Rotary cylinder using planar end oil film for sealing hydraulic slipring

A hydraulic slip ring and oil film sealing technology, applied in the field of CNC machine tools, can solve the problem of low speed and achieve the effects of small energy loss, simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

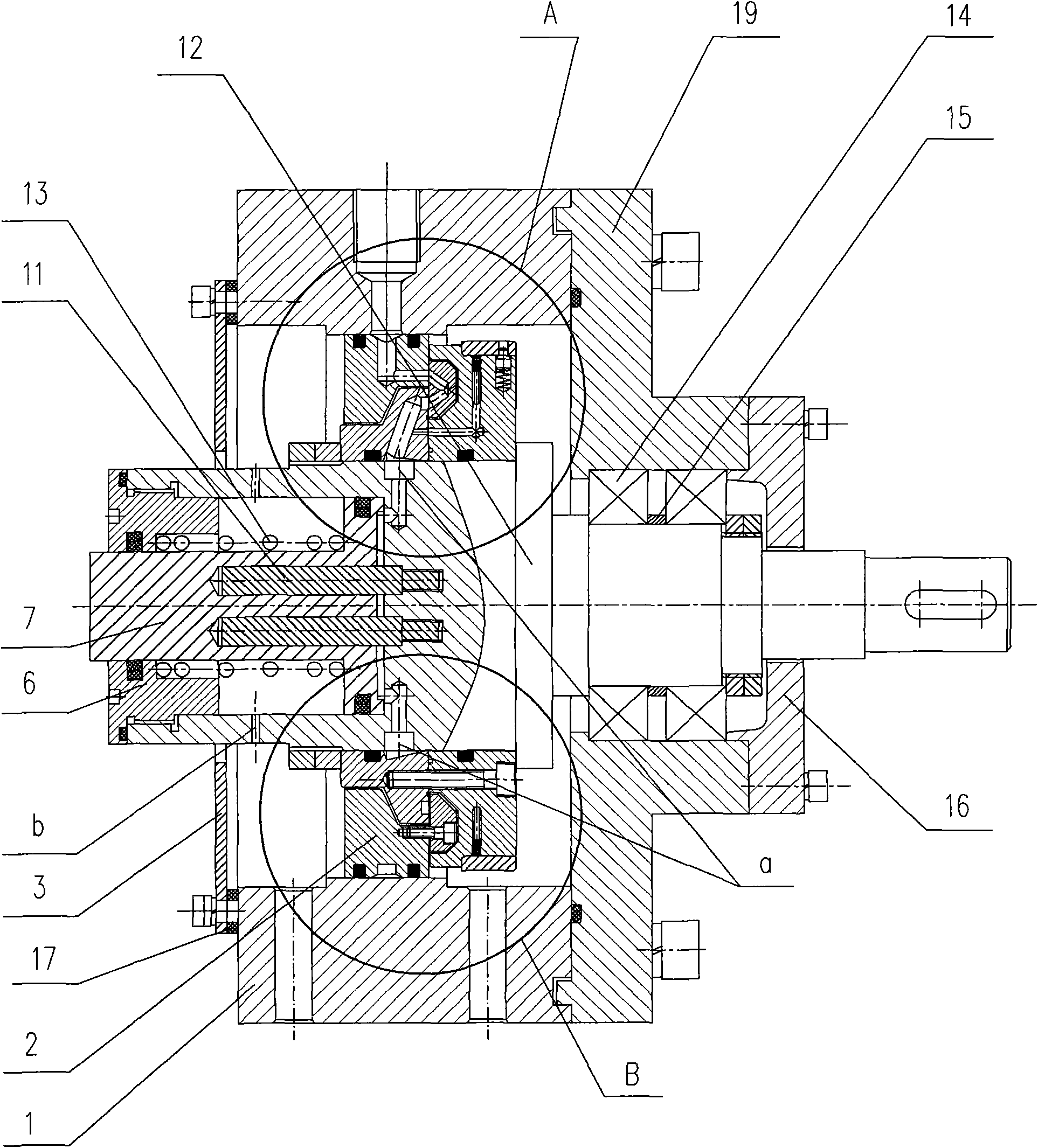

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment is composed of a hydraulic slip ring 2, a cylinder head 6, a piston 7, a drive pin 11, a shaft 12, a spring 13, a bearing 14 and a housing. One end of the shaft 12 is connected to the motor through a coupling, and the shaft The end of the other end of 12 has a cylinder body, and the end face in the cylinder body of the shaft 12 is provided with a hole, and one end of the drive pin 11 and the hole on the end face of the cylinder body of the shaft 12 adopt threaded cooperation, and the other end of the drive pin 11 The hole on the end face of the head of the piston 7 adopts clearance fit. The cylinder head 6 is set on the piston rod of the piston 7 and seals the cylinder body of the shaft 12. The spring 13 is set on the piston rod of the piston 7 and supported on the cylinder head 6 and the piston. 7 Between the heads, the shaft 12 is fixedly connected to the casing through the b...

