Method for controlling online calibration of pulling-straightening roller gap under light pressure of bloom caster

A control method and soft reduction technology, which is applied in the field of bloom continuous casting soft reduction technology, can solve problems such as low efficiency and unstable quality of blooms, and achieve the goal of reducing center segregation, eliminating center shrinkage cavity and center porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

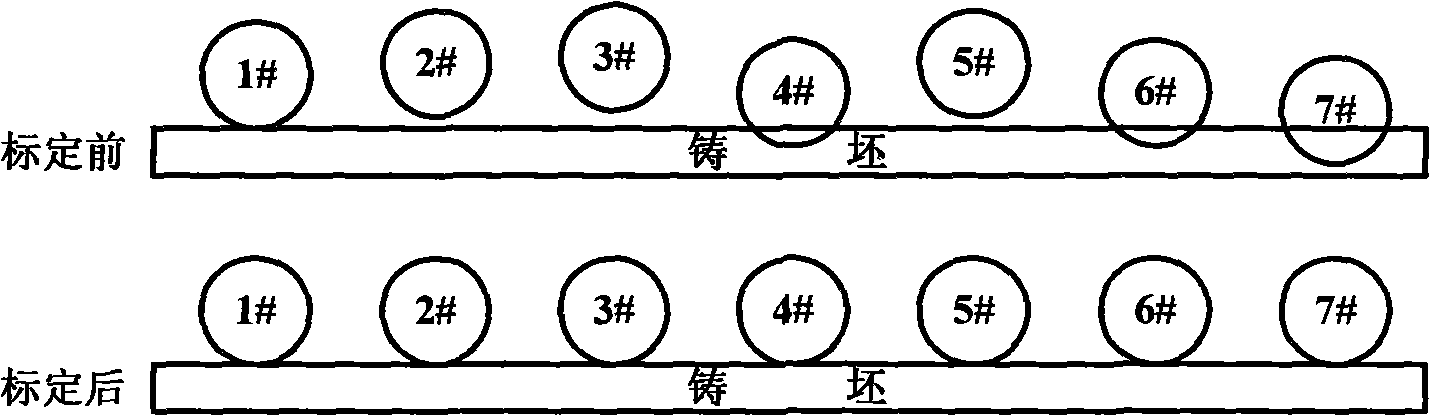

[0039] (1) Casting machine equipment parameters: full arc bloom continuous casting machine, radius 12m, straightening section and horizontal section casting roller diameter of 450mm, casting machine metallurgical length 33.149m (liquid level to flame cutting machine origin) . The distribution of tension leveling rolls is shown in Table 1.

[0040]Table 1 The position of each roller of the tension leveling machine

[0041]

[0042] (2) The billet size is 280mm×325mm, the steel type is GCr15, and the total reduction is 10mm. The steel composition, casting temperature and casting speed are shown in Table 2.

[0043] Table 2 Steel composition, casting temperature and casting speed

[0044]

