Manufacturing method of liquid crystal alignment layer

A technology of liquid crystal alignment layer and manufacturing method, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems that cannot be completely solved, the surface state of rubbed fabric is difficult to control, and the pretilt angle of liquid crystal molecules is inconsistent and other problems, to avoid rubbing foreign matter and mura, to avoid poor display characteristics, and to shorten production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

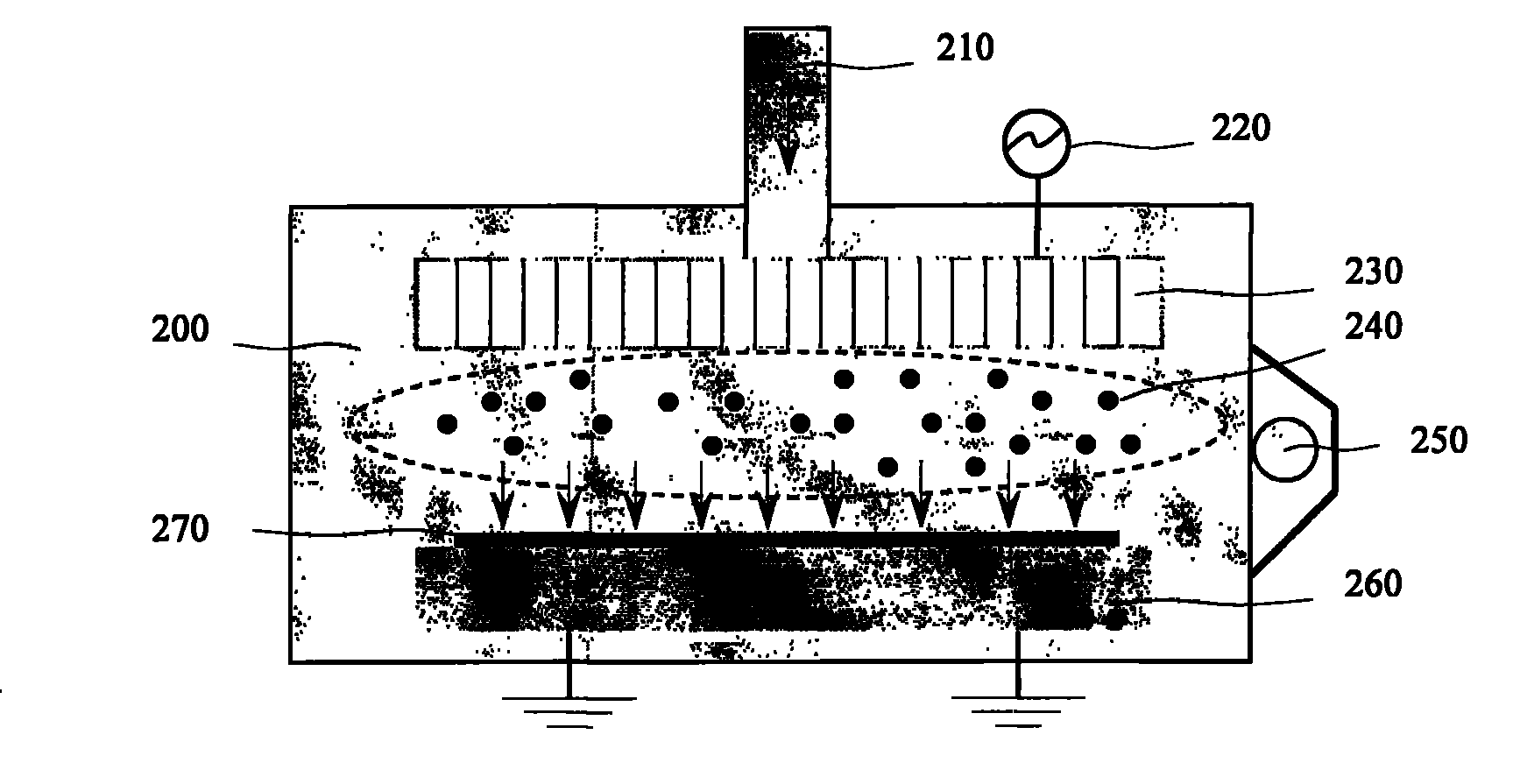

[0098] In this embodiment, the degree of vacuum in the deposition chamber 200 is 10 -6 Torr, the glass substrate is heated from 270 to 300 °C, H 2 The flow rate is 50sccm, CH 4 The flow rate is 0.2sccm, the power of the high-frequency negative voltage 220 is 5MHz, and the gas pressure is 50×10 2 Pa; the distance between the ion gun 510 and the glass substrate 270 is 10 cm, the relative angle 530 to the glass substrate 270 is 40°, and the skew angle 540 is 3°.

[0099] Such as Figure 10 Shown, the preparation method of liquid crystal alignment layer of the present invention comprises the following steps:

[0100] (a1) A deposition chamber 200 is provided, a base 260 is provided on the anode side of the deposition chamber 200, a glass substrate 270 is provided on the base 260, and a gas distributor 230 is provided on the cathode side;

[0101] (a2) evacuate the deposition chamber 200 to a vacuum state through the exhaust hole 250 on the deposition chamber 200, and its vacuu...

Embodiment 2

[0107] In this embodiment, the degree of vacuum in the deposition chamber 200 is 10 -7 Torr, the glass substrate is heated from 270 to 450 °C, H 2 The flow rate is 500sccm, CH 4 The flow rate is 10sccm, the power of the high-frequency negative voltage 220 is 20MHz, and the gas pressure is 500×10 2 Pa; the distance between the ion gun 510 and the glass substrate 270 is 25 cm, the relative angle 530 to the glass substrate 270 is 45°, and the skew angle 540 is 7°.

[0108] The preparation method of the liquid crystal alignment layer of the present invention comprises the following steps:

[0109] (b1) Set up a deposition chamber 200, a base 260 is provided on the anode side of the deposition chamber 200, a glass substrate 270 is provided on the base 260, and a gas distributor 230 is provided on the cathode side;

[0110] (b2) The deposition chamber 200 is pumped to a vacuum state through the exhaust hole 250 on the deposition chamber 200, and its vacuum degree is 10 -7 Torr; ...

Embodiment 3

[0116] In this embodiment, the degree of vacuum in the deposition chamber 200 is 10 -6 Torr, the glass substrate is heated from 270 to 400 °C, H 2 The flow rate is 250sccm, CH 4 The flow rate is 5sccm, the power of the high-frequency negative voltage 220 is 10MHz, and the gas pressure is 100×10 2 Pa; the distance between the ion gun 510 and the glass substrate 270 is 20 cm, the relative angle 530 to the glass substrate 270 is 42.5°, and the skew angle 540 is 4°.

[0117] The preparation method of the liquid crystal alignment layer of the present invention comprises the following steps:

[0118] (c1) Set up a deposition chamber 200, a base 260 is provided on the anode side of the deposition chamber 200, a glass substrate 270 is provided on the base 260, and a gas distributor 230 is provided on the cathode side;

[0119] (c2) Evacuate the deposition chamber 200 to a vacuum state through the exhaust hole 250 on the deposition chamber 200, and its vacuum degree is 10 -6 Torr; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com