Anti-scalding welding clamp

An electric welding tongs and anti-scalding technology, applied in the field of electric welding tongs, can solve the problems of electric leakage danger, heat insulation performance to be further improved, and unreliable installation structure, etc., so as to avoid fragmentation, improve anti-scalding and heat insulation performance, and reduce temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

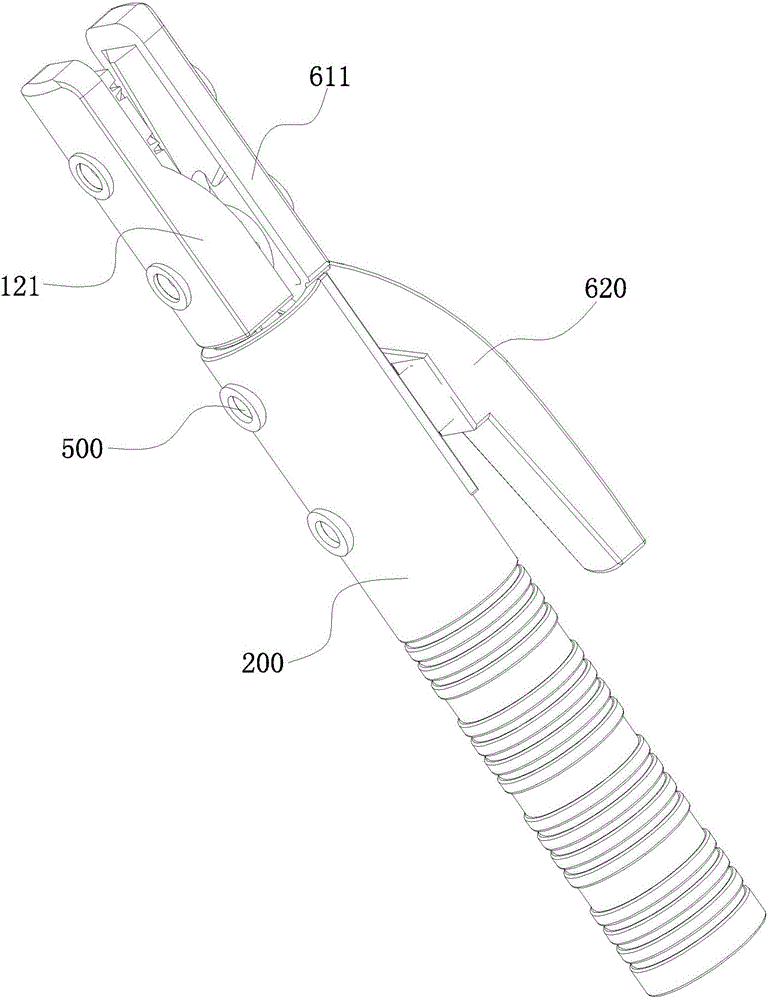

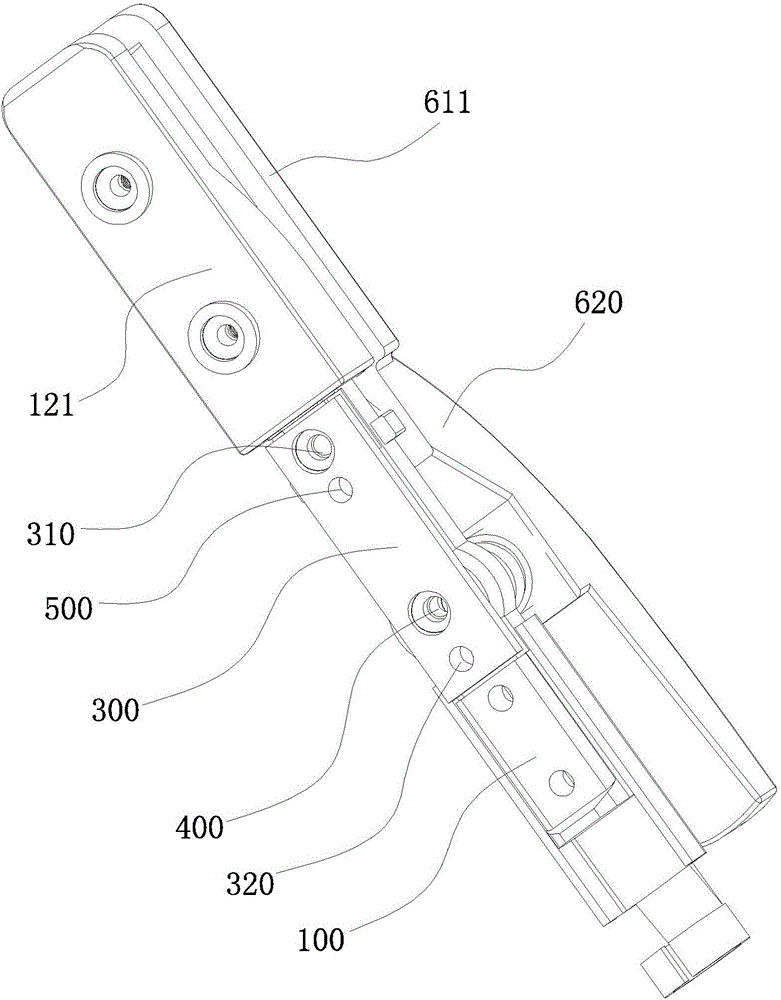

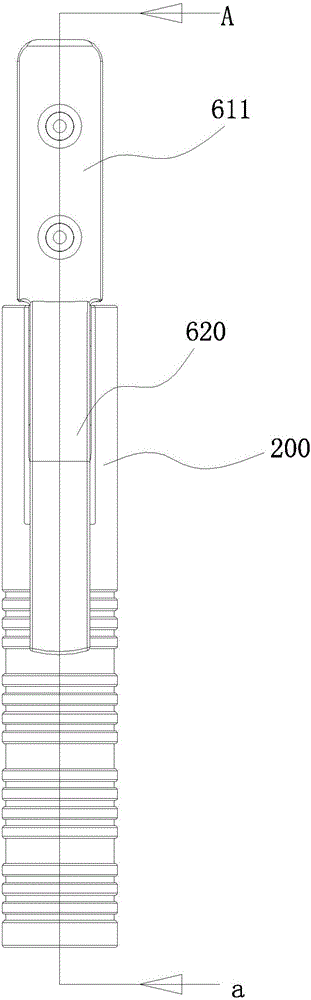

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an anti-scalding electric welding tongs includes: a conductor 100, an insulating handle 200, an insulating and heat-insulating pad 300, a pad connecting screw 400 and a handle connecting screw 500, which have the function of anti-scalding and heat insulation.

[0036] Since the traditional electric welding tongs do not have the insulation block 300, the insulating handle 200 is directly placed on the end of the conductor 100, so when the conductor 100 heats up continuously, the heat will be continuously transferred to the insulating handle 200. In this case, Can burn the user.

[0037] And the current electric welding tongs with anti-scalding function is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com