Brand-new greenhouse soilless culture-fog culture technology

A soilless cultivation and greenhouse technology, applied in the field of soilless cultivation of plants, can solve the problems of easy deterioration of nutrient solution, inverse ratio, and only cultivation of water-loving plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

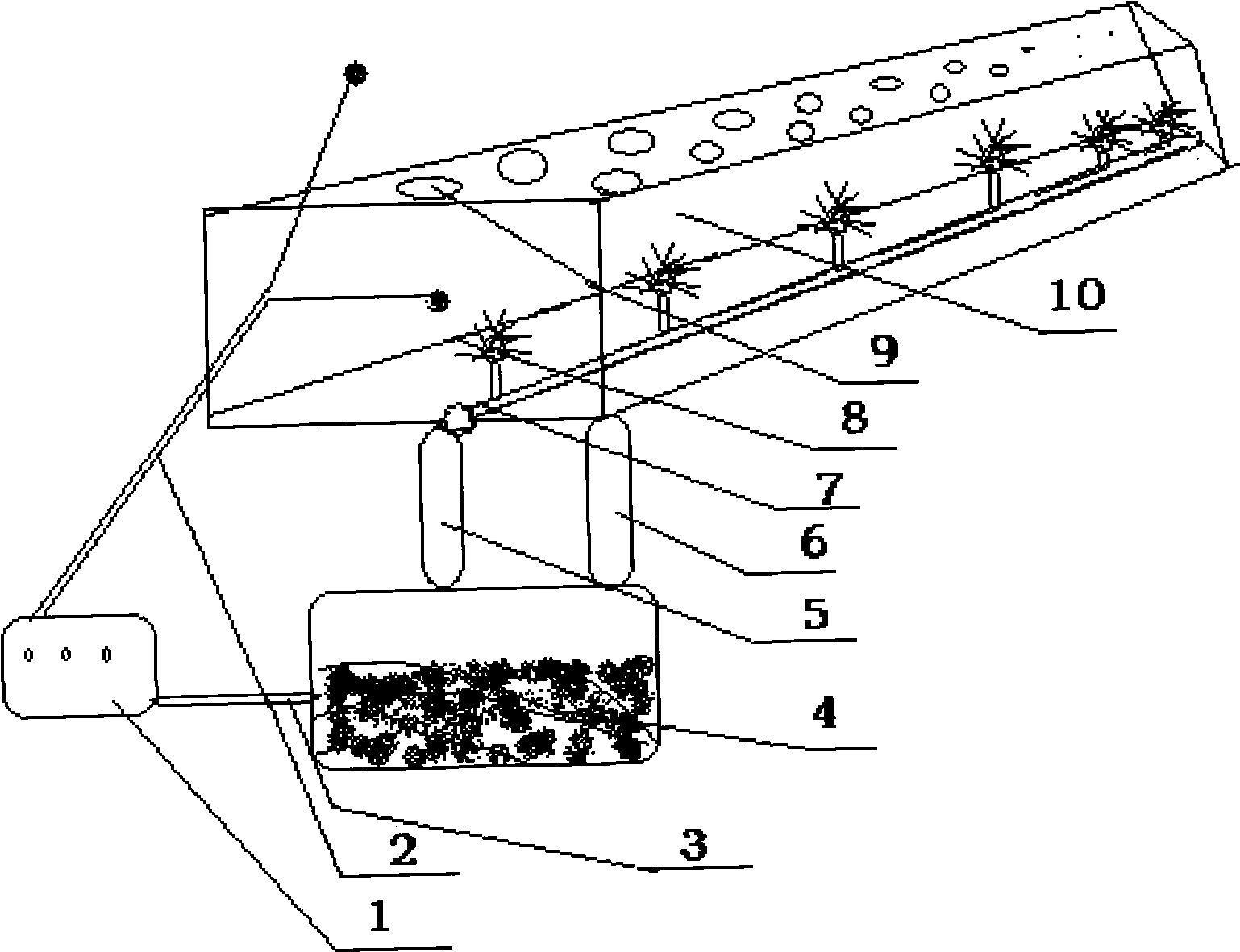

[0022] Embodiment 1: the use of the spray cultivation technique of the present invention in the trough cultivation system

[0023] In the constructed greenhouse, connect the data line 3 and the sensor 2 to the operation center 1, then connect the data line 3 to the nutrient solution supply system device 4, and finally connect the liquid supply pipe 5 and Return pipe 6 and cultivation system trough type (trough type: it is to build a 1.5m wide, 20-30cm high, long (according to the length of the greenhouse) brick cement trough on the flat ground of the greenhouse, and the bottom of the trough is built with a slight slope and no leakage On the cement bottom of the tank, a nutrient solution return hole is left at the slightly lower end of the tank for the return and collection of the nutrient solution. Spray pipes are laid on the bottom of the tank and an atomizing nozzle that sprays upwards is installed to ensure that the entire inner space of the tank can be used for cultivation....

