Biomass slurry atomization thermal cracking process and device

A biomass and thermal cracking technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of uneven and stable temperature field, uneven material mixing, high equipment investment costs, etc., and achieve stable temperature field and compact equipment structure , the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

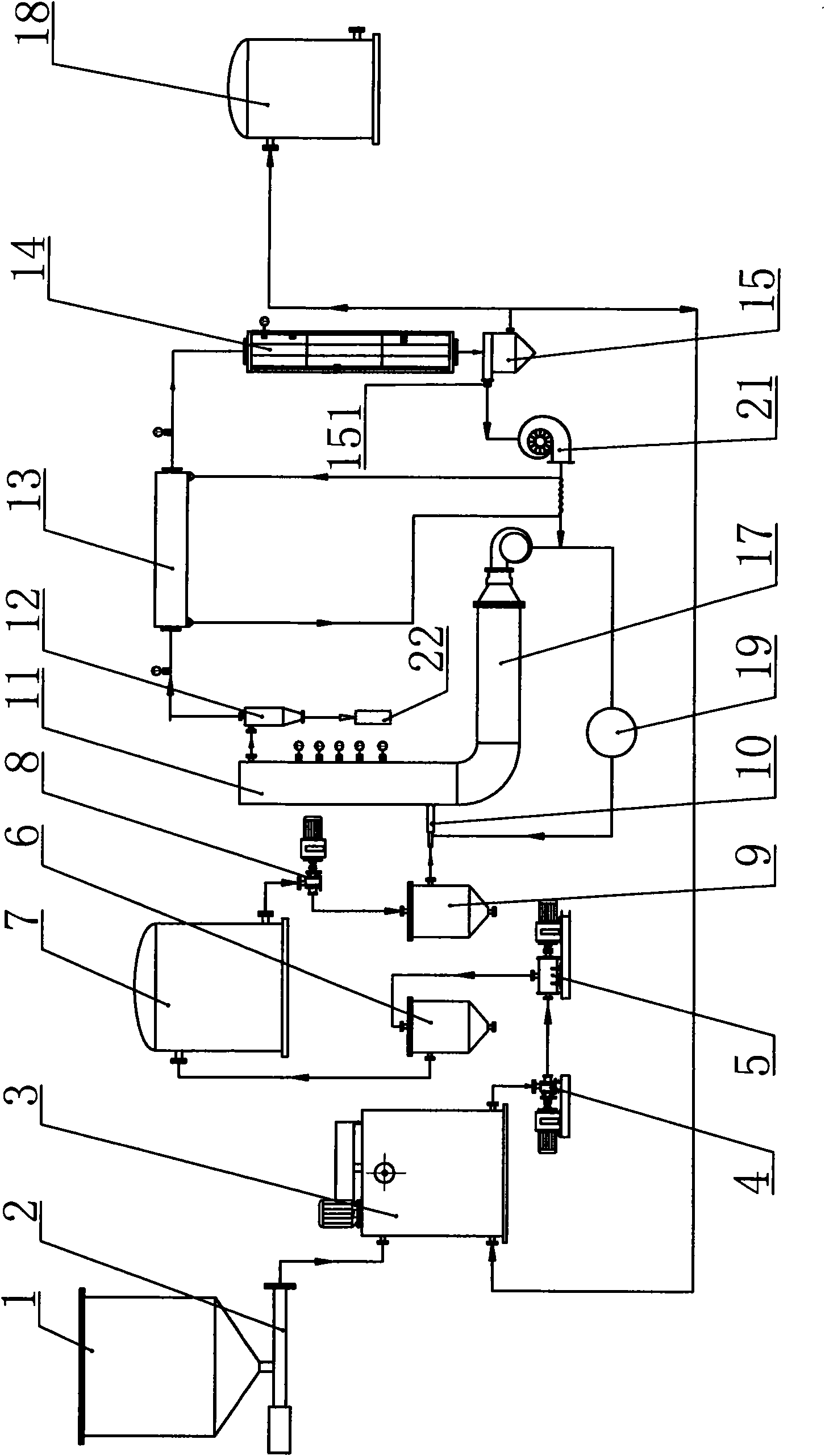

[0024] see figure 1 , the basic technological process of the present invention is:

[0025] (1) Stirring and mixing: the biomass powder and biomass oil are mixed according to an appropriate ratio to form slurry biomass.

[0026] (2) Gasification: the slurry biomass is sent into a pyrolysis reactor to be gasified under the action of high-temperature gas.

[0027] (3) Gas-solid separation: use a cyclone separator to separate the gasified biomass into some carbon particles and biomass-containing gas, and use a carbon collector to collect the separated part of the carbon particles.

[0028] (4) Condensation and oil collection: use the gas-water heat exchanger and oil collector to condense the biomass-containing gas into biomass fuel oil in sequence.

[0029] The biomass includes crop stalks, other plant stalks, branches and sawdust.

[0030] see figure 2 , a specific process embodiment of the present invention comprises:

[0031] 1. The 30-50 mesh biomass powder is continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com