Production method of amino acid bio-organic fertilization fertilizer

A production method and fertilization technology, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of heavy air pollution, increased soil diseases, and large output, so as to reduce production costs, improve soil structure, and produce products The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

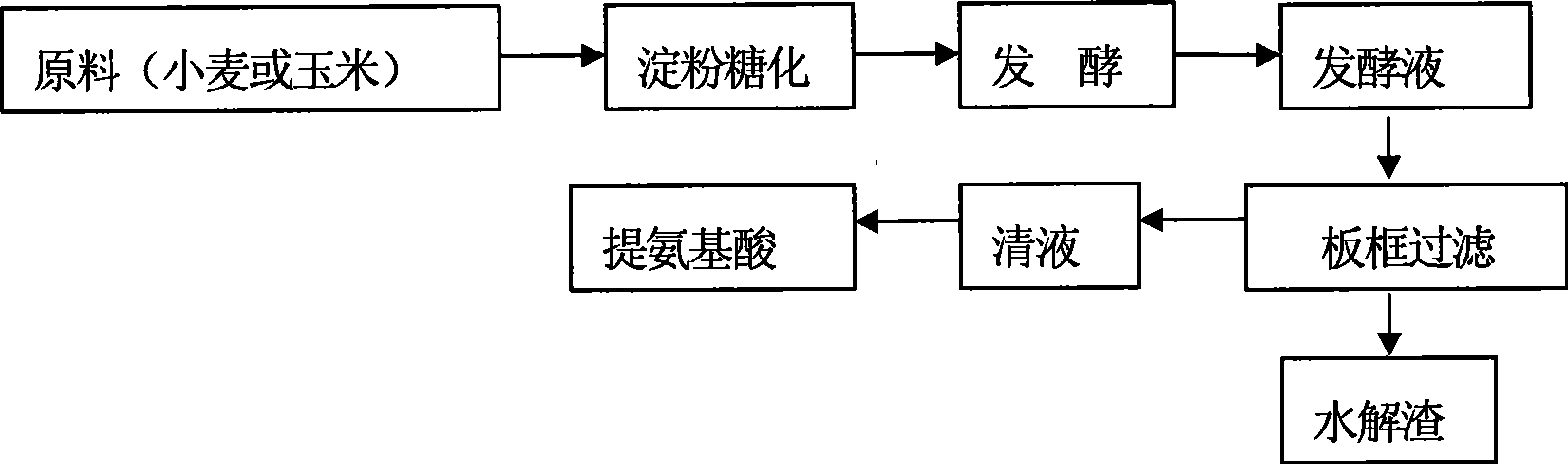

Method used

Image

Examples

Embodiment 1

[0028] 1. Sampling: The hydrolyzed slag was taken from Henan Lianhua Amino Acid Co., Ltd.

