Thermal power plant combined ventilation direct air cooling system

A technology for thermal power plants and air cooling systems, used in steam/steam condensers, lighting and heating equipment, tubular elements, etc. problems, to achieve the effect of optimizing the technical approach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

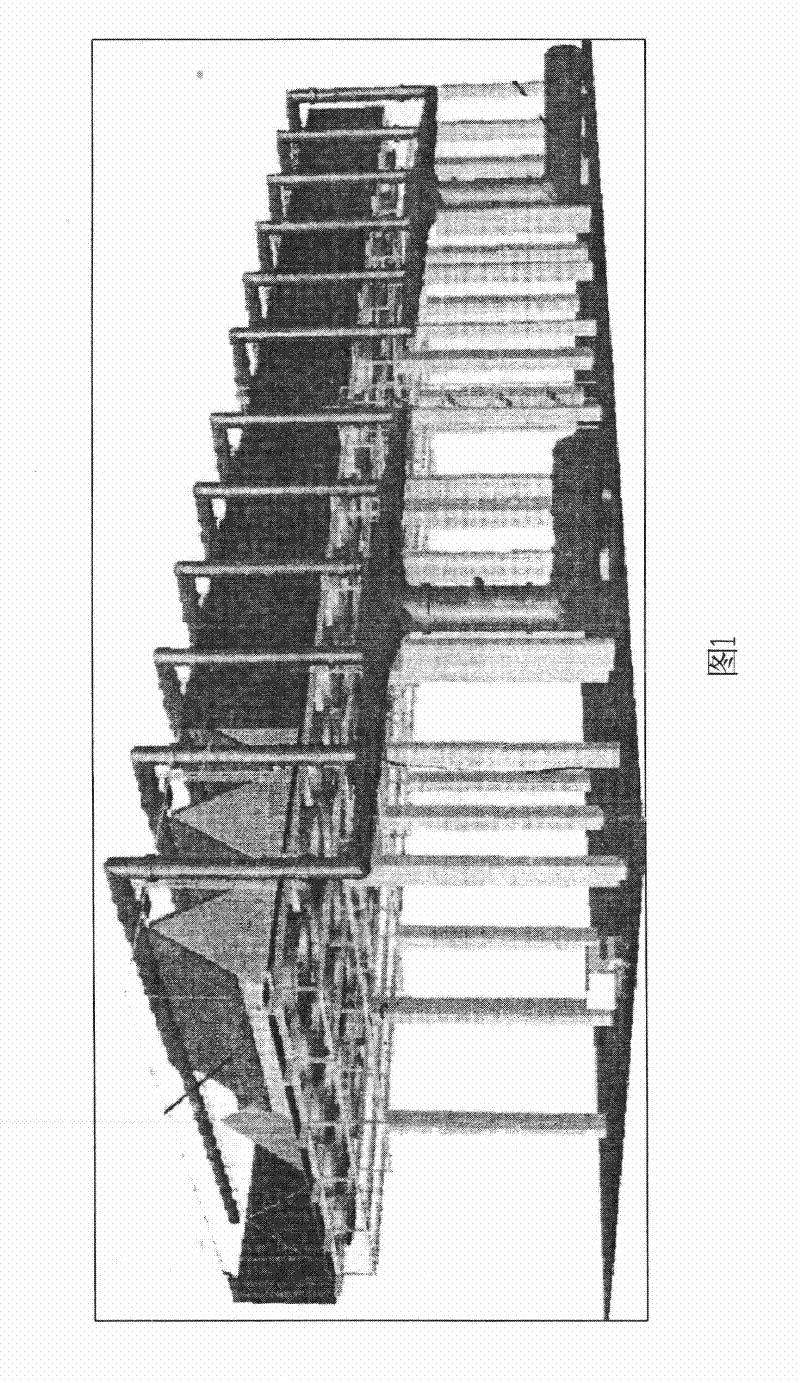

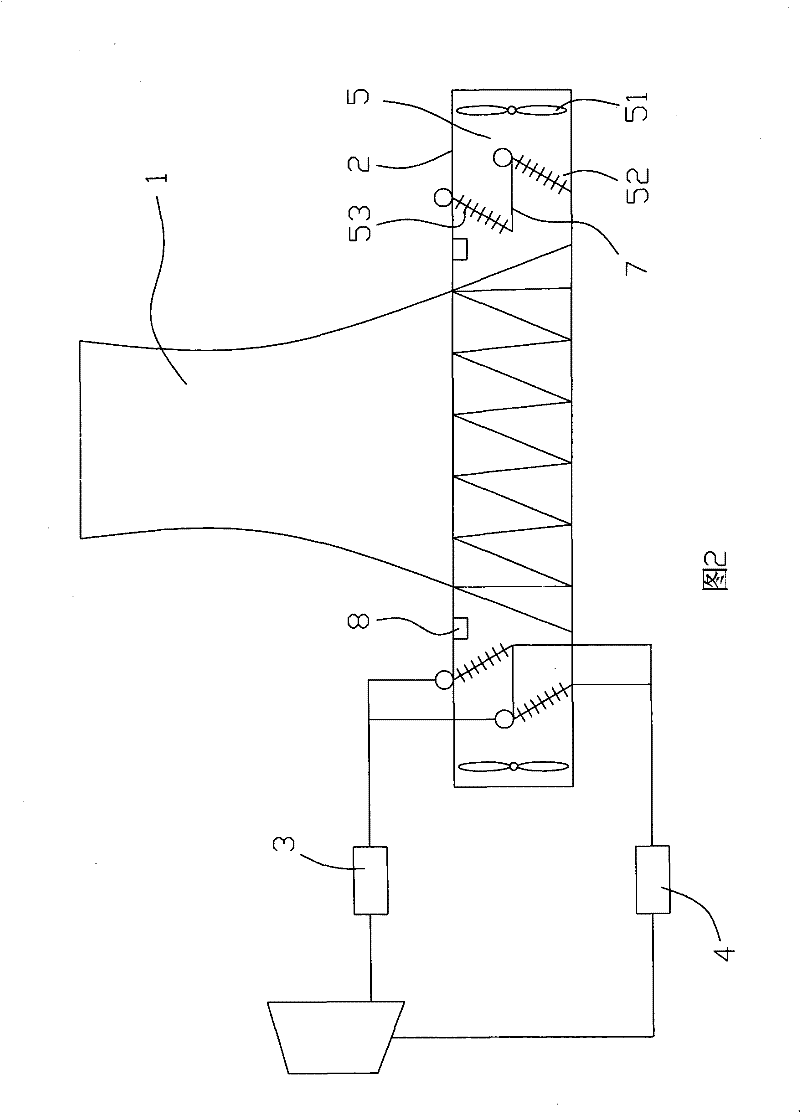

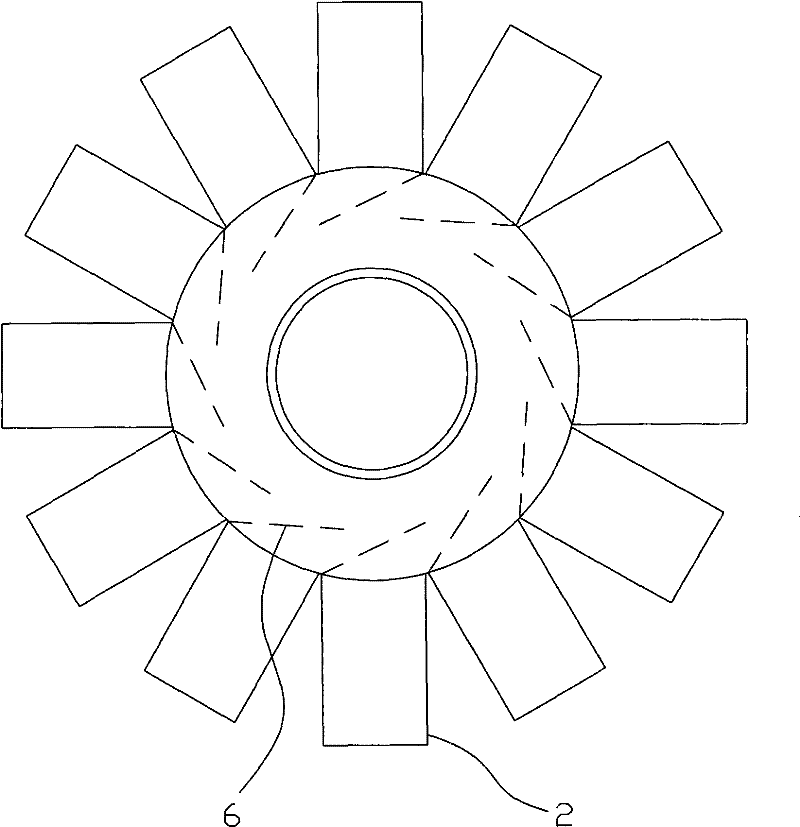

[0027] Such as figure 2 As shown, the combined ventilation direct air cooling system of the thermal power plant of the present invention comprises a hyperbolic air cooling tower 1, the outside of the bottom of the air cooling tower 1 is densely covered with several air inlet passages 2 along its circumference, and the air inlet passages 2 are cylindrical structures. The air passage 2 can be made of a square pipe, the outer end of the air inlet passage 2 is open, the inner end of the air inlet passage 2 communicates with the inside of the air cooling tower 1, and each air inlet passage 2 is provided with an air condenser unit 5 . The air condenser unit 5 includes an axial fan 51 and a heat dissipation fin tube bundle 52 , and the axial flow fan 51 and the heat dissipation fin tube bundle 52 are arranged along the axis of the air inlet channel 2 . A cooling fin cleaning device 8 is also arranged in the air inlet channel 2 .

[0028] The axial flow fan 51 in the air condenser u...

Embodiment 2

[0039] Such as Figure 5 As shown, in order to meet the working requirements of different climates and different regions, the outside of the bottom of the air cooling tower 1 of the present invention can be provided with multiple layers of the air inlet channel along the height direction. In this embodiment, upper and lower layers of air inlet channel 9 and air inlet channel 10 are arranged. The structures of the air inlet channel 9 and the air inlet channel 10 , internally connected devices, externally connected devices, etc. are all in common with those in the first embodiment. In order to form a helical discharge airflow in the air cooling tower 1, two sets of corresponding structures have been designed in the present embodiment: 1) as Image 6 As shown, in the cooling tower 1, a deflector with an included angle with the radial line of the air cooling tower 1 is provided, and each air inlet channel is correspondingly provided with a deflector; 2) as Figure 7 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com