Lens module group

A lens module and lens technology, applied in the field of photography, can solve problems such as increased leakage of springs, and achieve the effect of reducing the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

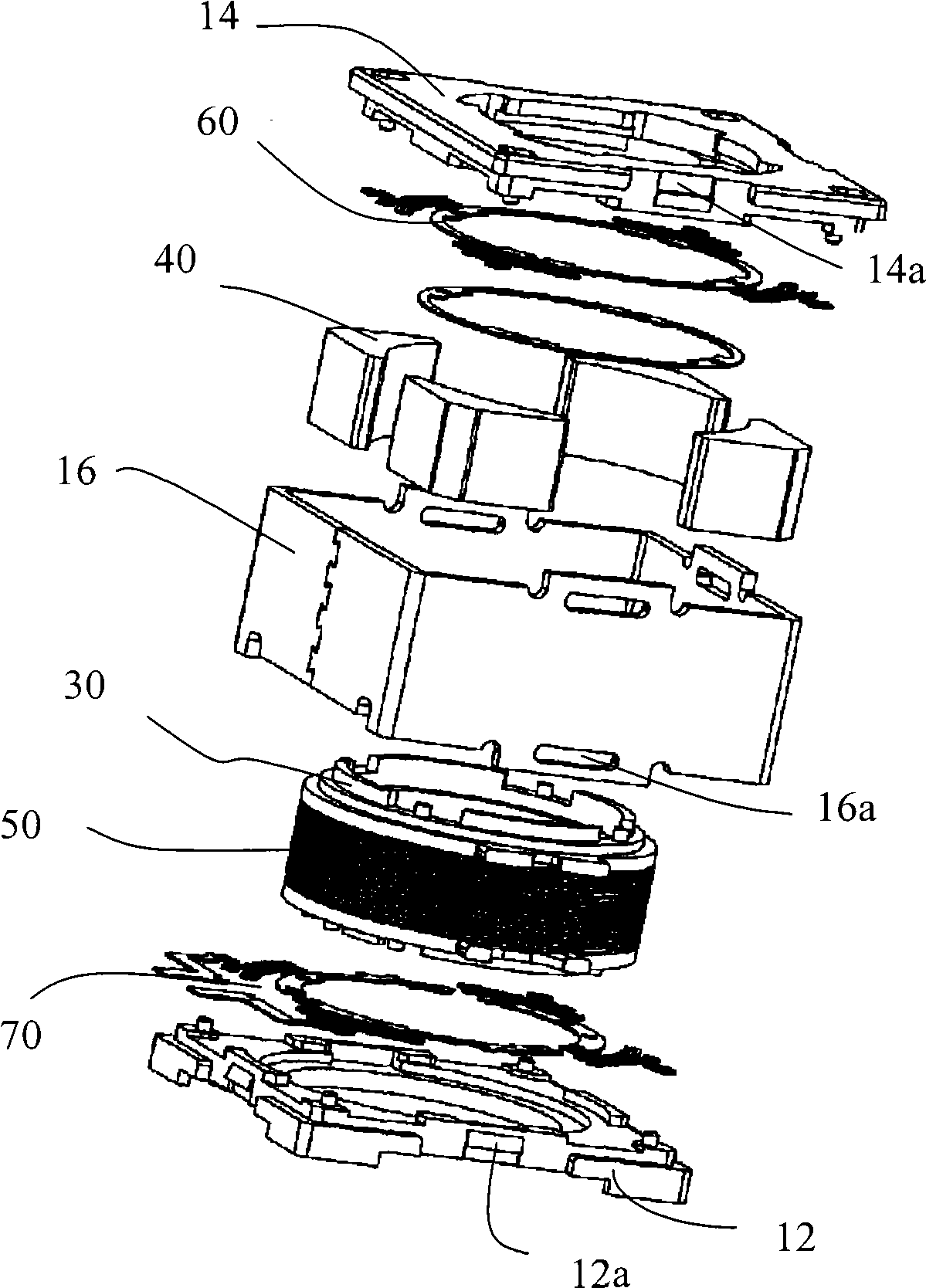

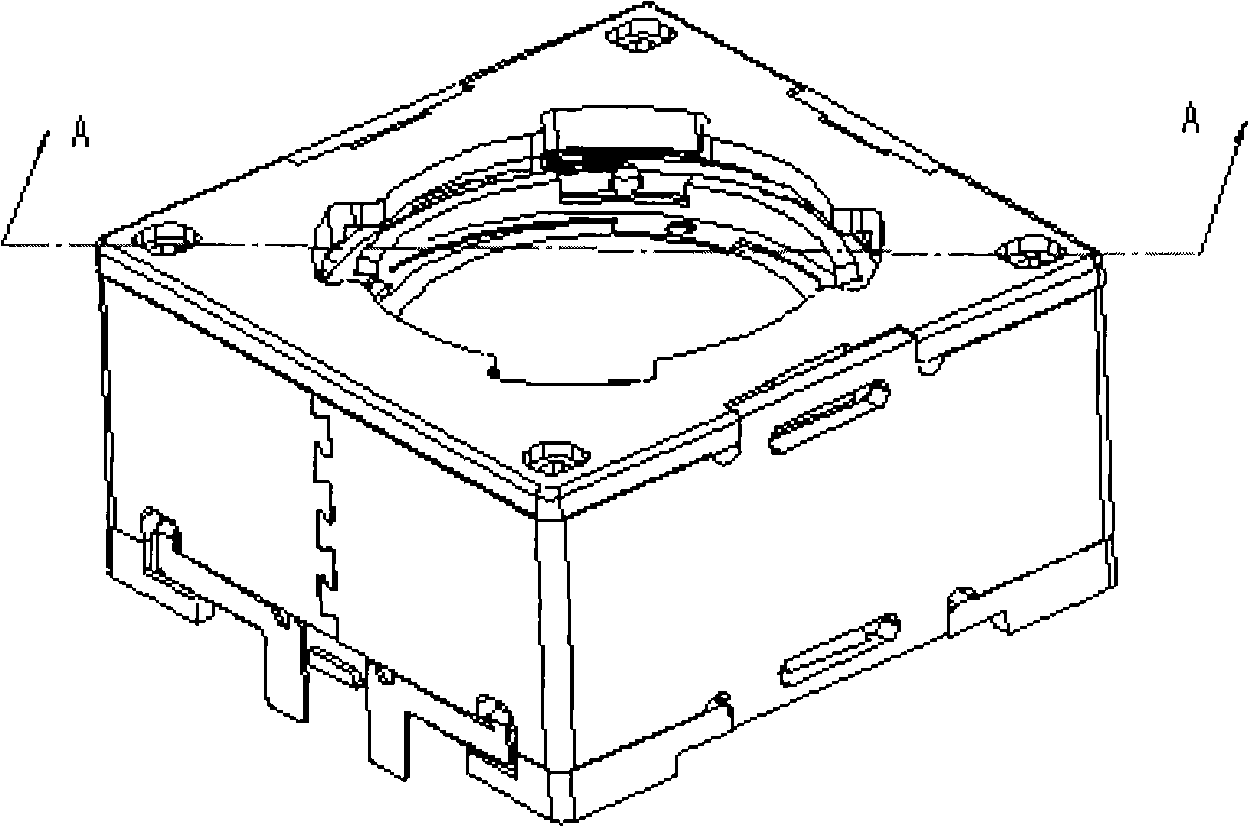

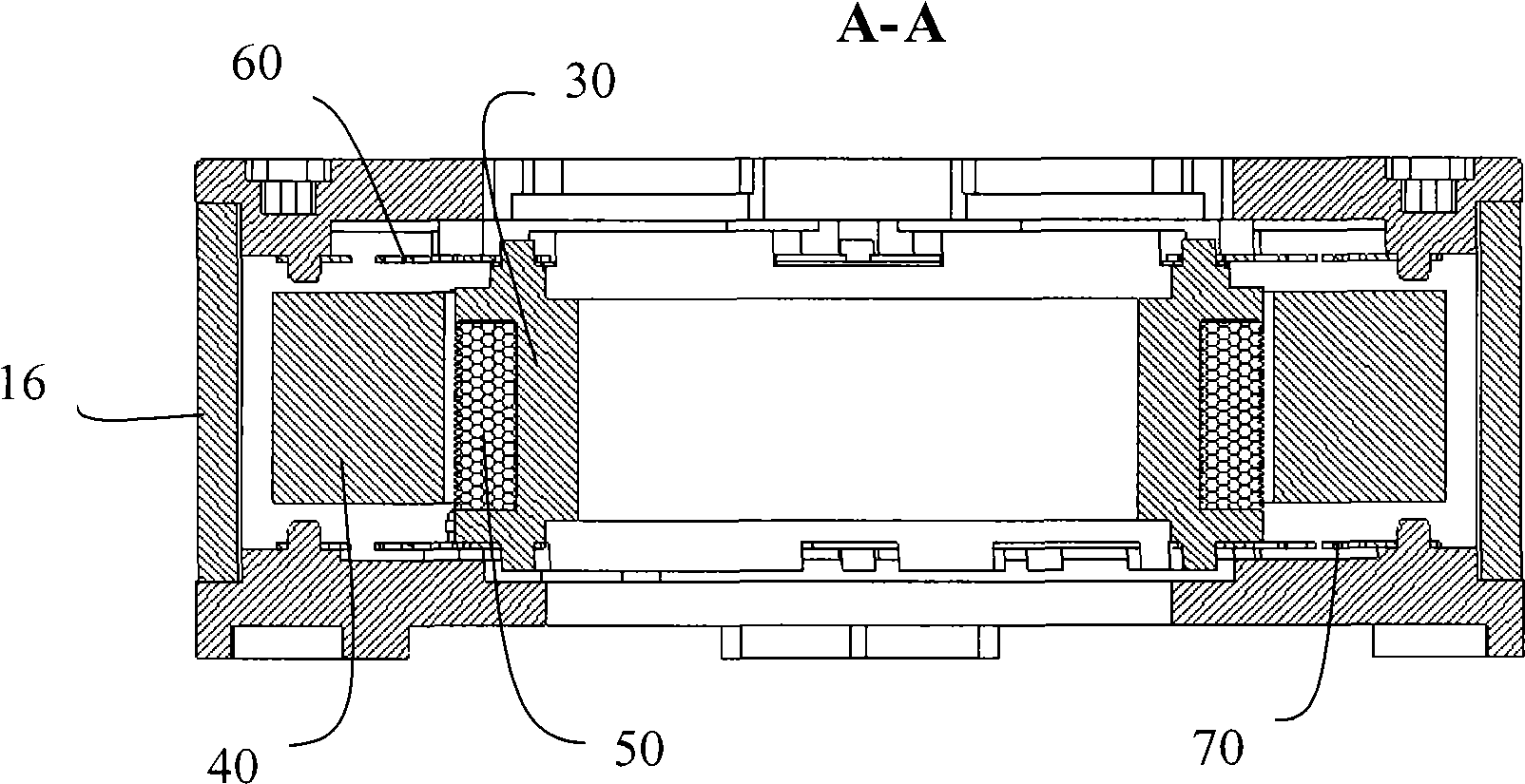

[0014] see Figure 1 to Figure 3 According to an embodiment of the present invention, the lens module includes a housing, a lens holder 30 installed in the housing for housing the lens, a magnet 40 fixed in the housing, a coil 50 wound on the lens holder 30, and A pair of leaf springs 60, 70 bias front and rear.

[0015] The housing includes a base 12, a cover 14, and an iron shell 16 connected between the base 12 and the cover 14. The base 12 and the cover 14 are respectively provided with several clasps 12a, 14a. The iron shell 16 is provided with a plurality of buckle holes 16 a to be buckled with the clasps 12 a and 14 a respectively, so as to fix the iron shell 16 between the base 12 and the cover 14 . The iron shell 16 is square, and there are four magnets 40 , which are respectively fixed on the four corners of the iron shell 16 . Each magnet 40 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com