Turbo-charger single-stage prototype centrifugal compressor interstage pressure test structure

A technology of centrifugal compressor and turbocharger, which is applied in pump testing, machine/engine, measuring fluid pressure, etc. It can solve the problem of not finding the static pressure measurement between compressor stages, etc., and achieve the effect of simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

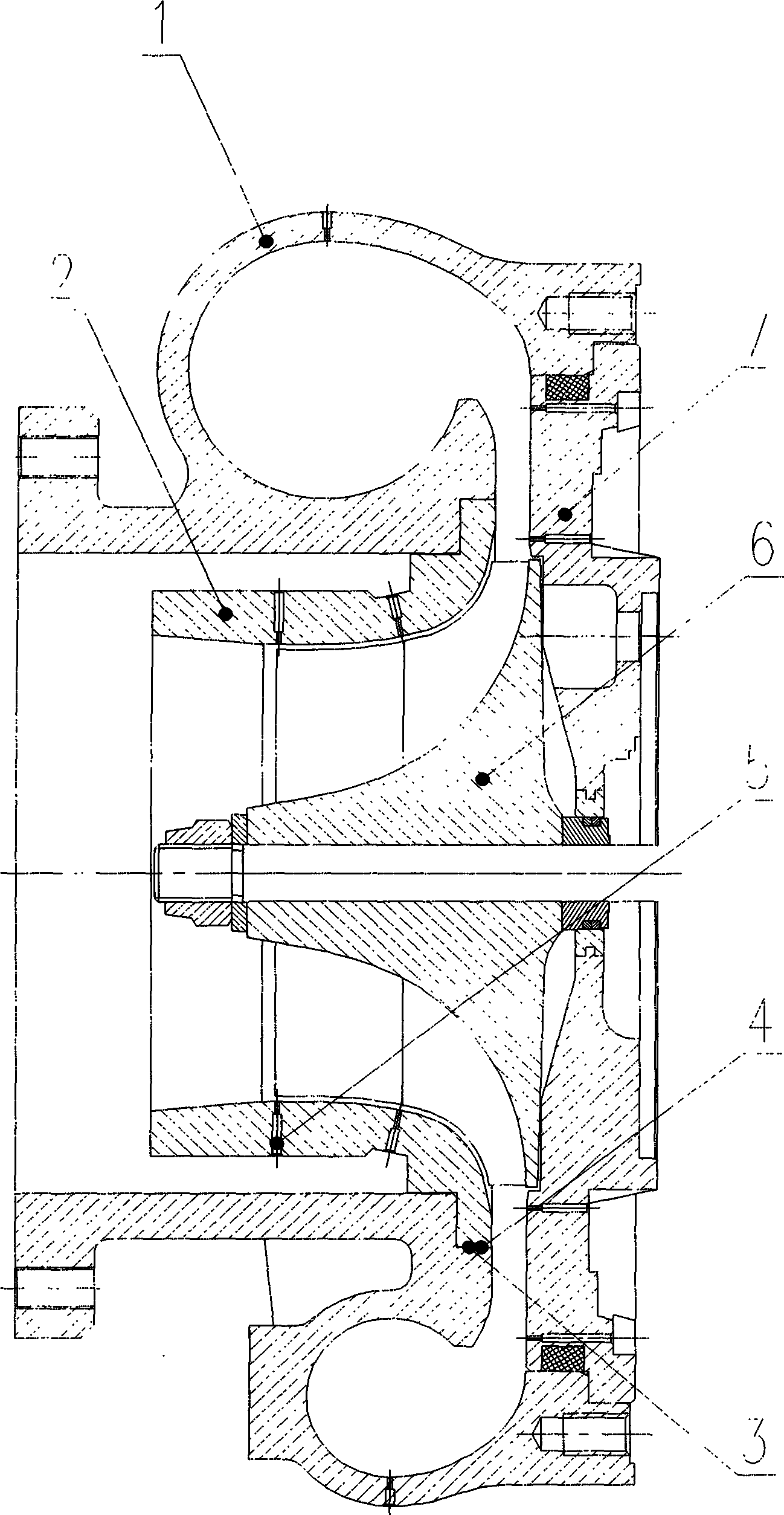

