Drive shaft screw thread on-vehicle restoration special tool

A special tool and drive shaft technology, applied in the direction of manufacturing tools, metal processing equipment, tangent devices, etc., can solve the problem of no drive shaft thread special tool, etc., and achieve the effect of simple structure, light weight and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

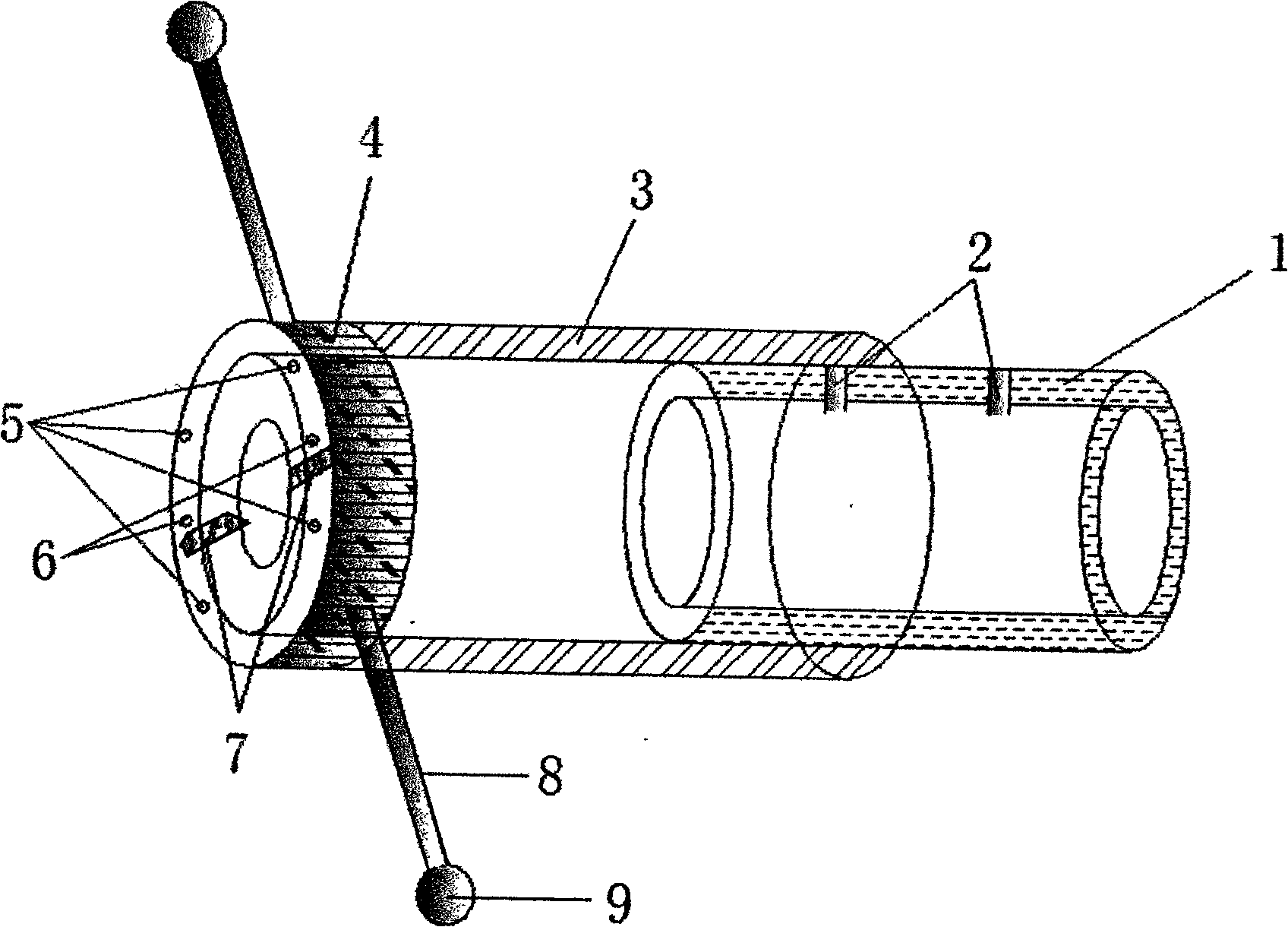

[0012] exist figure 1 Among them, a special tool for repairing the thread of the drive shaft on the car, which consists of an inner threaded sleeve 1, a positioning screw 2, an outer threaded sleeve 3, a tool holder plate 4, a connecting screw 5, a jacking screw 6, a turning tool 7, a screw rod 8, plastic The ball 9 is composed