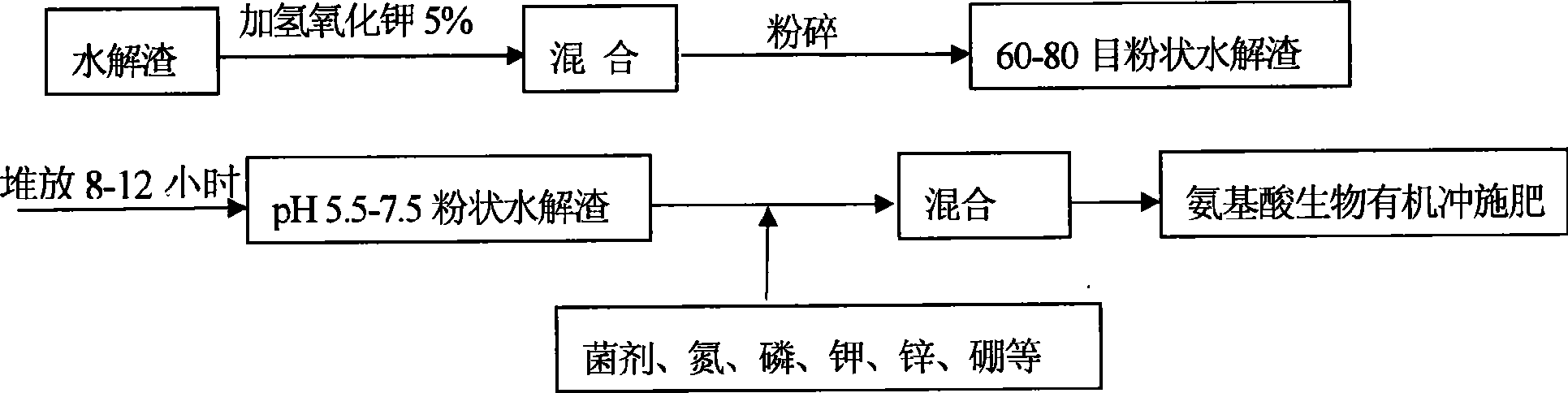

[0029] 2. pH adjustment: Add 5% potassium hydroxide to the hydrolyzed slag, mix it, grind it to 80 mesh with a chain crusher, and stack it for 8-12 hours to allow it to fully react. The basic properties of the hydrolyzed slag after treatment are shown in Table 1.

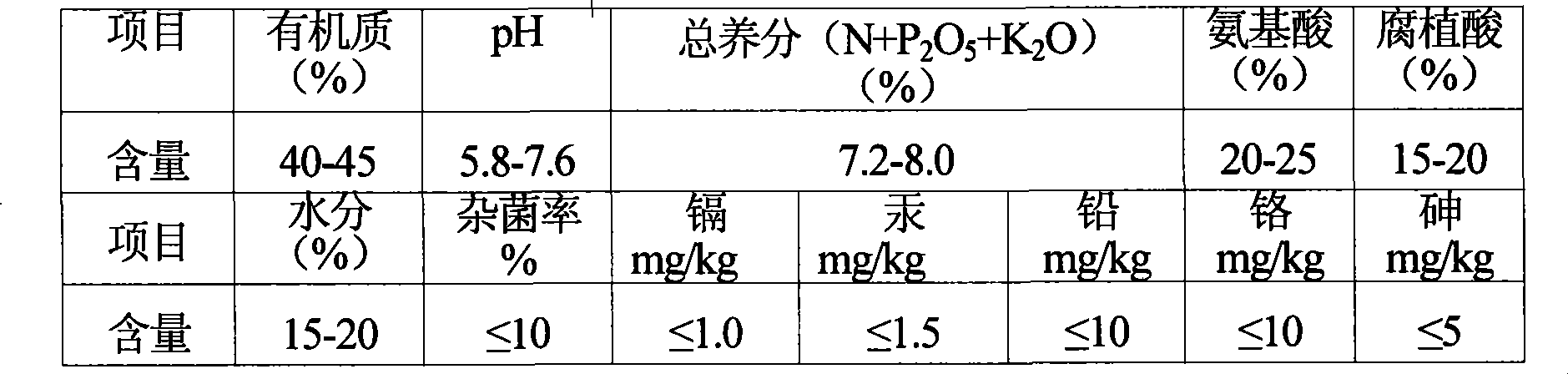

[0030] Table 1 Basic properties of hydrolyzed slag (powder) after treatment

[0031]

[0032] 3. Turn over: Use a forklift or manually turn over the pile, let the temperature of the reacted material cool down to normal temperature, and make the pH reach 5.5-7.5;

[0033]4. Preparation of compound microbial bacterial agent: Bacillus subtilis and Bacillus mucilaginosus are produced by separate fermentation using fermentation equipment, and the fermented bacterial liquid is respectively pressed with 80-mesh rice husk powder: rice husk Powder = 1:3 ratio for adsorption, mix the two adsorbed single bacterial agents according ...

Embodiment 2

[0044] Add 6% potassium hydroxide to the hydrolyzed slag and mix it, pulverize it to 100 mesh with a chain crusher and stack it for 8-12 hours to allow it to fully react;

[0045] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:2.5, and they are crushed to 100 mesh after mixing. The fineness of rice husk powder is 100 mesh, and the adsorption ratio of bacterial agent to rice husk powder is 1:5.

[0046] The adding ratio of bacterial agent is 6%, and the adding ratio of hydrolyzed slag is 64%, and other is with embodiment 1.

Embodiment 3

[0048] Add 6% potassium hydroxide to the hydrolyzed slag, mix it with a chain crusher to 120 mesh, and stack it for 8-12 hours to allow it to fully react;

[0049] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 1:1.5, and they are crushed to 120 mesh after mixing. The fineness of rice husk powder is 120 mesh, and the adsorption ratio of bacterial agent to rice husk powder is 1:4.

[0050] The addition ratio of bacterial agent is 8%, and the addition ratio of hydrolysis slag is 63%, and the addition ratio of urea is 14%, and other is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com