Embodiment 2

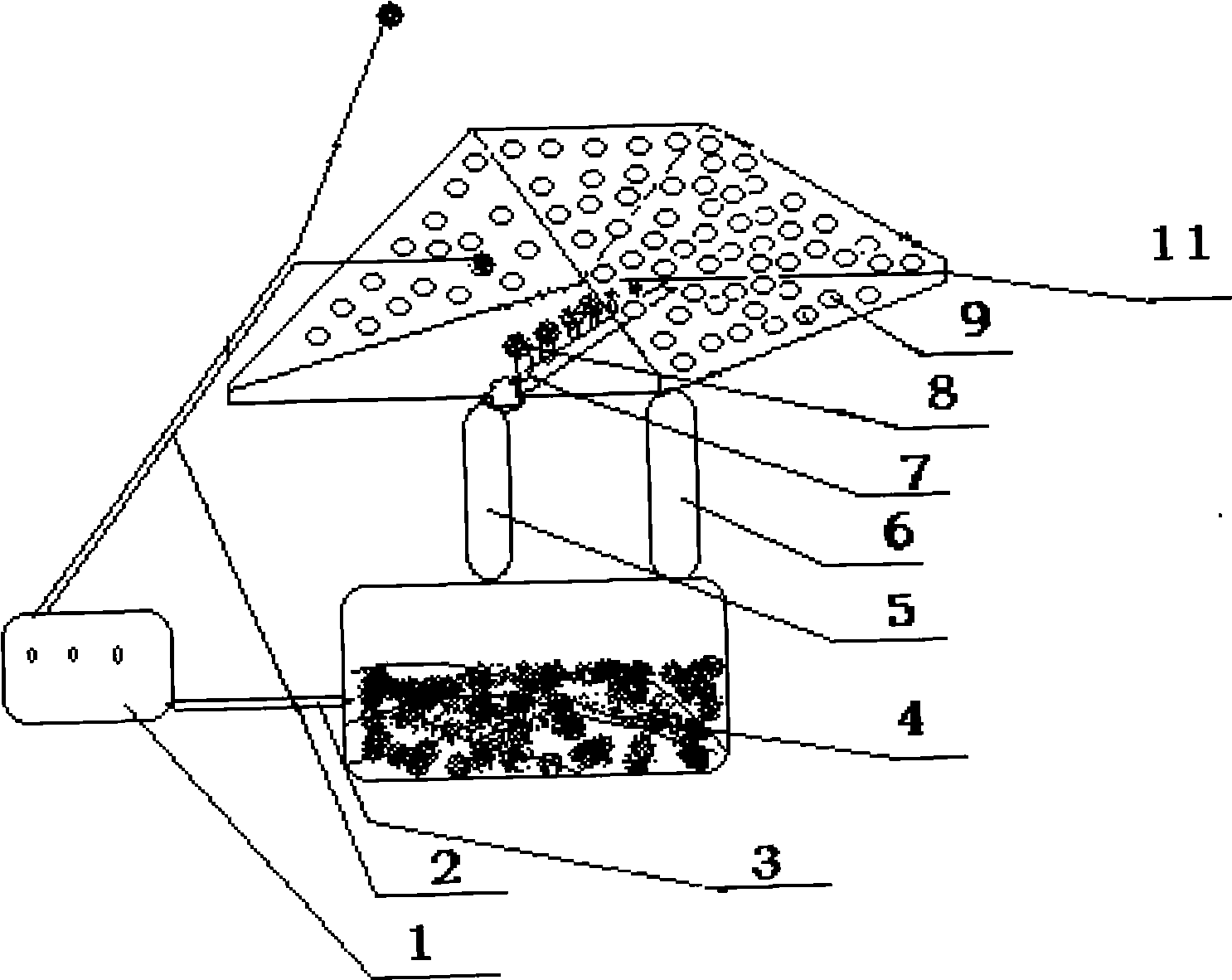

[0024] Embodiment 2: the use of spray cultivation technique of the present invention in tower cultivation system

[0025] In the constructed greenhouse, connect the data line 3 and the sensor 2 to the operation center 1, then connect the data line 3 to the nutrient solution supply system device 4, and finally connect the liquid supply pipe 5 and The return pipe 6 and the cultivation system tower type (tower type: choose plastic foam board as the material, punch holes on the board according to the planting density, and buckle the inverted V-shaped buckle of the planting board on the built support, which is made of profile Lay a thin film along the bottom surface of the frame or bricks to collect the returning nutrient solution. Suspend the mist pipe in the center of the tower to achieve uniform atomization without leaving any dead ends, and plant the crops wrapped with sponges in the planting hole) 11 connections.

