Metallic heat exchanger tube

A heat exchange tube, metal technology, applied in heat exchange equipment, tubular elements, heat transfer modification and other directions, can solve the problem of not being able to fully increase bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

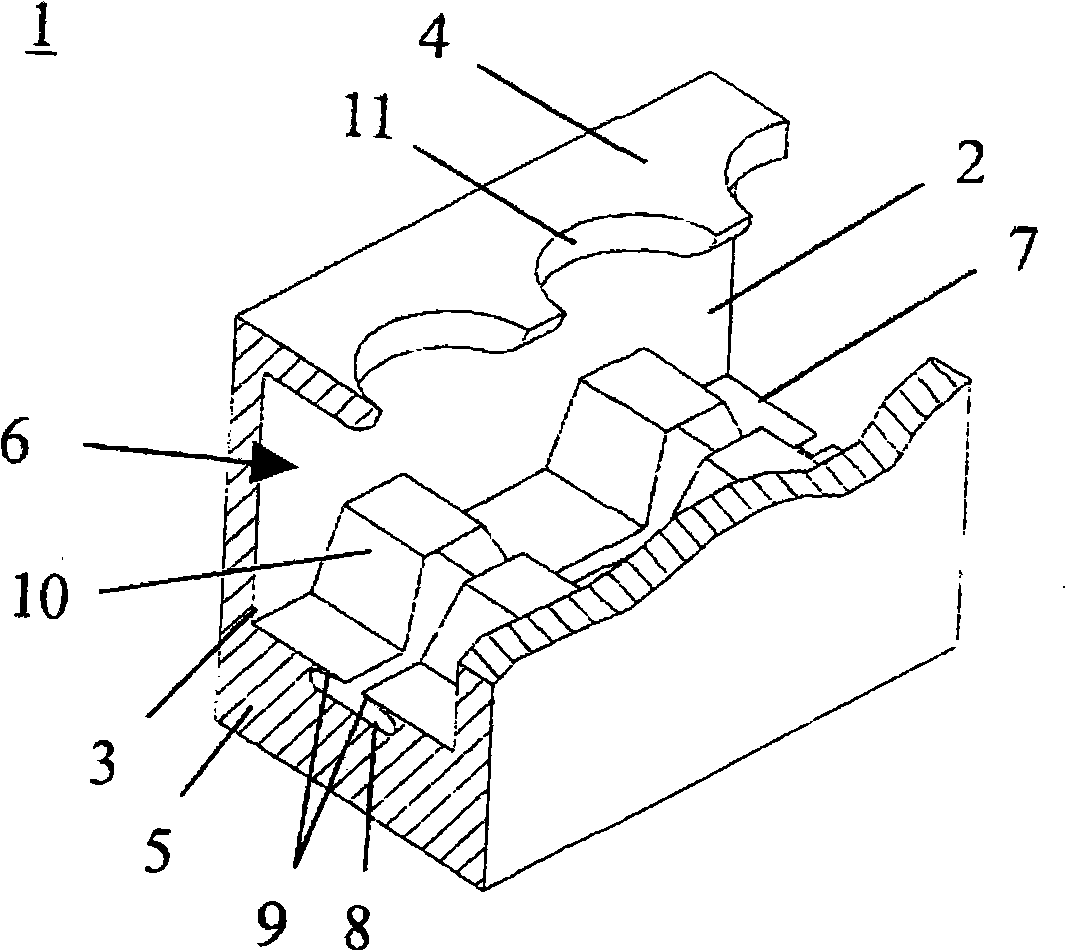

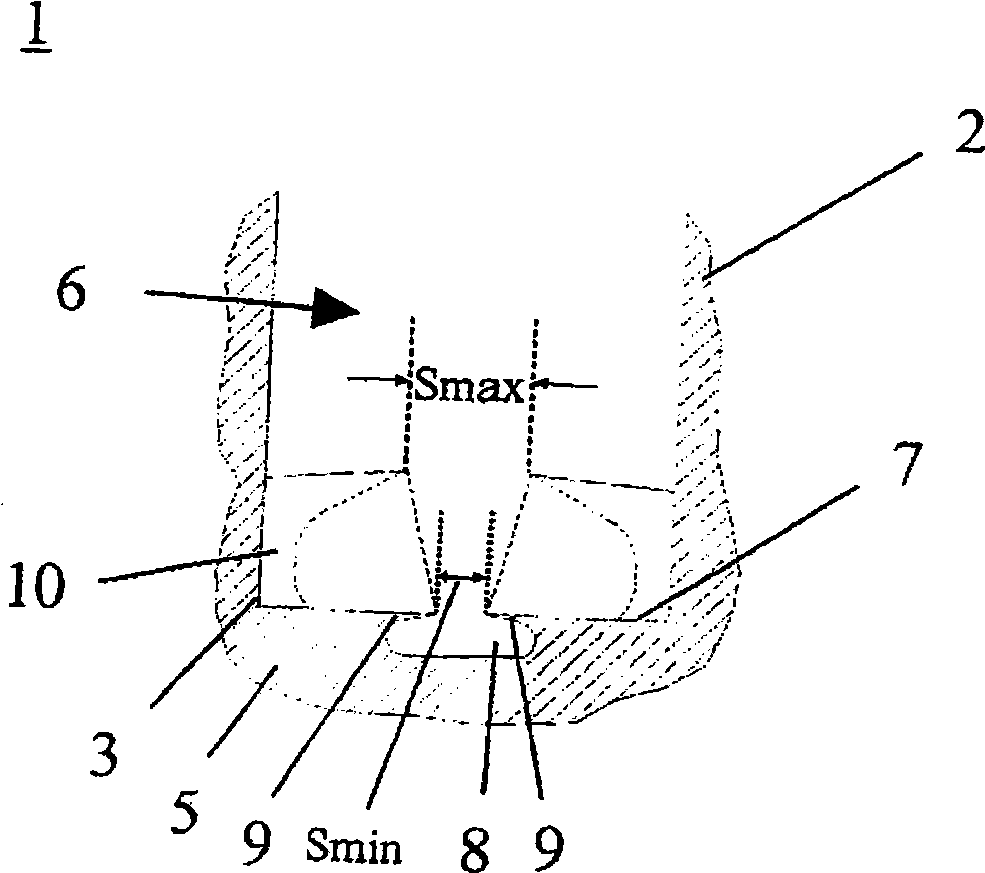

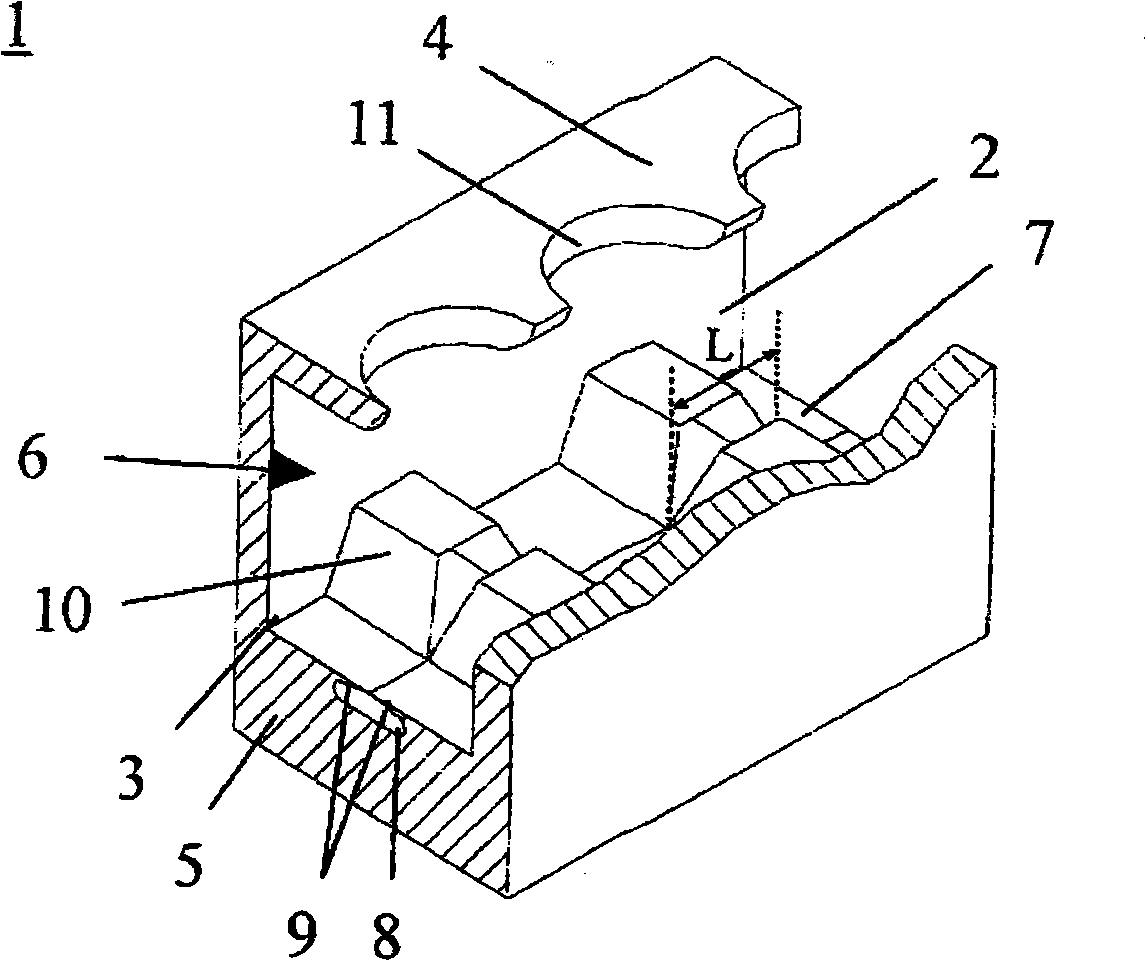

[0042] figure 1A view of the outside of a length of pipe of the present invention is shown. The integrally rolled ribbed tube 1 has ribs 2 running helically on the outside of the tube, between which initial grooves 6 are formed. The struts 2 extend continuously outside the tube along the delay line without interruption. The rib base 3 protrudes substantially radially from the tube wall 5 . The proposed rib tube 1 forms a recessed secondary groove 8 in the region of the groove bottom 7 where the primary groove 6 extends between two adjacent ribs 2 . The secondary groove 8 is delimited with respect to the primary groove 6 by a pair of mutually opposite material protrusions 9 formed of the material of the adjacent bead base 3 . The material protrusions 9 extend continuously along the initial groove 6, wherein a space S is formed between opposing material protrusions 9, which changes at a prescribed interval. When changing the cross-section of the secondary groove 8, the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com