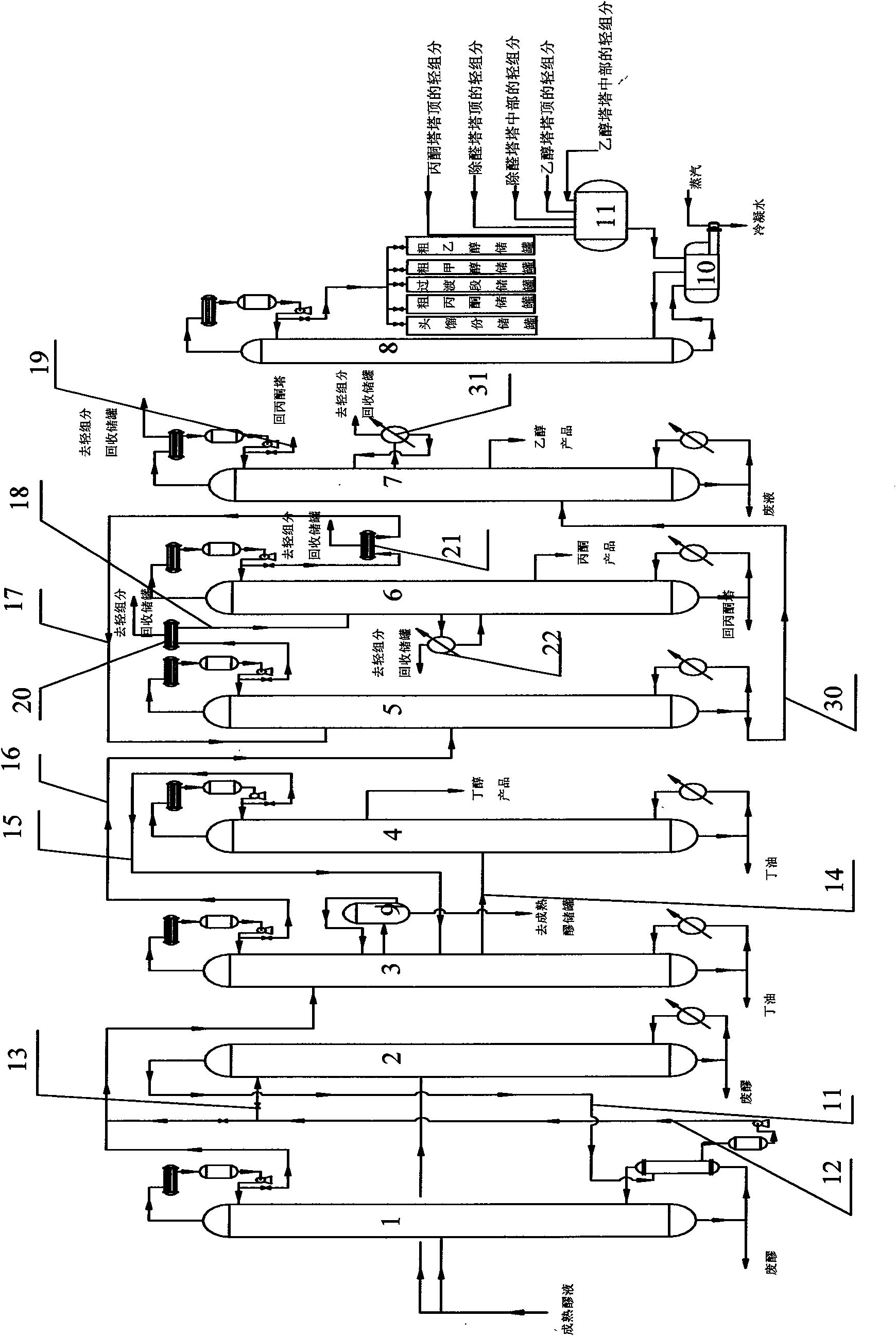

Separating and purifying method of butyl alcohol, acetone and total ethanol dissolvent in corn fermentation mash and device thereof

A technology for fermentation mash and total solvent, applied in the separation/purification of hydroxyl compounds, separation/purification of carbonyl compounds, chemical instruments and methods, etc., can solve the problems of low mass transfer separation efficiency and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030](a) prepare mature mash, the composition of described mature mash is 97.9% water, 1.2% butanol, 0.6% acetone, 0.2% ethanol, and the balance is impurity, and impurity comprises methyl alcohol, acetic acid, butyric acid, isoamyl alcohol, etc.; (b) divide the mature mash into two streams at a flow rate of 250kg / h and 350kg / h respectively, and pump the material with a small flow rate into the middle part of the crude mash rectification tower A after being preheated to a temperature of 68°C After the preheating temperature of the material with a large flow rate reaches 95°C, it is pumped into the middle of the crude mash rectification B tower, and after a dehydration, the total solvent mass percentage is extracted from the top of the crude mash rectification A tower and B tower respectively Concentration is controlled at 45% of the material, and part of the material extracted from the top of the crude mash rectification A tower is sent to the upper section of the butanol recti...

Embodiment 2

[0033](a) prepare mature mash, the composition of described mature mash is 97.9% water, 1.2% butanol, 0.6% acetone, 0.2% ethanol, and the balance is impurity, and impurity comprises methyl alcohol, acetic acid, butyric acid, isoamyl alcohol, etc.; (b) divide the mature mash into two streams at a flow rate of 300kg / h and 420kg / h respectively, and pump the material with a small flow rate into the middle part of the crude mash rectification A tower after the preheating temperature reaches 70°C After the preheating temperature of the material with a large flow rate reaches 97°C, it is pumped into the middle of the crude mash rectification B tower, and after a dehydration, the total solvent mass percentage is extracted from the top of the crude mash rectification A tower and B tower respectively Concentration is controlled at 50% of the material, the material extracted from the top of the crude mash rectification A tower is partly sent to the upper section of the butanol rectificati...

Embodiment 3

[0036](a) prepare mature mash, the composition of described mature mash is 97.9% water, 1.2% butanol, 0.6% acetone, 0.2% ethanol, and the balance is impurity, and impurity comprises methyl alcohol, acetic acid, butyric acid, isoamyl alcohol, etc.; (b) divide the mature mash into two streams at a flow rate of 350kg / h and 490kg / h respectively, and pump the material with a small flow rate into the middle part of the crude mash rectification tower A after being preheated to a temperature of 72°C After the preheating temperature of the material with a large flow rate reaches 99°C, it is pumped into the middle of the crude mash rectification B tower, and after a dehydration, the total solvent mass percentage is extracted from the top of the crude mash rectification A tower and B tower respectively Concentration is controlled at 55% of the material, and the material extracted from the top of the crude mash rectification A tower is partly sent to the upper section of the butanol rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com