Electric control switch type holographic polymer dispersed liquid crystal diffractive beam splitter

A diffractive beam splitter and electronically controlled switch technology, applied in the optical field, can solve the problems of inability to meet the requirements of miniaturization, integration and high efficiency of optical systems, easy damage to coatings, and high energy loss, etc., and achieves good polarization and application range. The effect of wide and electronic control performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

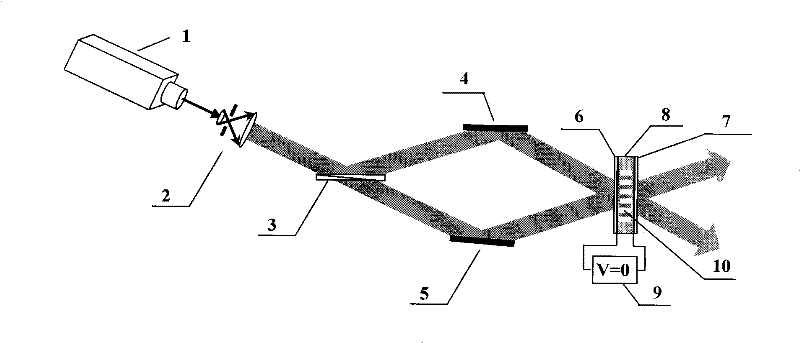

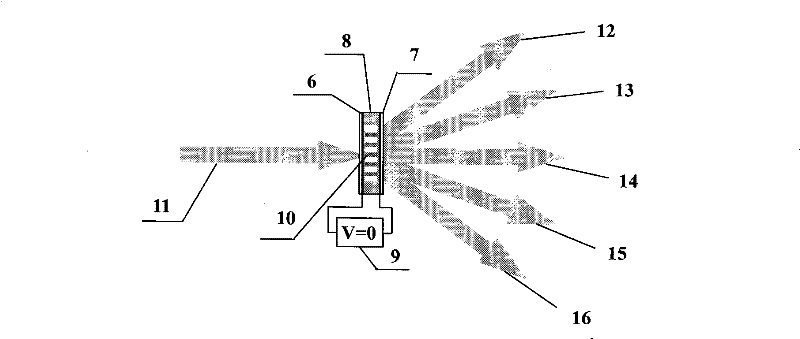

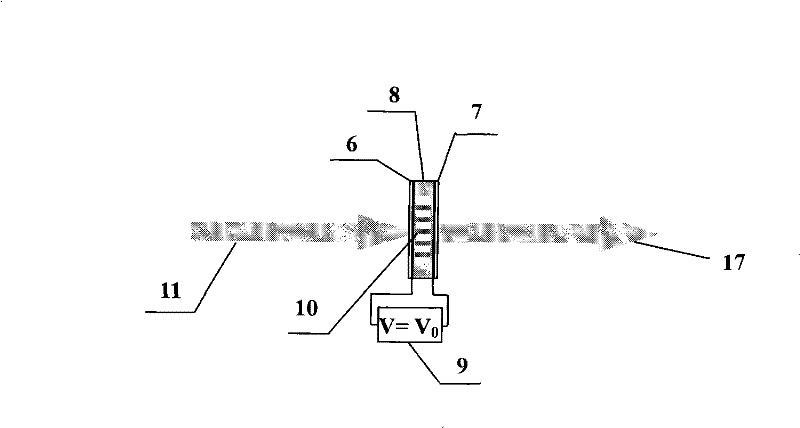

[0015] The raw material components of the polymer liquid crystal film are: the monomer is dimethylolpropane triacrylate monomer or trimethylolpropane triacrylate monomer, the crosslinking agent is N-vinylpyrrolidone, and the light The initiator is N-phenylglycine, the photosensitizer is sodium tetrachlorotetraiodofluorescein, the nematic liquid crystal is n-pentylcyanobiphenyl liquid crystal, and the mass ratio of the five components is: 35.4:13:1:0.6 : 50. The thickness of the polymer liquid crystal film prepared between two ITO glass substrates is 20-40 microns. Such as figure 1 , the laser light output by the laser 1 is expanded by the spatial light filter 2, divided into two beams by the beam splitter 3, and then reflected by the reflectors 4 and 5 so that the two beams of light are at a small angle (0.5 ~5 degrees) coupling to generate a Raman-Nath type grating 10, wherein the exposure time is 5-6 seconds. No voltage is applied to the ITO glass substrates 6 and 7 durin...

Embodiment 2

[0017] The operating steps are the same as in Example 1. The monomer is tetramethylolpropane triacrylate, the crosslinking agent is hexamethylolmelamine, the photoinitiator is azobenzene, etc., the photosensitizer is methyl red, and the nematic liquid crystal is nitrile diphenyl or In the terphenyl mixed liquid crystal, the mass ratio of the five components is: 40.3:10:1.5:0.7:47.5. The thickness of the polymer liquid crystal film is 40-60 microns. During exposure, the angle between the two laser beams is 5-10 degrees, and the exposure time is 6-8 seconds. The switch state is the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com