Embodiment 3

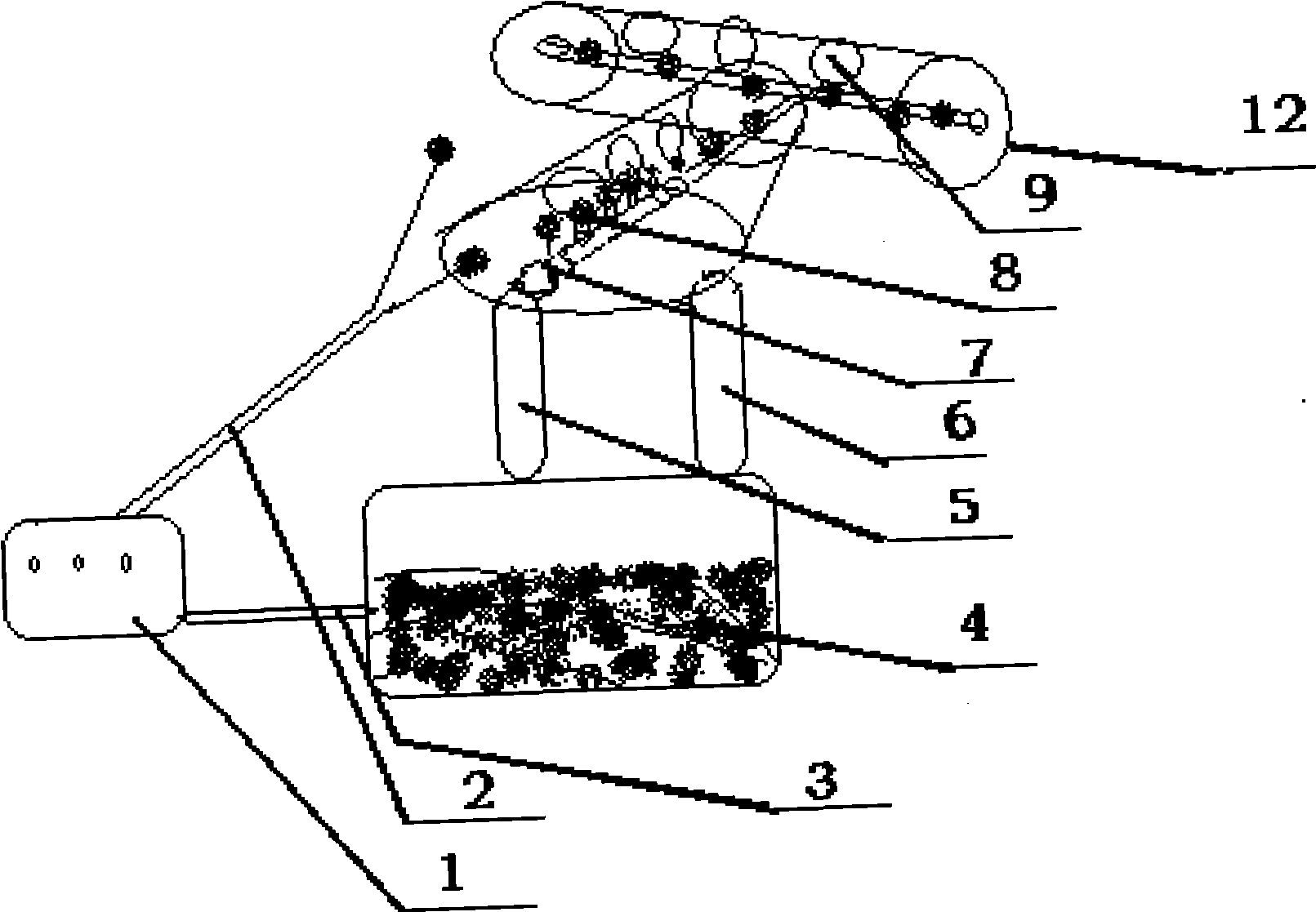

[0026] Embodiment 3: the use of spray cultivation technology of the present invention in pipeline cultivation system

[0027] In the constructed greenhouse, connect the data line 3 and the sensor 2 to the operation center 1, then connect the data line 3 to the nutrient solution supply system device 4, and finally connect the liquid supply pipe 5 and Return pipe 6 is connected with cultivation system pipeline type (pipeline type: use plastic pipe as root region space, micro-nozzle pipe is installed in the pipeline, and the crop that is bound with sponge is planted in the planting hole on the pipe mouth of perforation) 12 again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com