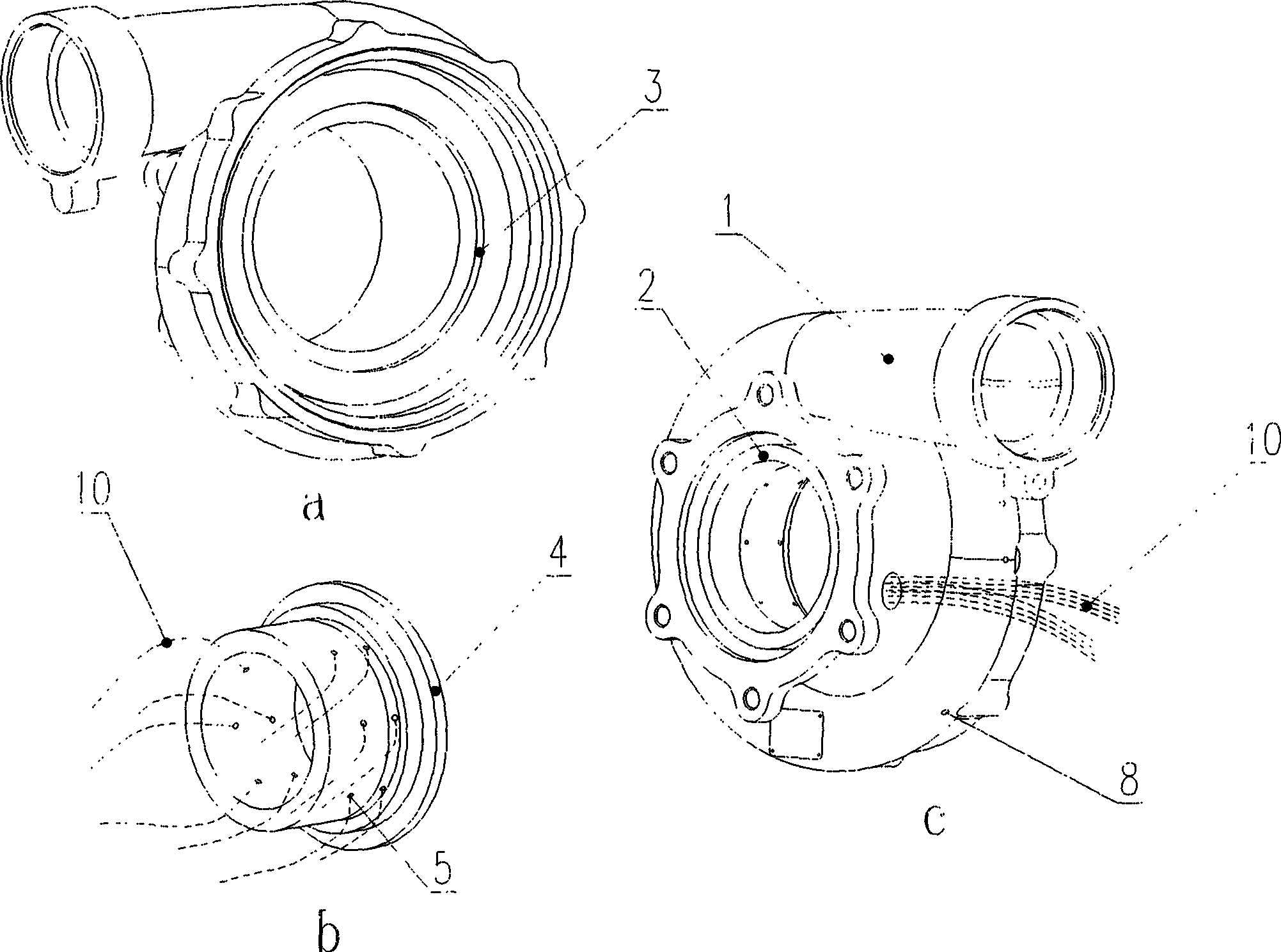

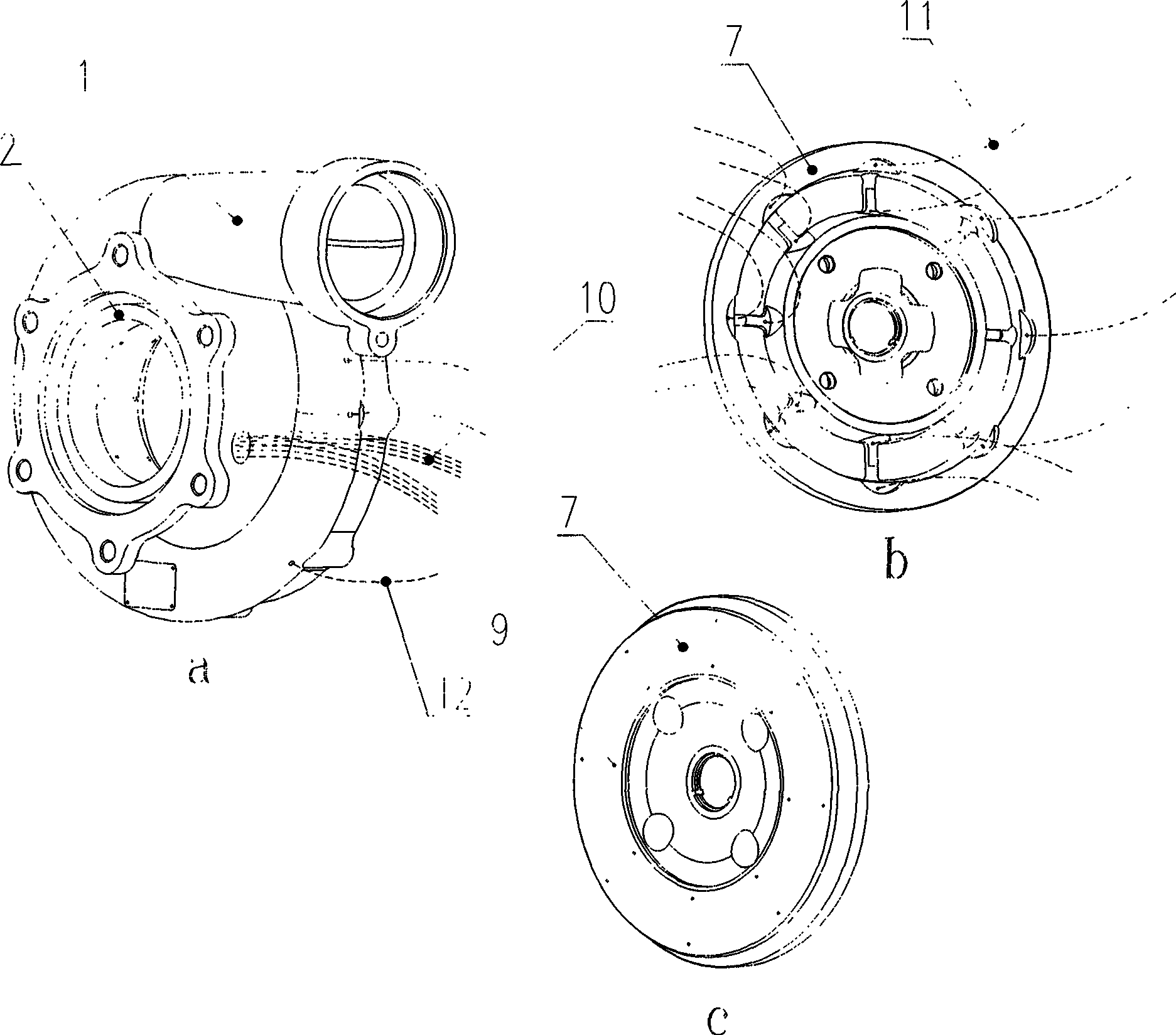

[0019] Such as figure 1 , figure 2 a. figure 2 b. figure 2 c. image 3 a. image 3 b. image 3 As shown in c, a turbocharger single-stage prototype centrifugal compressor interstage pressure test structure includes a compressor volute, a compressor impeller 6, and a compressor back plate 7, and the volute is fixed to the compressor back plate 7 by bolts Above, the compressor impeller 6 is fixed on the 7-axis sleeve of the compressor back plate through the shaft end nut, and the compressor volute is divided into a split volute 1 and a sleeve at a position of 180 mm in diameter in the middle of the side wall of the compressor volute diffuser 2 Two parts, the split volute 1 and the sleeve 2 are fixedly connected through the heat-fitting surface 3 of the split volute 1 and the contact surface 4 of the sleeve 2, and 8 are evenly distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com