactic acid, and the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C45/00B29C71/02B29C45/78B29C45/73B29K67/00

Inventor 王钰琴陈修谦

Owner 鸿福鑫有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com