Power divider and application method thereof

An application method and power splitter technology, which is applied to waveguide devices, electrical components, connecting devices, etc., can solve problems affecting firmness, affecting antenna third-order intermodulation, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

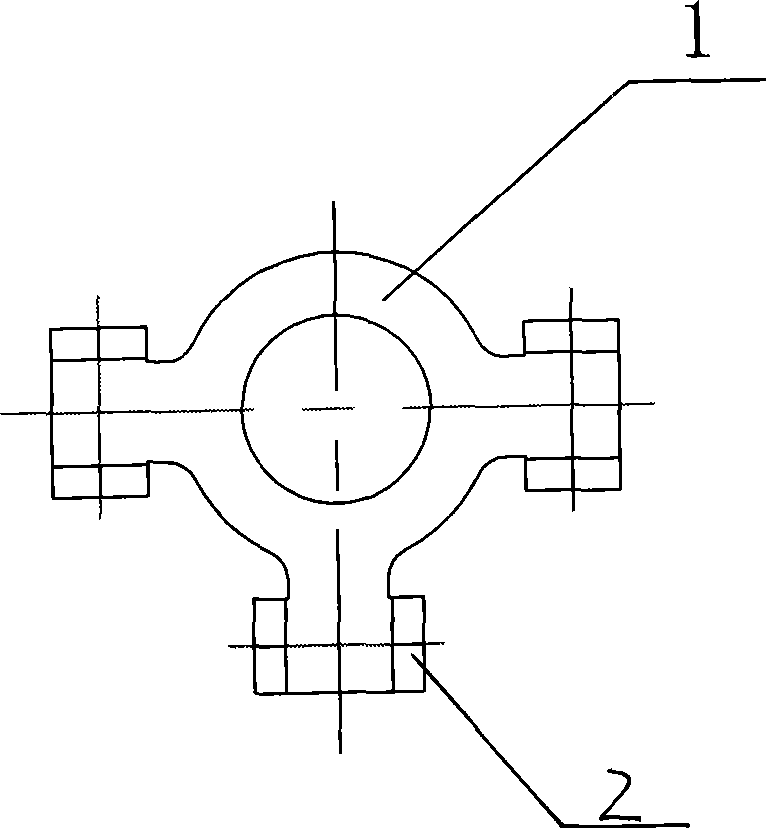

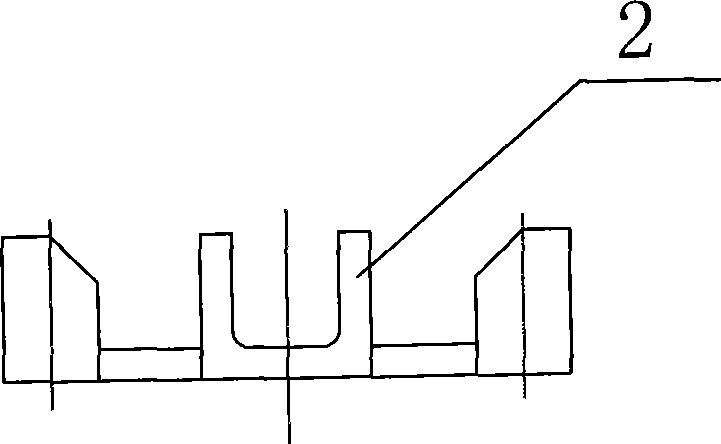

[0009] Such as figure 1 , 2 As shown, the power divider body 1 of the power divider is of a sheet-like ring shape, and three antennae 2 are distributed equidistantly on the outer edge of the ring. Each antenna is U-shaped, and the antenna 2 is used to fix the cable, and the cable is welded and fixed with the same material. Then expose the inner conductor of the end of the fixed cable suspended on the power divider body 1, and weld the cable inner conductors fixed by the three antennae together in the air. The welding point is exactly in the hollow part of the power divider ring to ensure This facilitates the welding of the inner conductor of the cable, and also ensures that the inner and outer conductors are not connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com