Solid electrolytic capacitor

A technology of solid electrolysis and capacitors, which is applied in the direction of electrolytic capacitors, capacitors, capacitor electrodes, etc., can solve the problems of increased cost and decreased material utilization rate, and achieve the effects of simplified manufacturing process, excellent material utilization rate, and increased manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

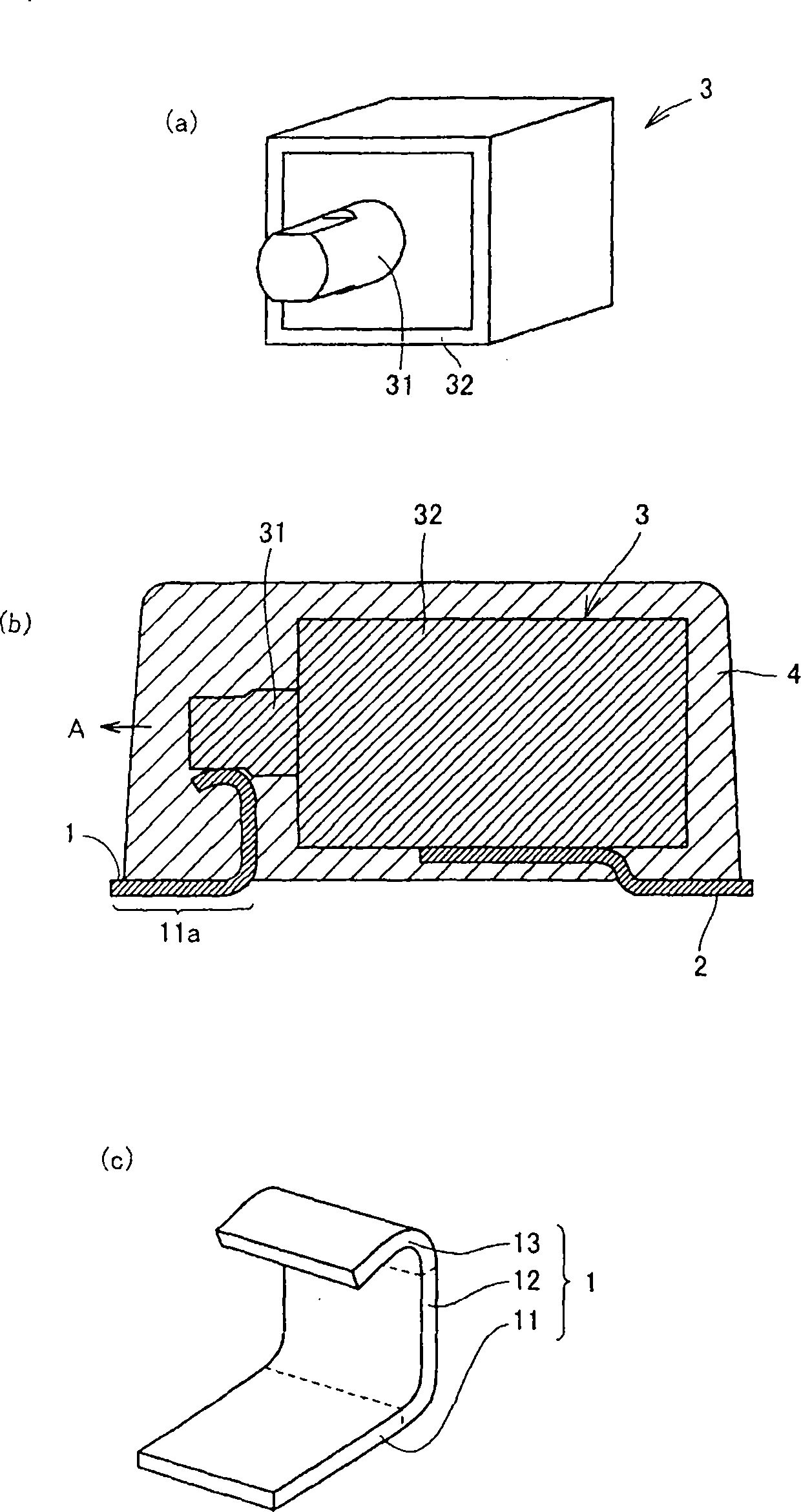

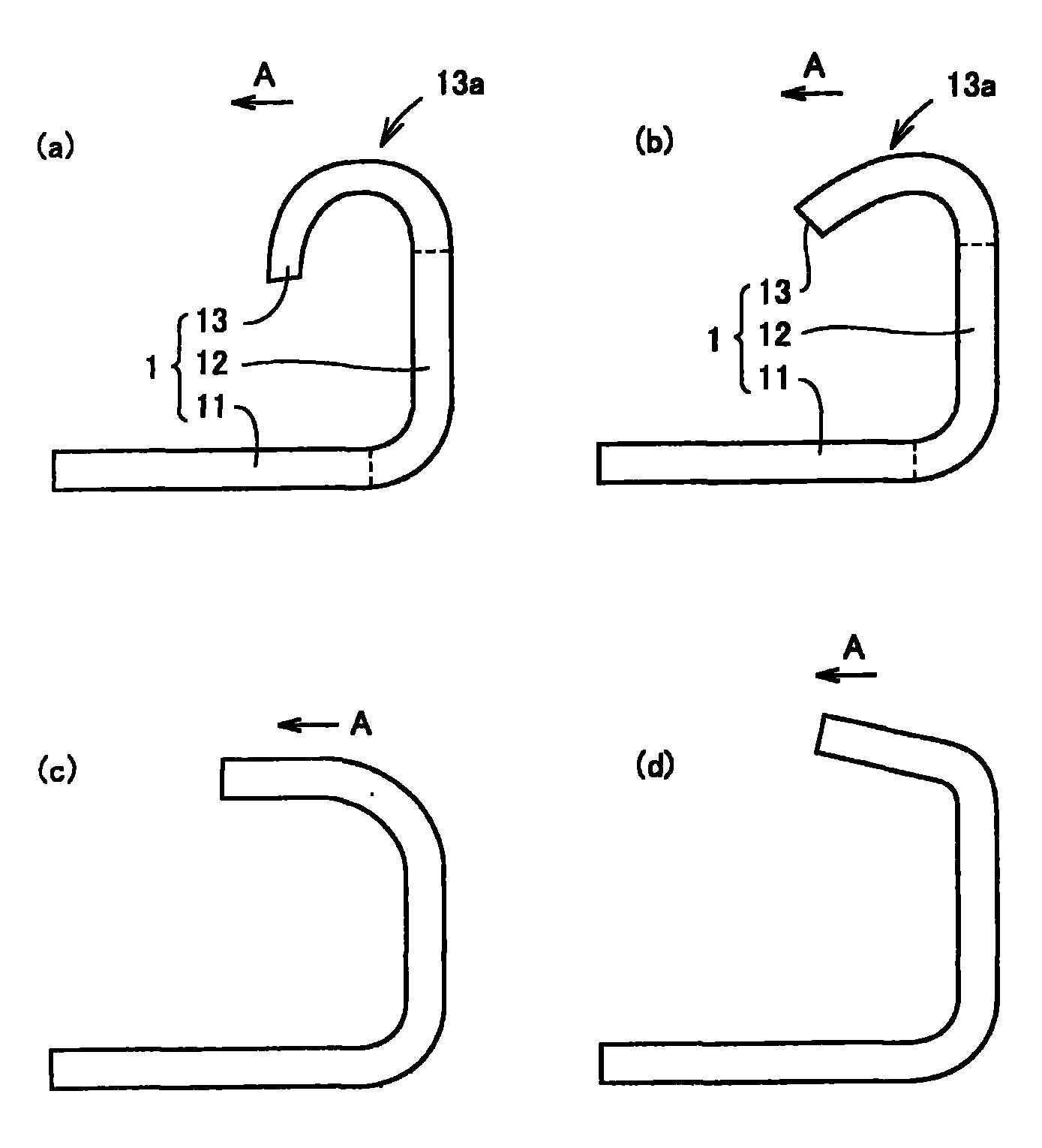

[0018] figure 1 The structure of the solid electrolytic capacitor of this embodiment is illustrated. figure 1 (a) is a perspective view of the capacitor element 3 constituting the solid electrolytic capacitor. like figure 1 As shown in (a), the capacitor element 3 includes an anode lead-out portion 31 and a cathode lead-out portion 32 , and the anode lead-out portion 31 has a structure protruding from one end face of the capacitor element 3 . In this specification, a capacitor element refers to various solid electrolytic capacitor elements having a structure in which a valve metal is used as an anode, a dielectric film is formed on the surface of the anode metal, and a cathode is formed on the surface of the dielectric film. The solid electrolyte layer, and then the cathode extraction layer is formed on the surface of the solid electrolyte layer. figure 1 (b) is a cross-sectional view showing the structure of the solid electrolytic capacitor of the present embodiment. ...