of two positioning screws 2 in the middle of the inner threaded sleeve 1, the outer threaded sleeve 3 is connected and fixed with the tool holder plate 4 with the connecting screw 5, and the turning tool 7 is fixed on the tool holder plate 4 with the top fixing screw 6 , be provided with screw rod hole at the center position of knife holder disc 4, after passing screw rod hole with screw rod 8 strings, the plastic ball 9 that threaded connection is housed at its two ends.

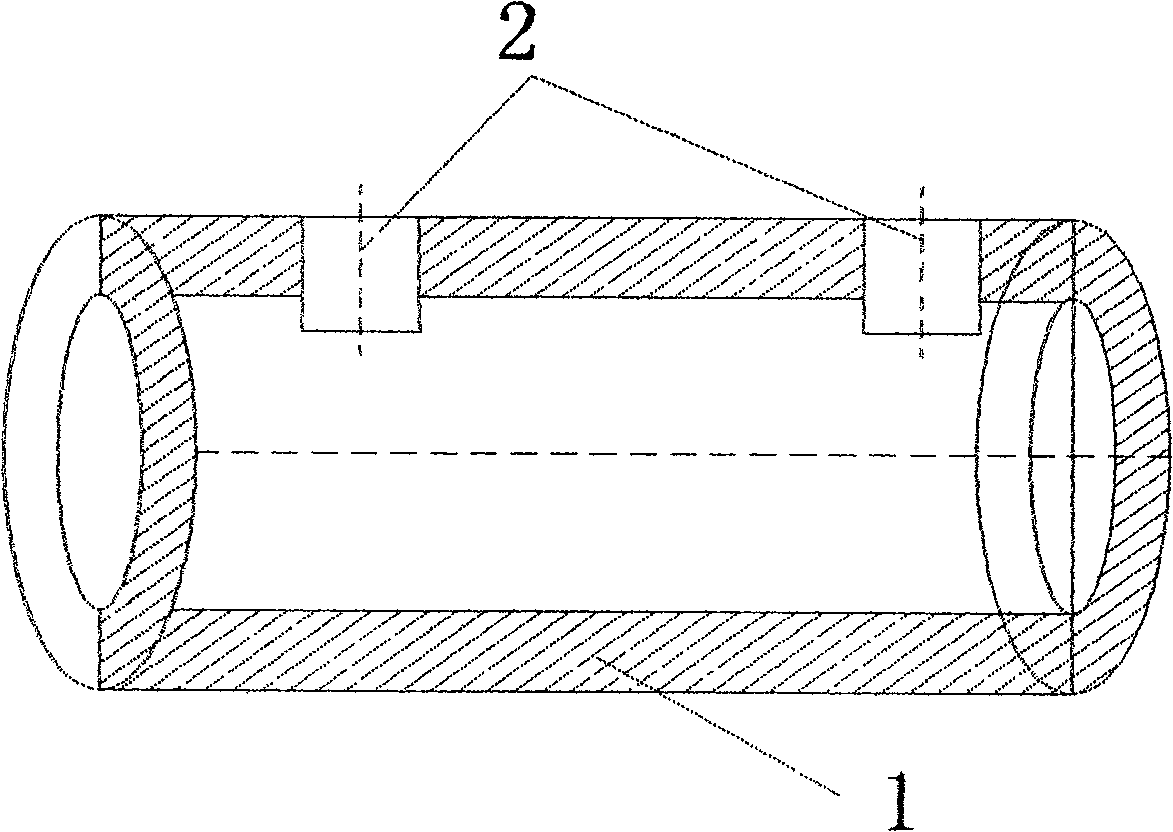

[0013] exist figure 2 Among them, two positioning screws 2 are arranged in the middle of the inner threaded sleeve 1 .

[0014] exist image 3 Among them, two connecting screws 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com