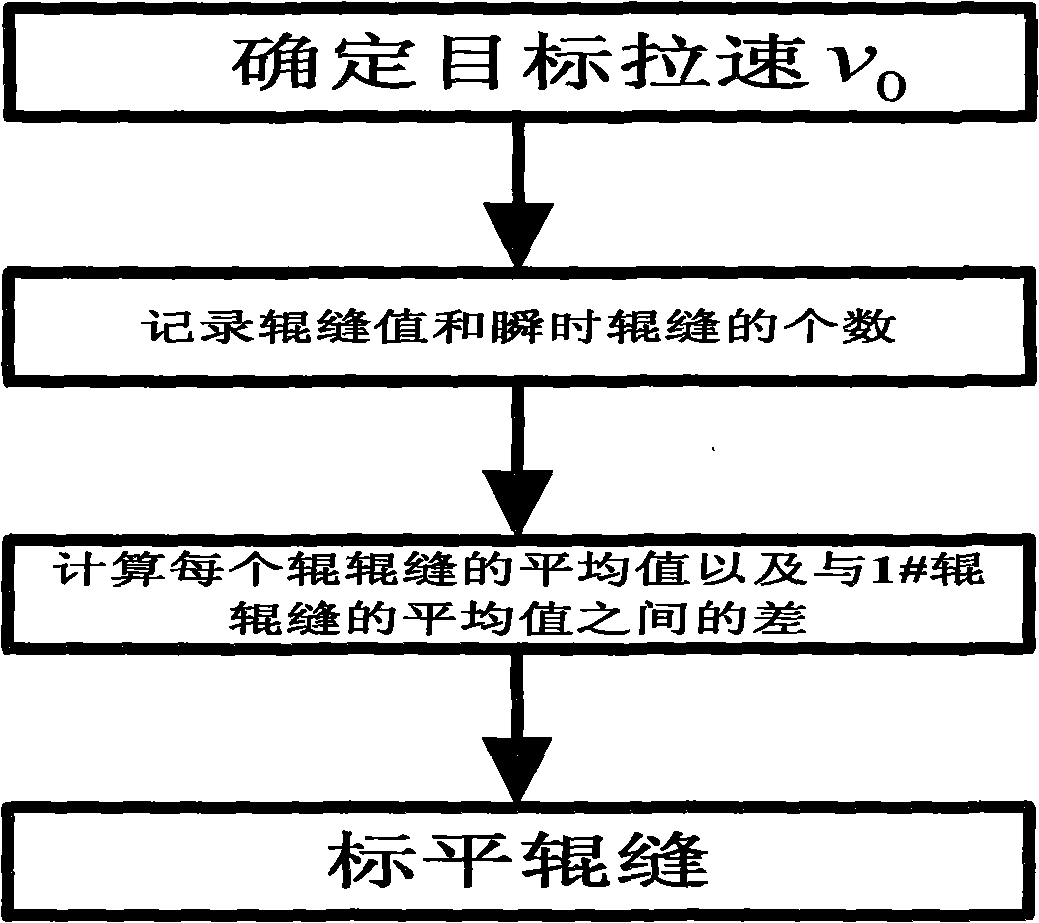

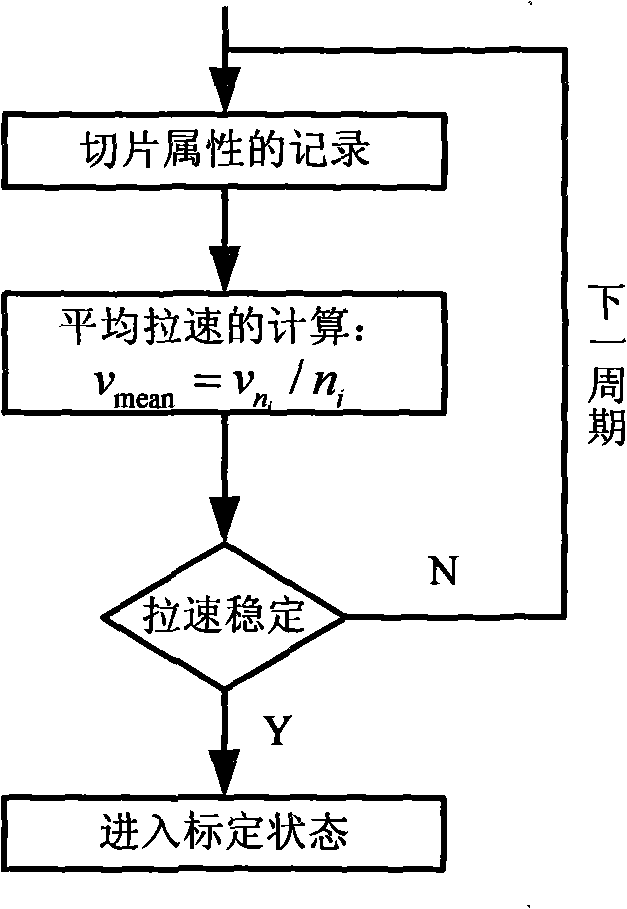

[0045] (3) When casting bearing steel, when the casting speed is 0.78m / min, the end point of solidification is 23.4m, so the set casting speed under light reduction is 0.78m / min, and the target casting speed for determining the roll gap calibration is also 0.78m / min.

[0046] (4) The...

Embodiment ( 2

[0052] (1) The parameters of the casting machine equipment are as in Example (1)

[0053] (2) The billet size is 280mm×325mm, the steel type is SWRH82B, and the total reduction is 9mm. The steel composition, casting temperature and casting speed are shown in Table 4.

[0054] Table 4 steel composition, casting temperature and casting speed

[0055]

[0056] (3) When casting SWRH82B, when the casting speed is 0.80m / min, the end point of solidification is 23.3m, so the set casting speed under light reduction is 0.80m / min, and the target casting speed for roll gap calibration is also 0.80 m / min.

[0057] (4) The size and set reduction of the cold slab are shown in Table 5.

[0058] Table 5 Comparison table of furnace number, cold billet size and set reduction

[0059]

[0060] Table 5 is the experimental data during the hot test of SWRS82B, and the detection method is the same as that of bearing steel GCr15. It can be seen that after online calibration of SWRH82B, the s...

Embodiment ( 3

[0062] (1) The parameters of the casting machine equipment are as in Example (1)

[0063] (2) The billet size is 280mm×325mm, the steel type is SWRH72A, and the total reduction is 9mm. The steel composition, casting temperature and casting speed are shown in Table 6.

[0064] Table 6 Steel composition, casting temperature and casting speed

[0065]

[0066] (3) When casting SWRH72A, when the casting speed is 0.75m / min, the end point of solidification is 22.0m, so the set casting speed under light reduction is 0.75m / min, and the target casting speed for roll gap calibration is also 0.75 m / min.

[0067] (4) The size of the cold slab and the set reduction are shown in Table 7.

[0068] Table 7 Comparison table of heat number, cold billet size and set reduction

[0069]

[0070] Table 7 is the experimental data during the hot test of SWRS72A, and the detection method is the same as that of bearing steel GCr15. It can be seen that after online calibration is adopted, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com