Intake and exhaust device of air breathing supersonic/hypersonic aerocraft

A technology of hypersonic speed and aircraft, which is applied to the exhaust port of the power unit, the combustion of the intake port of the power unit, etc., and can solve the problems of nozzle thrust drop, combustion efficiency deterioration, engine failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

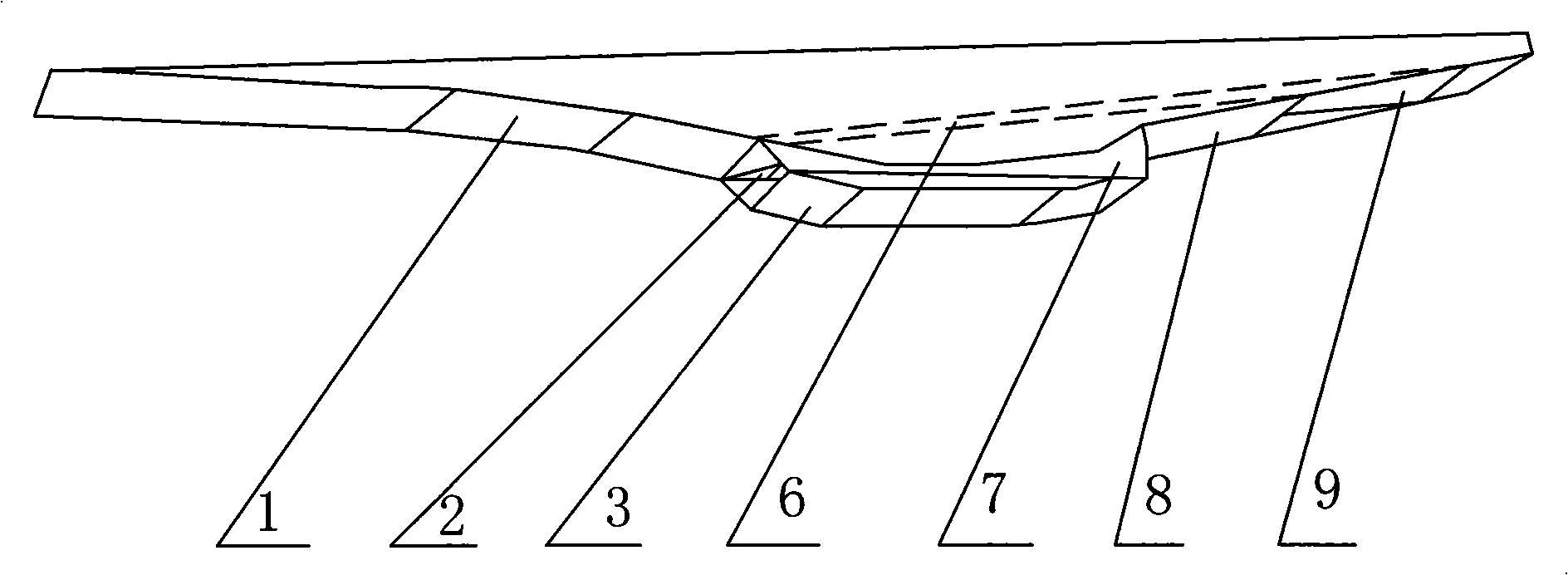

[0020] Such as figure 1 and figure 2 As shown, the air-breathing supersonic / supersonic aircraft air intake and exhaust device described in the present invention includes an inner flow channel arranged on the lower abdomen of the aircraft, and the inner flow channel includes an air intake channel connected in sequence, an isolation section 4, a combustion chamber 5 and the nozzle, the intake and exhaust device also includes a suction device connected between the air inlet and the nozzle and a control device for controlling the opening or closing of the suction device. When the air-breathing supersonic vehicle is working at the design point, the control device issues an instruction to close the suction device, and when the air-breathing supersonic vehicle is working at a non-design point, the control device issues an instruction to turn on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com