Improved structure of dyeing machine

A printing and dyeing machine and unit technology, applied in textile processing machine accessories, textiles and papermaking, textile material processing, etc., can solve problems such as belt loss of elasticity, affecting the quality of printing and dyeing products, and inability to print and dye transmission at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in combination with specific embodiments.

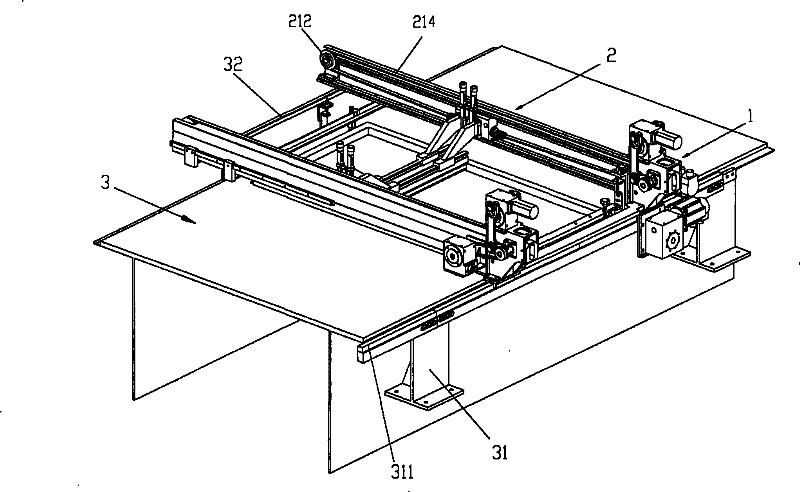

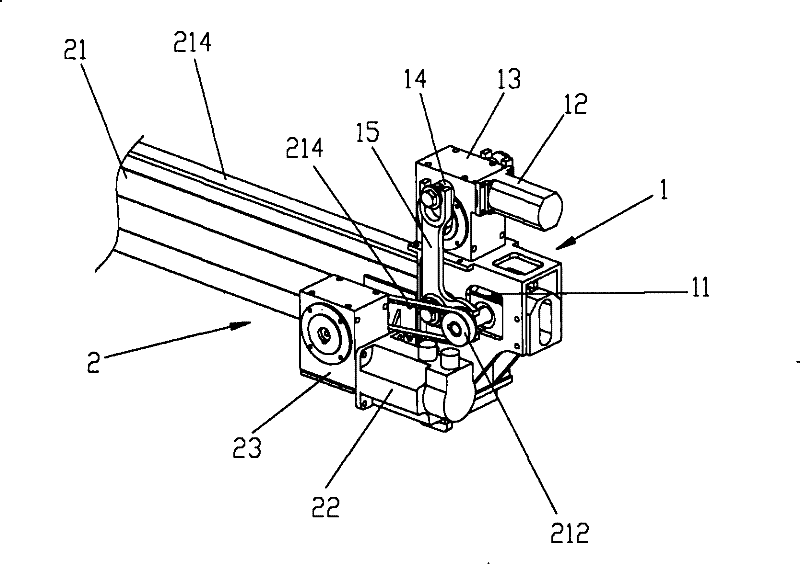

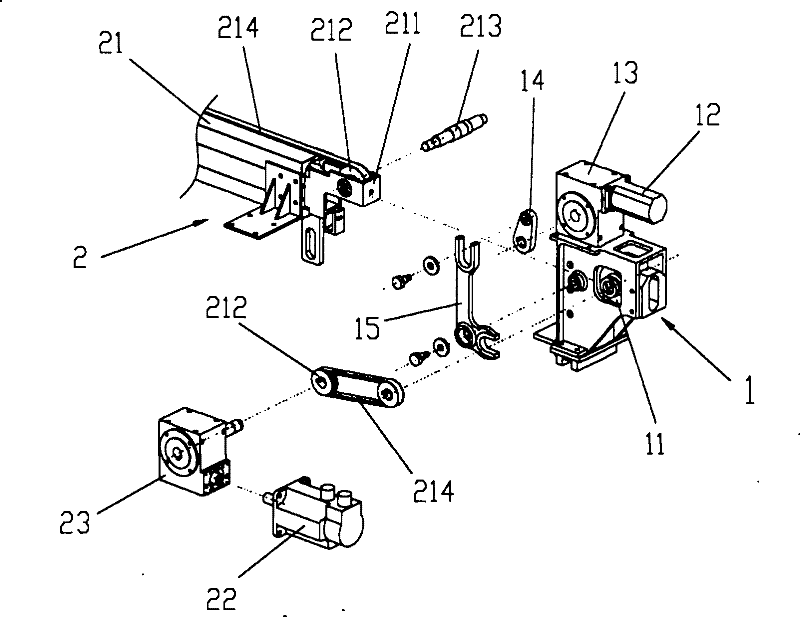

[0013] As shown in Figures 1 to 5, the structure of the printing and dyeing machine provided by the present invention mainly includes:

[0014] A lifting unit 1, the lifting unit 1 is provided with a lifting slot 11:

[0015] A lifting motor 12, the motor 12 is mounted on the lifting unit 1 and connected to the reducer 13;

[0016] A speed reducer 13, and a swing rod 14 protrudes from both sides of the speed reducer 13;

[0017] A swing lever arm 15, the swing lever arm 15 is pivotally arranged on the elevator unit 1, one end is connected to the swing lever 14, and the other end is inserted into the transmission rod 214 of the printing and dyeing track 21;

[0018] A printing and dyeing unit 2, the printing and dyeing unit 2 is provided with a printing and dyeing track 21;

[0019] A printing and dyeing track 21, one end of the printing and dyeing track 21 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com