Geometrical structure of trolling nylon braided line and method for measuring mechanical property thereof

A technology of nylon weaving and geometric structure, applied in the testing of machine/structural components, using stable tension/pressure to test the strength of materials, measuring force, etc., can solve the problems of affecting growth and development, slow death, waste of fishery resources, etc. , to make up for the deficiencies of the standard system and to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

[0010] Trolling nylon braided line is generally braided by 8 nylon monofilaments.

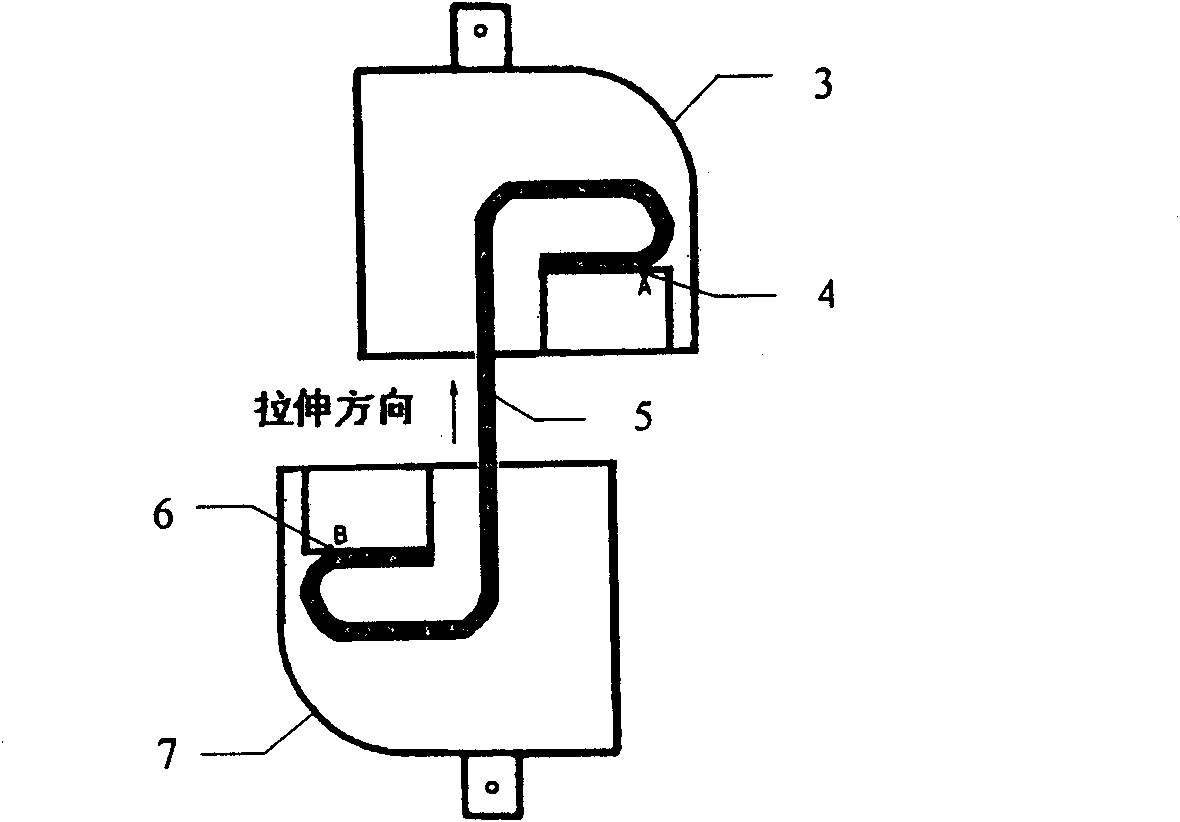

[0011] figure 1 3 and 7 respectively represent the upper and lower clamps of the INSTRON 4466 strength testing machine pneumatic ring clamp, figure 1 4 and 6 respectively represent the upper clamping point A and the lower clamping point B of the upper clamp of INSTRON 4466 strength testing machine and the trolling nylon braided line sample, figure 1 5 in the trolling fishing nylon braided line sample, figure 1 The distance from the upper clamping point A to the lower clamping point B represents the clamping distance (1.20m) during the test of the trolling nylon braided line sample.

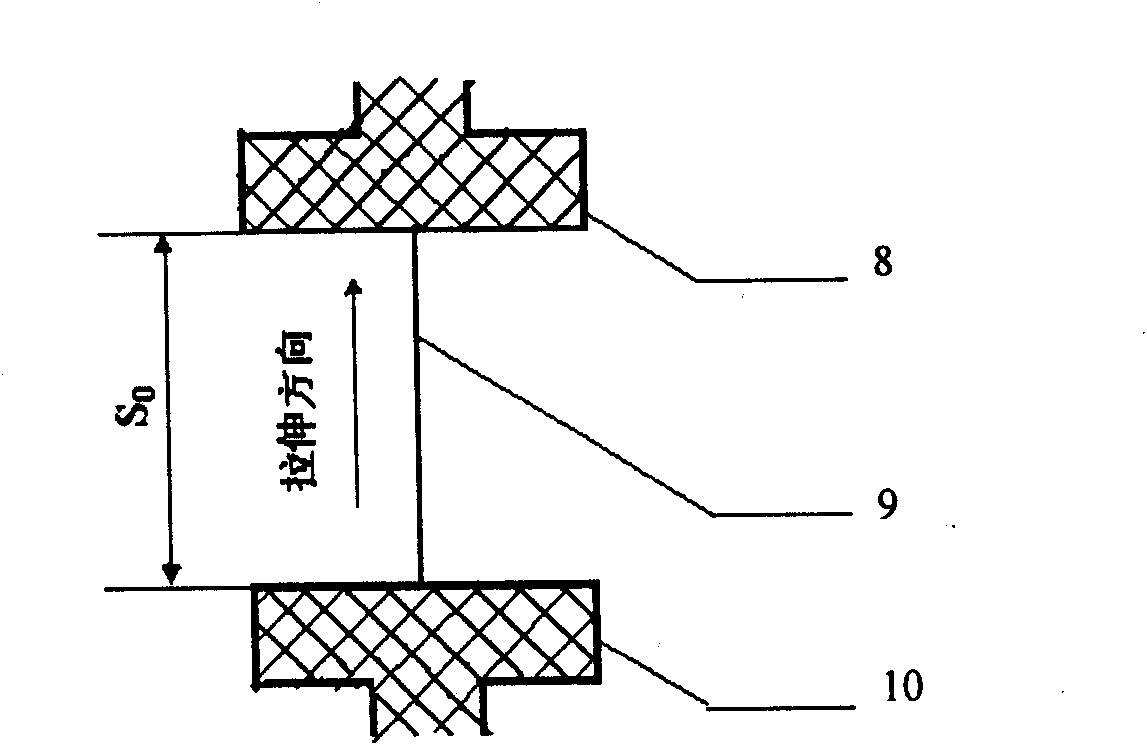

[0012] figure 2 8 and 10 in the figure represent the upper and lower clamps of the pneumatic flat clamps of the INSTRON 4466 strength testing machine, respectively. figure 2 The 9 in i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com