Solid electrolyte direct carbon fuel cell

A solid electrolyte and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of high volatility and high corrosion of molten electrolyte, and achieve the effects of reduced emissions, simple operation, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

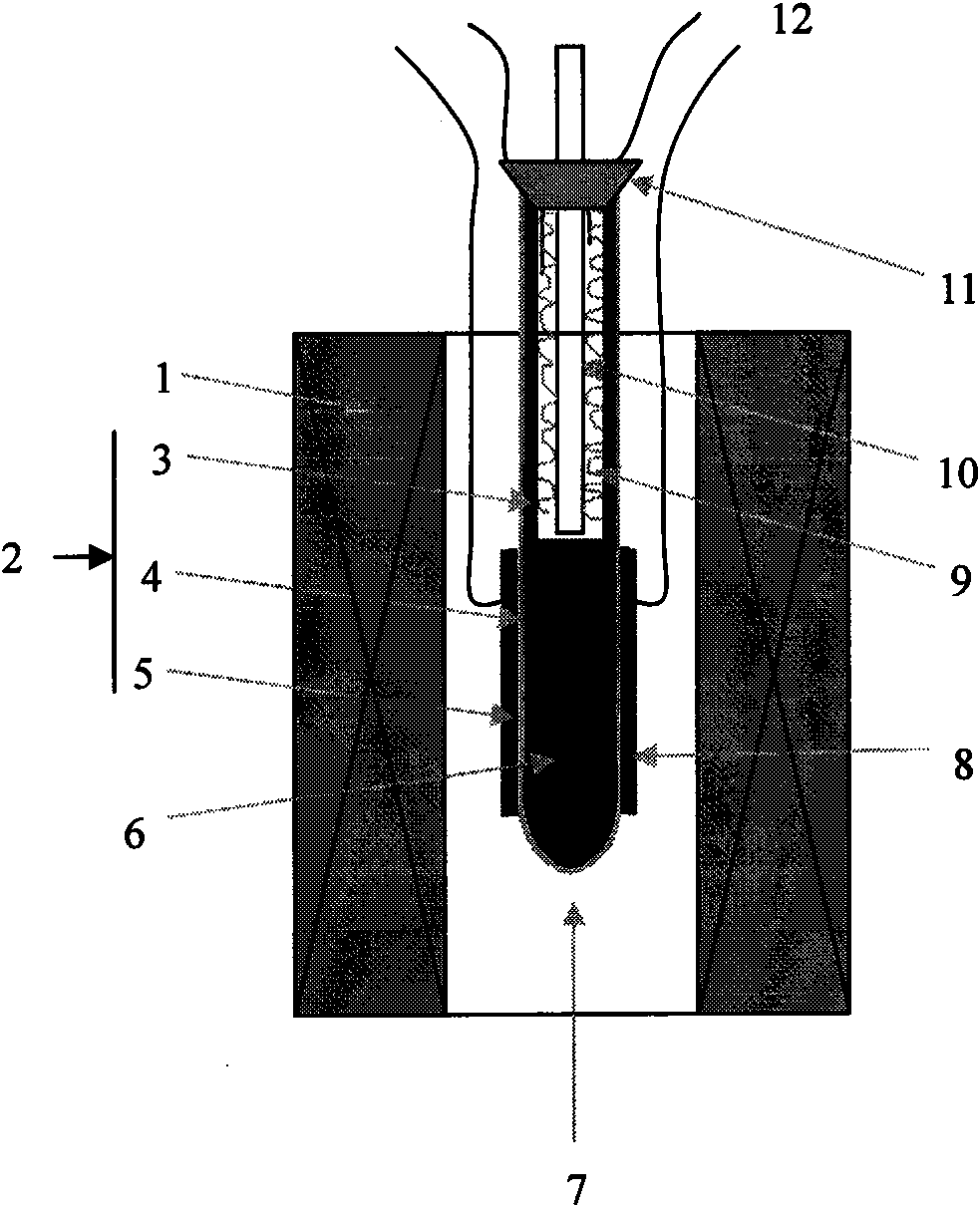

[0046] Example 1 Direct carbon fuel cell in which graphite is directly used as fuel

[0047] The structure prepared by dip molding method is: NiO-YSZ / SSZ / LSM-SSZ tubular solid oxide fuel cell, the cell wall thickness is about 0.5-0.8mm, the outer diameter is about 1.0cm, the length is about 12cm, and the cathode area is 10cm 2 . Graphite powder is filled in the tubular battery and is in direct contact with the anode of the battery. When the temperature is high, the battery is sealed with a high-temperature sealing material, and the inside of the battery is connected with the outside by a pressure balance tube. When there is a lot of reformed gas generated, it can be collected in a container; The reformed gas is passed into the pipe. Oxygen was fed into the cathode at 60 ml / min. When the battery is working, a small amount of water is added to the inside of the battery, so that carbon and water first undergo a reformation reaction inside the battery, and the electricity gener...

