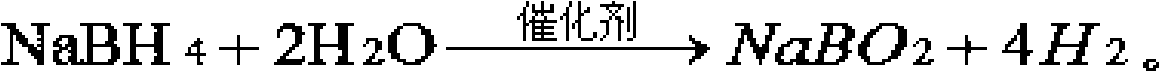

Alkali-removing method used for hydrogen production by borohydride

A technology of borohydride and sodium borohydride, applied in the production of hydrogen, the use of solid contact hydrogen separation, hydrogen separation, etc., can solve the problems of acid liquid easily entering the fuel cell stack or hydrogen generator, damaging hydrogen production equipment, etc. , to achieve the effect of small volume and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Sodium borohydride is hydrolyzed to produce hydrogen. The hydrogen generation rate is 1.4L / min. The hydrogen passes through a purification device to remove the lye contained in it. The purification device is a plexiglass tube with 7.2g SO in the middle part 4 2- / ZrO 2 Solid super acid, the front end of the glass tube is filled with heat-bonded dust-free paper with high absorption resin, and the back end of the glass tube is filled with absorbent cotton. Continuous and stable operation for 150 minutes, the purified hydrogen was passed into a certain amount of deionized water, the pH value of the deionized water did not change, indicating that the hydrogen removal rate was 100%.

Embodiment 2

[0020] Sodium borohydride is hydrolyzed to produce hydrogen. The generation rate of hydrogen is 2L / min. The hydrogen passes through a purification device to remove the lye contained in it. The purification device is a plexiglass tube with 15g AlCl filled in the middle part of the inside. 3 -CuCl 2 Compound type solid super acid, the front end of the glass tube is filled with heat-sealing dust-free paper of high absorption resin, and the back end of the glass tube is filled with absorbent cotton. After continuous and stable operation for 120 minutes, the purified hydrogen was passed into a certain amount of deionized water. The pH value of the deionized water did not change, indicating that the hydrogen removal rate was 100%.

Embodiment 3

[0022] Sodium borohydride is hydrolyzed to produce hydrogen. The hydrogen generation rate is 1L / min. The hydrogen passes through a purification device to remove the lye contained in it. The purification device is a plexiglass tube with 5g SO in the middle part of the inside. 4 - / ZrO 2 / MCM-41, the front end of the glass tube is filled with 4A molecular sieve, and the rear end of the glass tube is filled with absorbent cotton. After continuous and stable operation for 180 minutes, the purified hydrogen was passed into a certain amount of deionized water. The pH value of the deionized water did not change, indicating that the hydrogen removal rate was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com