specific Embodiment approach 2

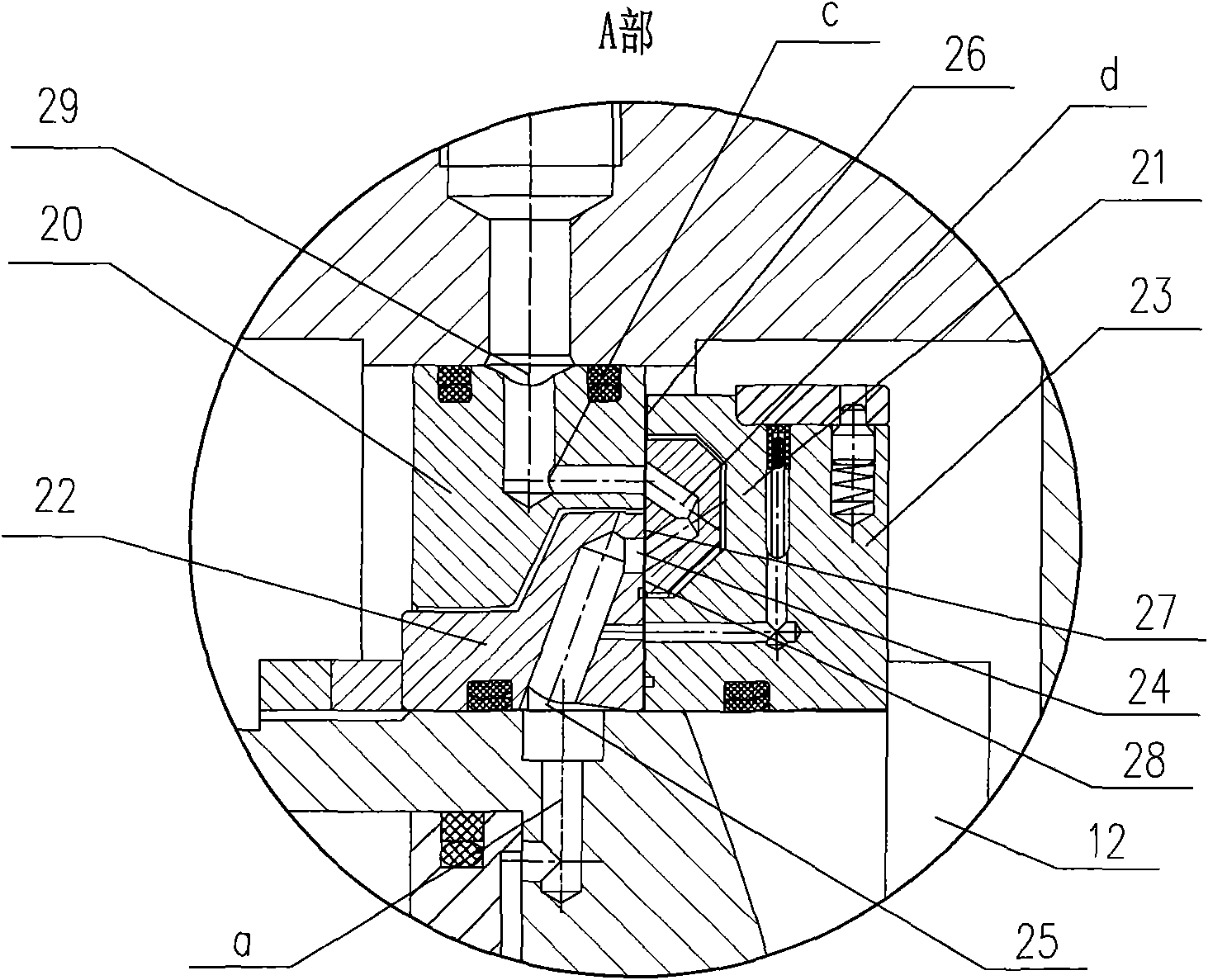

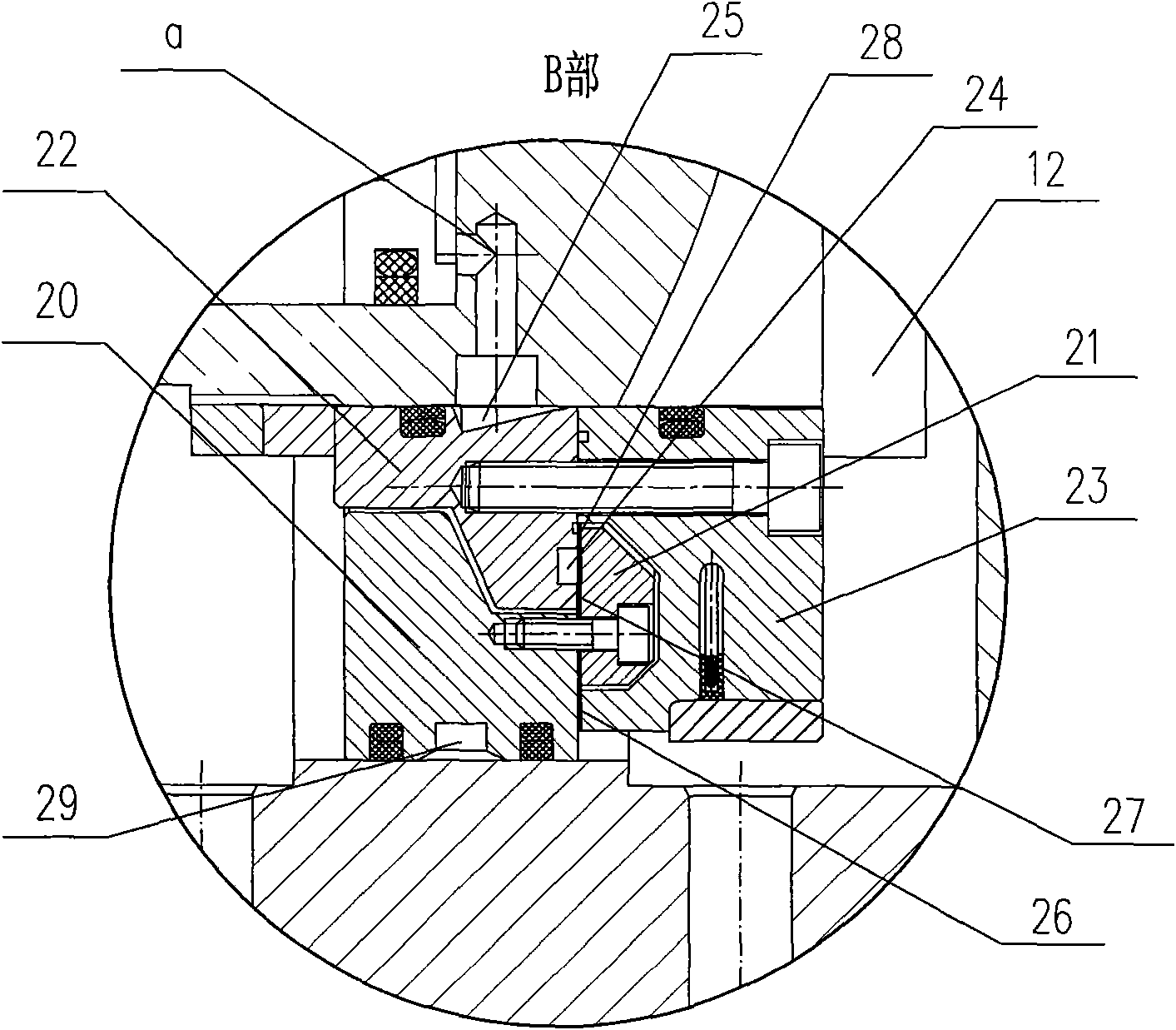

[0013] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the hydraulic slip ring 2 is composed of a first component 20, a second component 21, a third component 22 and a fourth component 23; the first component 20 and the second component 21 are fixedly connected together, the third part 22 and the fourth part 23 are fixedly connected together, the second part 21 is embedded in the fourth part 23, an L-shaped through hole c is opened on the first part 20, the said first part There is an oil inlet ring groove 29 on the surface connecting the first part 20 and the housing, a V-shaped through hole d is opened on the second part 21, and a ring-shaped through hole d is opened on the connecting surface of the third part 22 and the second part 21. Groove 24, a tapered annular groove 25 is formed on the surface where the third part 22 is connected with the shaft 12,...

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the gap between the first part 20 and the fourth part 23 is the first gap 26, and the annular groove between the second part 21 and the third part 22 The slits on both sides of 24 are respectively the second slit 27 and the third slit 28; the first slit 26, the second slit 27 and the third slit 28 are on the same plane, and the slit value of the three slits is h; The pressure oil between the slit 26, the second slit 27 and the third slit 28, and the pressure oil in the annular groove 24 respectively establish a pressure plane and a pressure area, thereby constituting a static pressure adjustment mechanism; the pressure oil passes through the through hole Transmission to the cylinder of the shaft 12; the first gap 26, the second gap 27 and the third gap 28 constitute three variable restrictors, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com