Embodiment 2

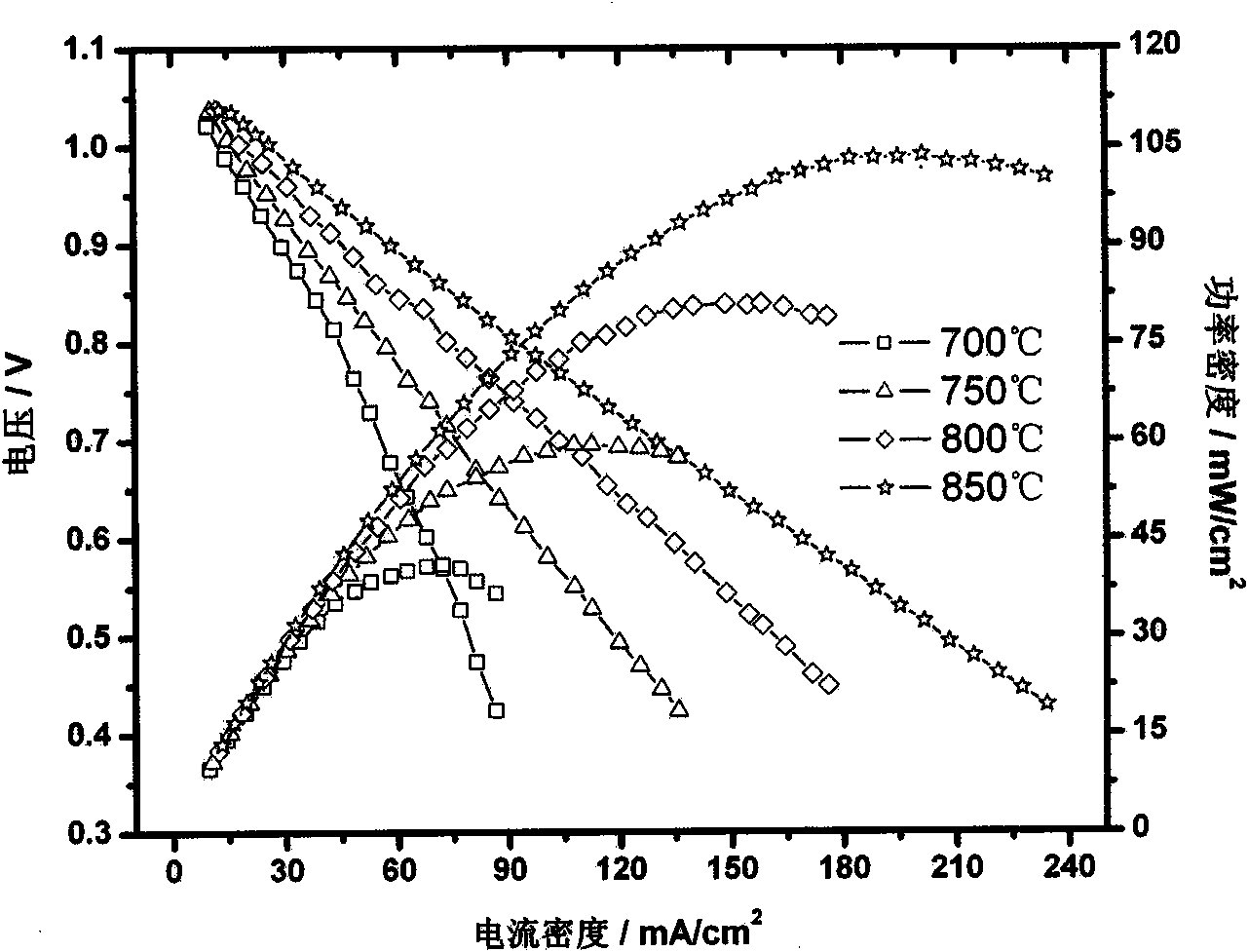

[0048] Example 2 Direct carbon fuel cell in which carbon black is directly used as fuel

[0049] On the basis of Example 1, the battery increases the anode active layer structure, that is, the structure is: a tubular solid oxide fuel cell of NiO-YSZ / NiO-SSZ / SSZ / LSM-SSZ, and then the graphite fuel is changed to carbon black fuel Perform a power generation test. Its electrical properties are as attached image 3 shown.

