Honeycomb composite clean wall plate

A wall panel, clean technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of heavy weight of building panels, and achieve the effects of high flatness, not easy to spread, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

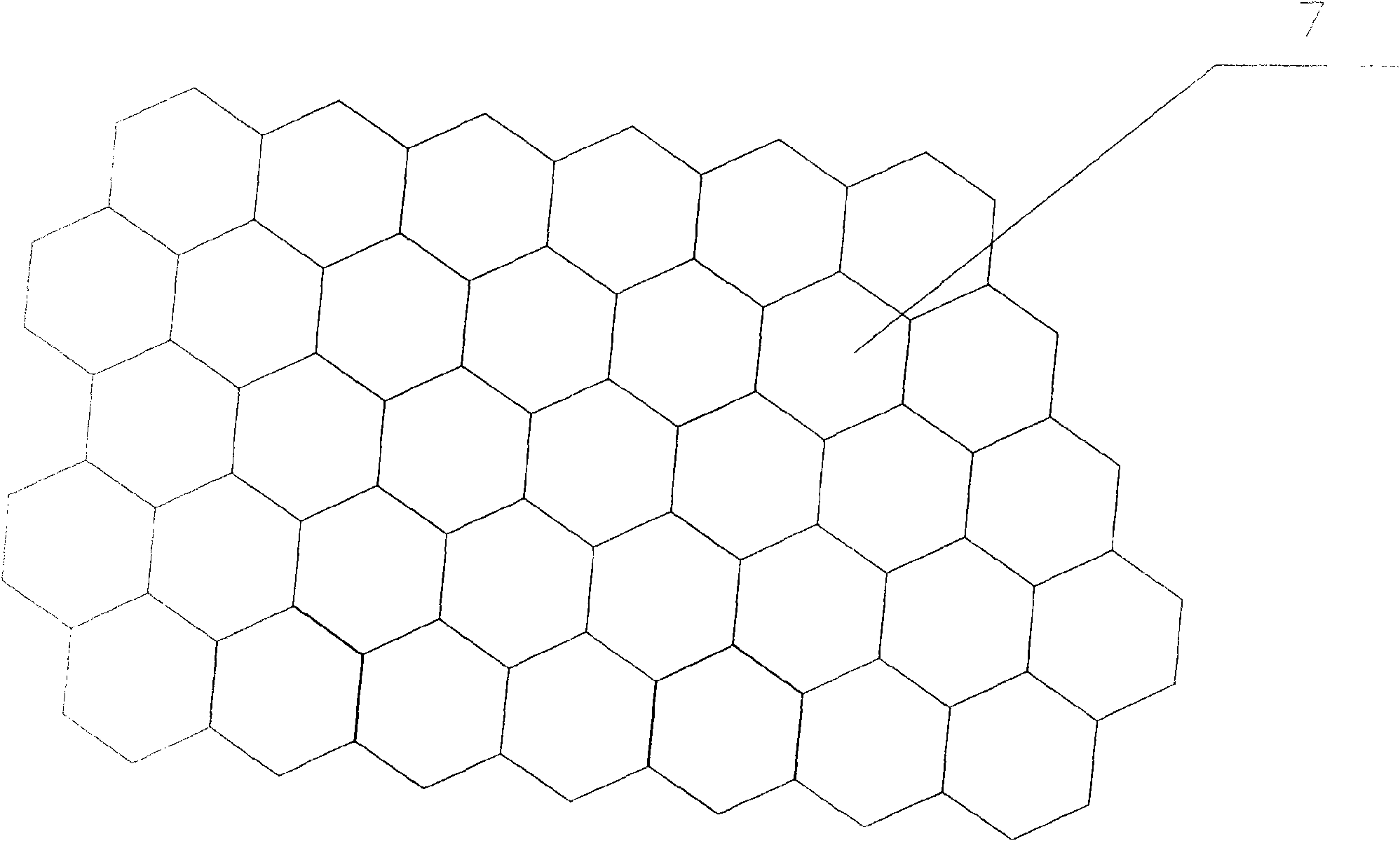

[0034] like figure 1 As shown, a honeycomb composite clean wall panel of the present invention, the clean panel includes a face plate 1 and a bottom plate 2, and the face plate and the bottom plate are directly provided with at least one honeycomb core layer 3, and the outer honeycomb layer between the face plate and the bottom plate A circle of metal keel 4 is arranged on the edge.

[0035] From top to bottom, the clean board is: panel 1, environmental protection adhesive layer 5, honeycomb core layer 3, environmental protection adhesive layer 6 and bottom plate 2, and the honeycomb core layer passes through the environmental protection adhesive layer and panel and Base plate composite.

[0036] Both the panel and the bottom plate are color steel plates.

[0037] The environmentally friendly adhesive is PVR glue, two-component latex or cornstarch modified glue.

[0038] The honeycomb core is a paper, plastic or metal sheet honeycomb core.

[0039] like figure 2 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com