Method for preparing fluorinated acrylate copolymer

A technology of fluorinated polyacrylate and butyl methacrylate, which is applied in the field of preparation of organic polymers, can solve the problems of complex process and difficult removal of polymerization product catalysts, and achieve the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

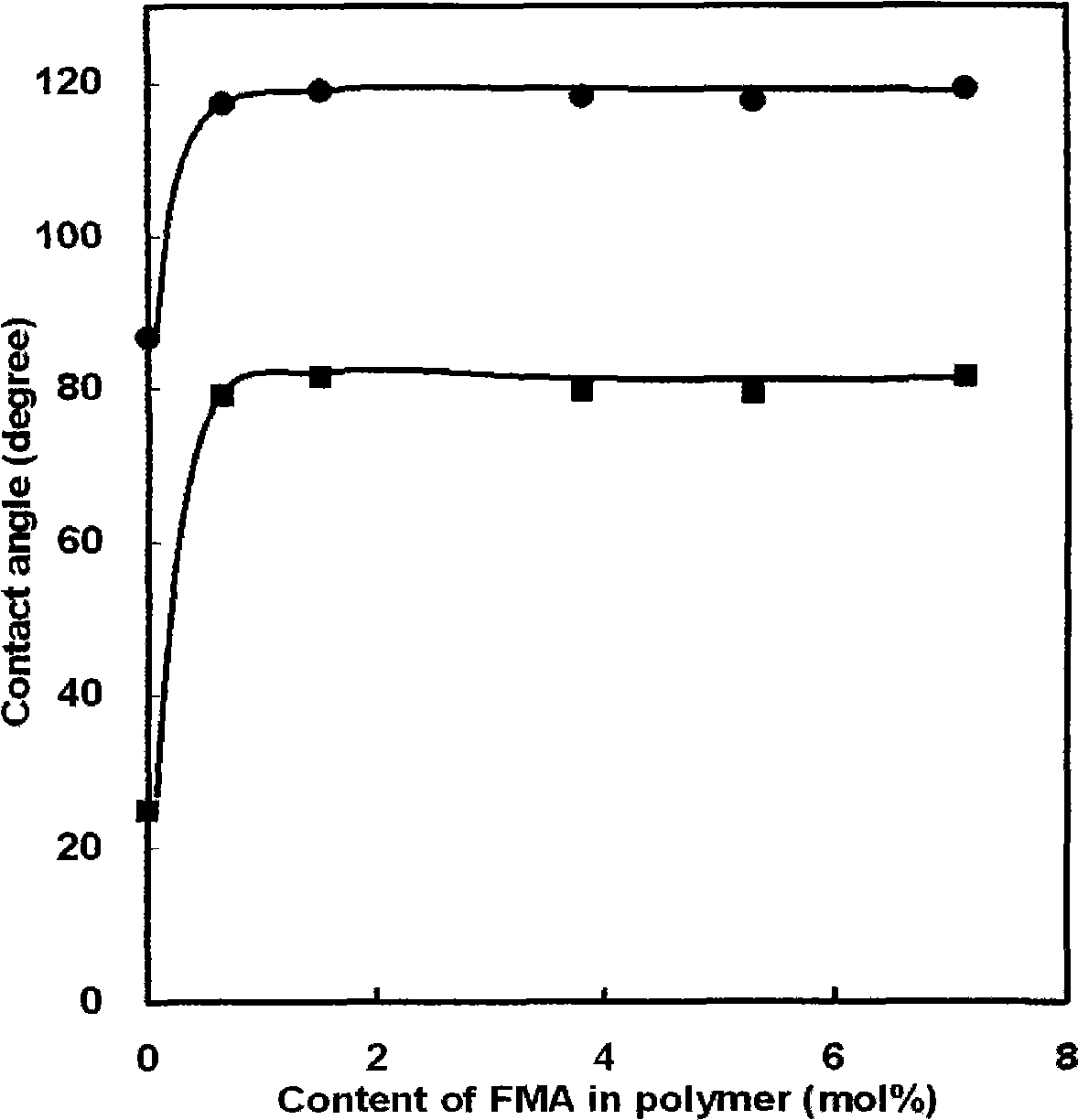

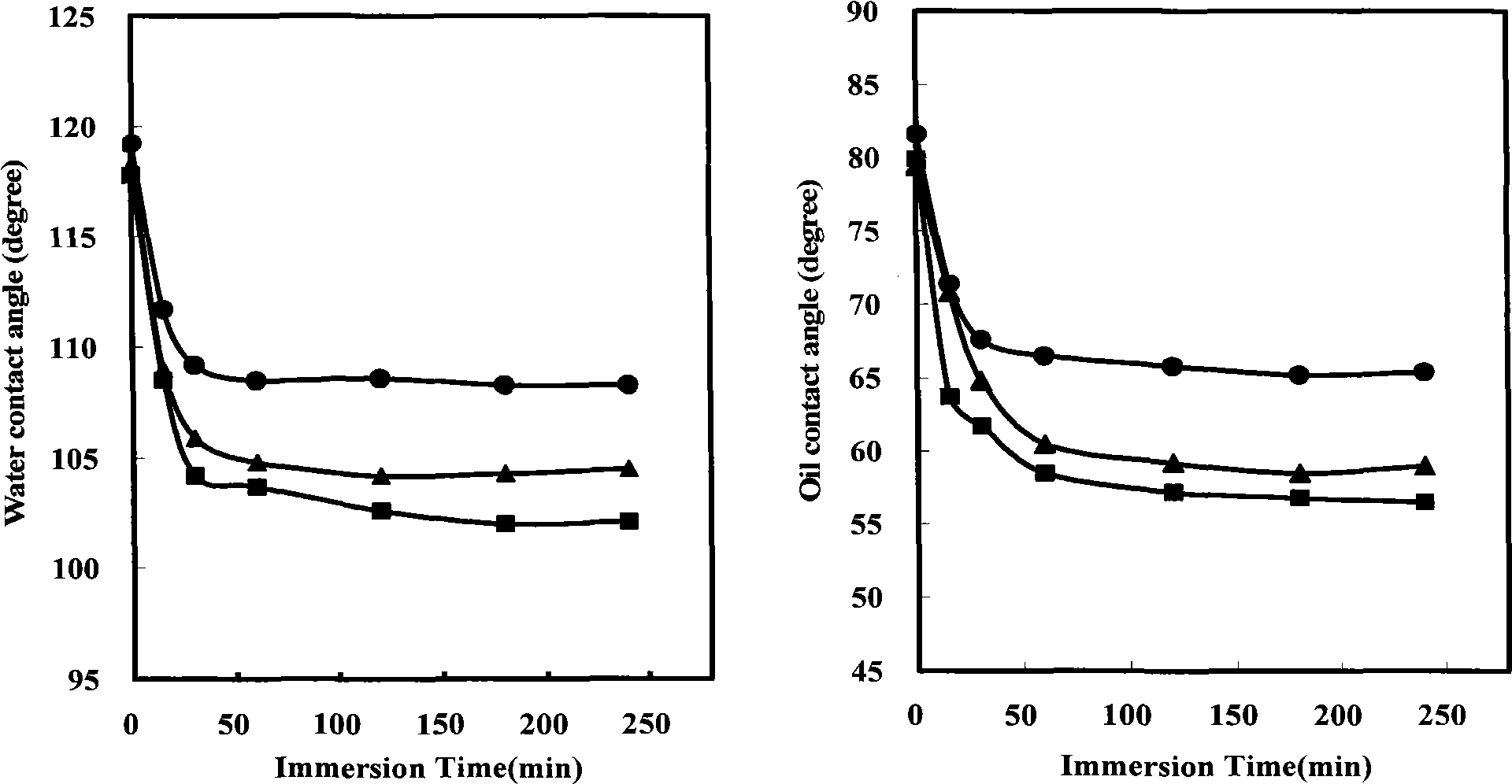

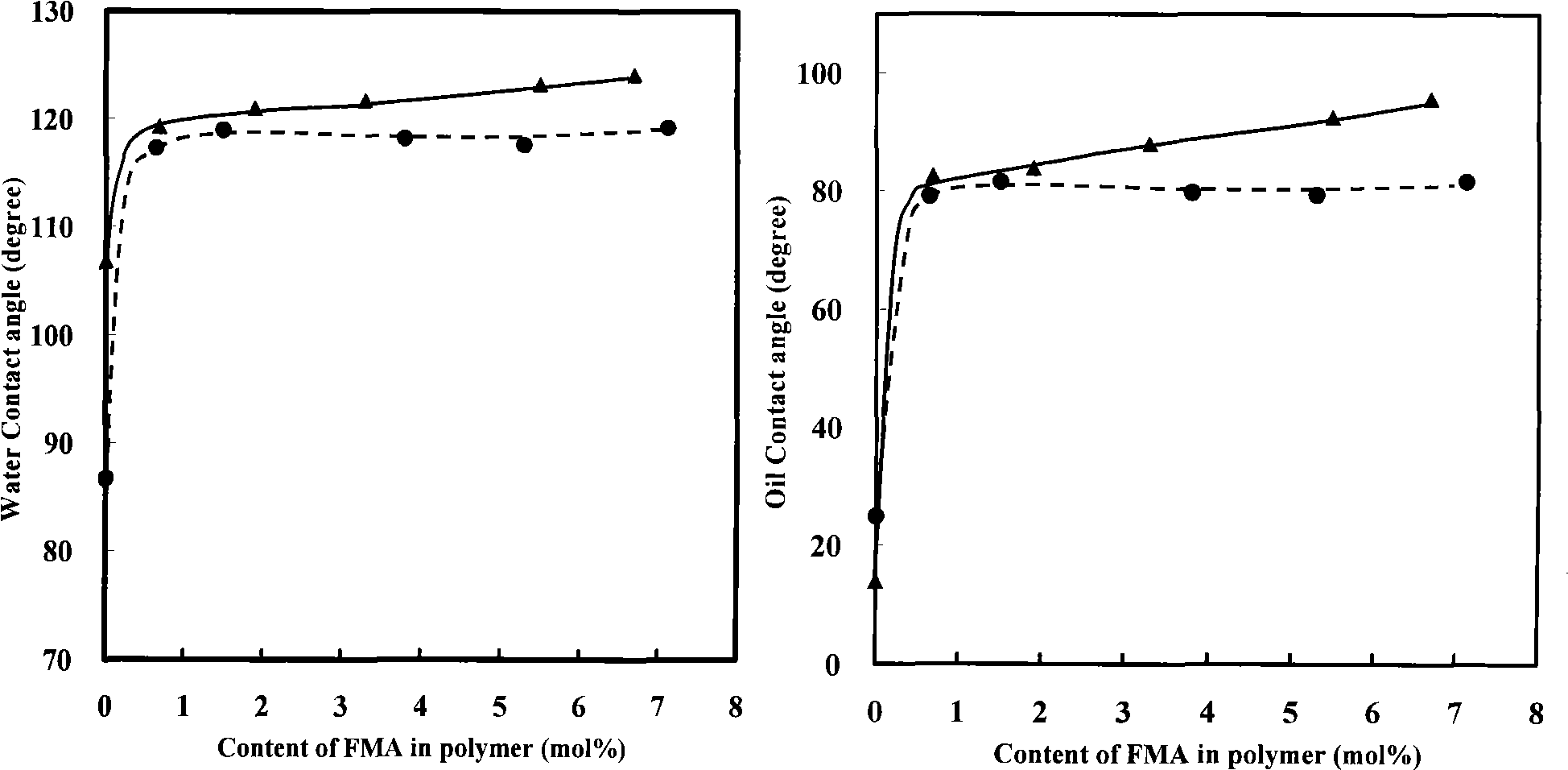

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the implementation of the present invention is described in detail:

[0030] Selection of raw materials:

[0031] (1) Select methyl methacrylate and butyl methacrylate monomers (MMA / BMA) and refine them. Add 100 mL of methacrylate monomer to a 250 mL separatory funnel and use 20 mL of 5% NaOH solution was washed several times until the aqueous layer was colorless. The purpose of washing with 5% NaOH solution is to remove the polymerization inhibitor in the monomer. Continue washing the methacrylate monomer with deionized water until the aqueous layer is neutral. Store in a brown bottle and store in the refrigerator for later use.

[0032] (2) select stearyl methacrylate (ODMA) for use, and carry out refining, the solid monomer is dissolved in normal hexane at first, extract several times with 5% NaOH aqueous solution, continue washing with deionized water, until the water layer is neutral. The solvent was removed by d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com