Embodiment 3

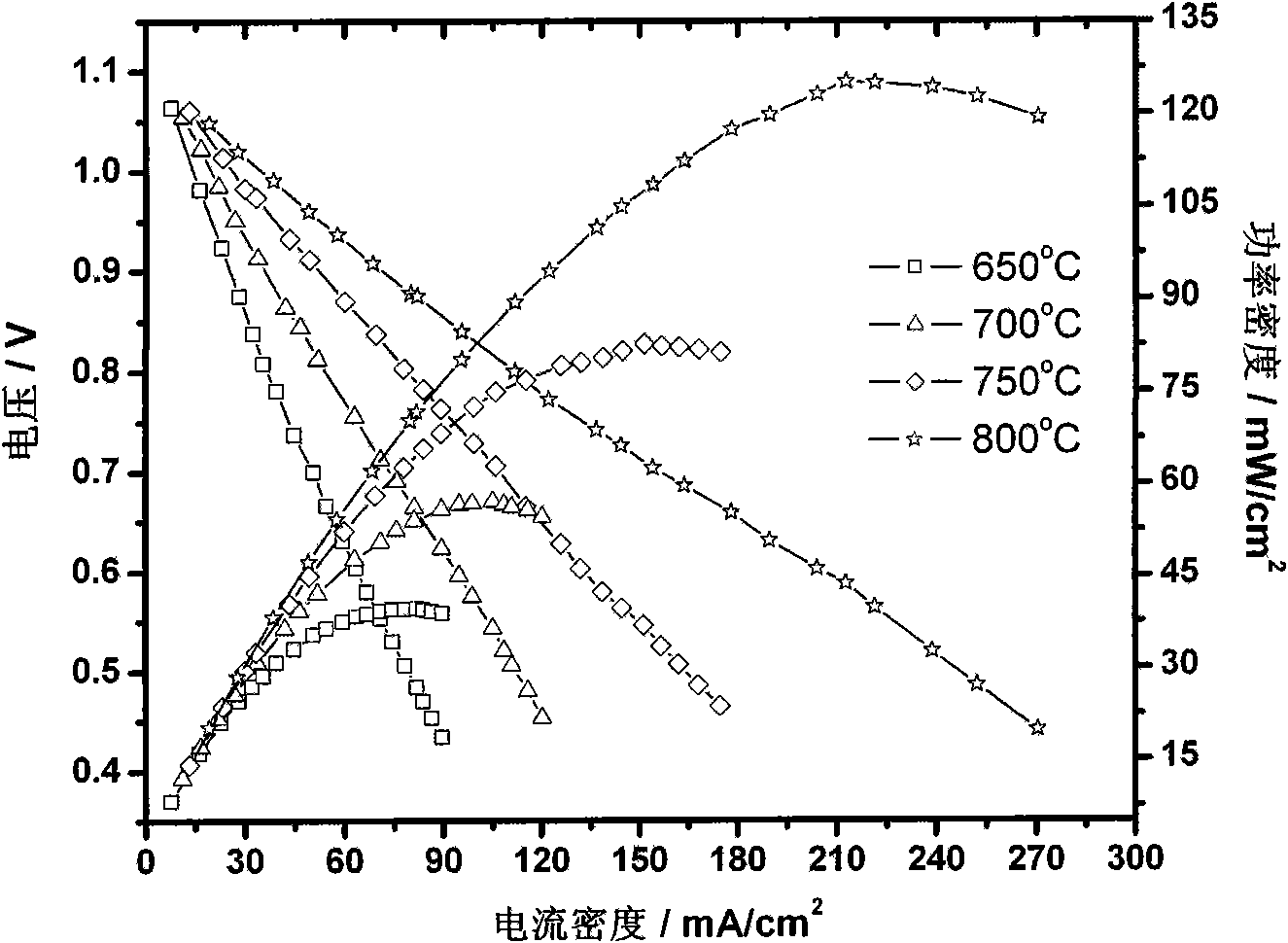

[0050] Example 3 Charcoal + cerium oxide direct carbon fuel cell as fuel

[0051] On the basis of embodiment 2, increase the cathode layer for electricity collection, that is, the structure is: a tubular solid oxide fuel cell of NiO-YSZ / NiO-SSZ / SSZ / LSM-SSZ / LSM, and then change the carbon black fuel into charcoal+ Cerium oxide was used as fuel for power generation test. Its electrical properties are as attached Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com