no. 2 approach

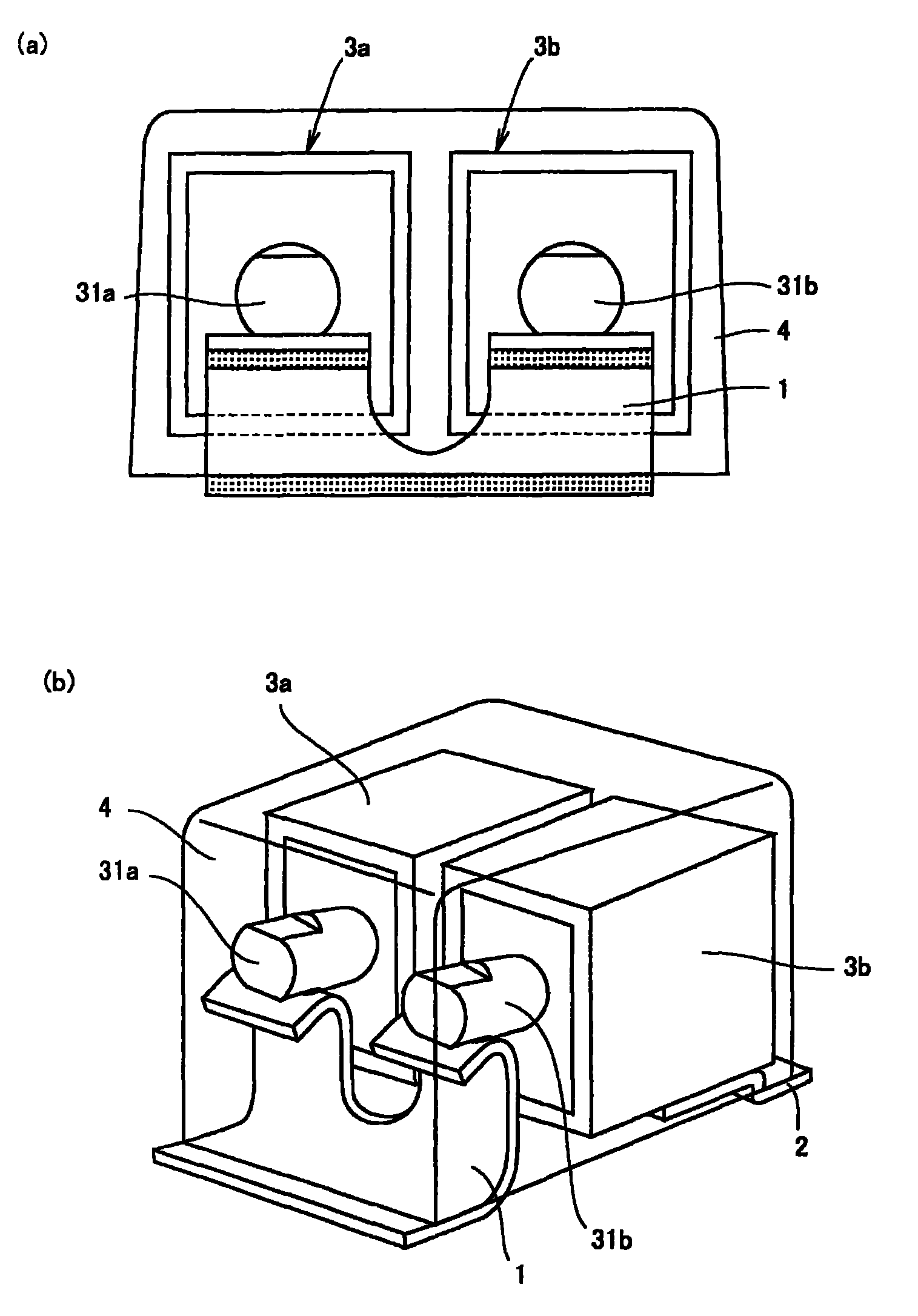

[0029] Image 6 The structure of the solid electrolytic capacitor of this embodiment is illustrated. Image 6 (a) is a side view of the solid electrolytic capacitor when viewed from the protruding direction of the anode lead-out portions 31a, 31b, Image 6 (b) is a perspective view. like Image 6 As shown in (a) of FIG. 2 , two capacitor elements 3 a and 3 b are provided, and the respective anode lead-out portions 31 a and 31 b are connected to one anode lead frame 1 . In this embodiment, unlike the first embodiment, the anode lead-out portions 31a and 31b are cylindrical. In addition, in the present embodiment, the bent portion 13 of the anode lead frame 1 has a slit opened in a direction in which the anode lead-out portions 31a and 31b protrude from the capacitor elements 3a and 3b, and the anode lead-out portions 31a and 31b and the anode lead frame 1 are located in the slit. Seam 13b is connected. Therefore, the anode lead-out portions 31a and 31b are in line contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com