Pressure reducing and injection increasing agent used for flooding well and preparation method thereof

A technology of injection enhancer and industrial product, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in establishing an effective driving system, deviation of fluid seepage laws, and increasing difficulty in reservoir development, and achieve the The effect of microbial growth, improving seepage capacity, and increasing water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The parts by weight of each component of the pressure-reducing injection-increasing agent for water injection wells are:

[0050] 1. Lauric acid monoethanolamide (Amel CME) (industrial product): 31 parts;

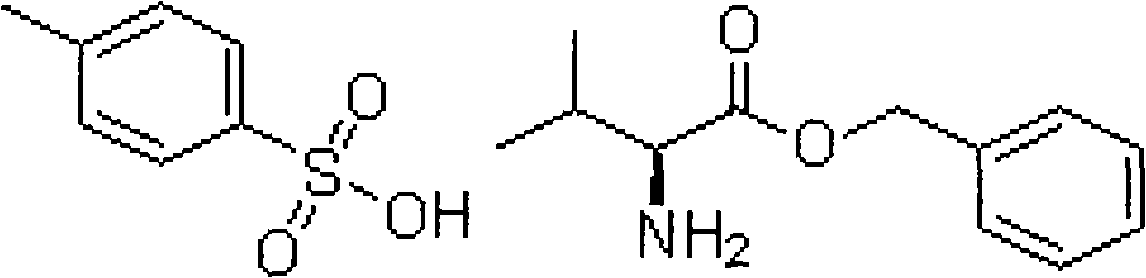

[0051] 2. L-valine benzyl ester p-toluenesulfonate: 4.3 parts;

[0052] 3. C 8-10 Alkyl glucoside: 5.7 parts;

[0053] 4. Sodium nitrite (industrial product); 0.7 parts;

[0054] 5. Vitamin A (industrial product): 0.7 parts;

[0055] 6. Fluorocarbon surfactant (FN-2): 0.06 parts;

[0056] 7. Methanol (industrial product): 28 parts;

[0057] 8. Water: 30.24 parts.

[0058] Preparation method: First, add Amer CME to the enamel reaction kettle in proportion, and slowly raise the temperature to 63°C; secondly, add 10% of the required amount of methanol under constant stirring; after continuing to stir for 30 minutes, add L -Valine benzyl ester p-toluenesulfonate, C 8-10 Alkyl glucoside, stir while adding, then add sodium nitrite, vitamin A, FN-2, and the remainin...

Embodiment 2

[0061] The preparation method of depressurization and injection increasing agent for water injection well is the same as that of Example 1, and the weight ratio of each component is:

[0062] 1. Lauric acid monoethanolamide (Amel CME) (industrial product): 33 parts;

[0063] 2. L-valine benzyl ester p-toluenesulfonate: 4 parts;

[0064] 3. C 8-10 Alkyl glucoside: 6.6 parts;

[0065] 4. Sodium nitrite (industrial product); 0.8 parts;

[0066] 5. Vitamin A (industrial product): 0.75 parts;

[0067] 6. Fluorocarbon surfactant (FN-2): 0.07 parts;

[0068] 7. Methanol (industrial product): 31 parts;

[0069] 8. Water: 30.24 parts.

[0070] Effect: In X-93 well, in the injection water distribution room, use a high-pressure pump to pump the depressurization and injection-increasing agent into the high-pressure pipeline according to the ratio of 0.12% of the water injected into the well, and inject it into the formation with the injected water, and the wellhead pressure drops fr...

Embodiment 3

[0072] The preparation method of depressurization and injection increasing agent for water injection well is the same as that of Example 1, and the weight ratio of each component is:

[0073] 1. Lauric acid monoethanolamide (Amel CME) (industrial product): 36 parts;

[0074] 2. L-valine benzyl ester p-toluenesulfonate: 3.5 parts;

[0075] 3. C 8-10 Alkyl glucoside: 6.8 parts;

[0076] 4. Sodium nitrite (industrial product); 0.9 parts;

[0077] 5. Vitamin A (industrial product): 0.8 parts;

[0078] 6. Fluorocarbon surfactant (FN-2): 0.07 parts;

[0079] 7. Methanol (industrial product): 31 parts;

[0080] 8. Water: 29.93 parts.

[0081] Effect: In Well X-56, a high-pressure pump is used to pump the pressure-reducing injection-increasing agent into the high-pressure pipeline according to the proportion of 0.15% of the water injected into the water distribution room of the injected water. to 22.4MPa, a decrease of 12.84 percentage points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com