Parallel type thermal differential evaporation cold (hot) water machine

An evaporative cooling and parallel technology, which is applied in the direction of evaporator/condenser, refrigerator, compressor with multiple evaporators, etc. Ice and other problems, to achieve the effect of improving energy efficiency ratio, facilitating maintenance, and increasing the average evaporating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

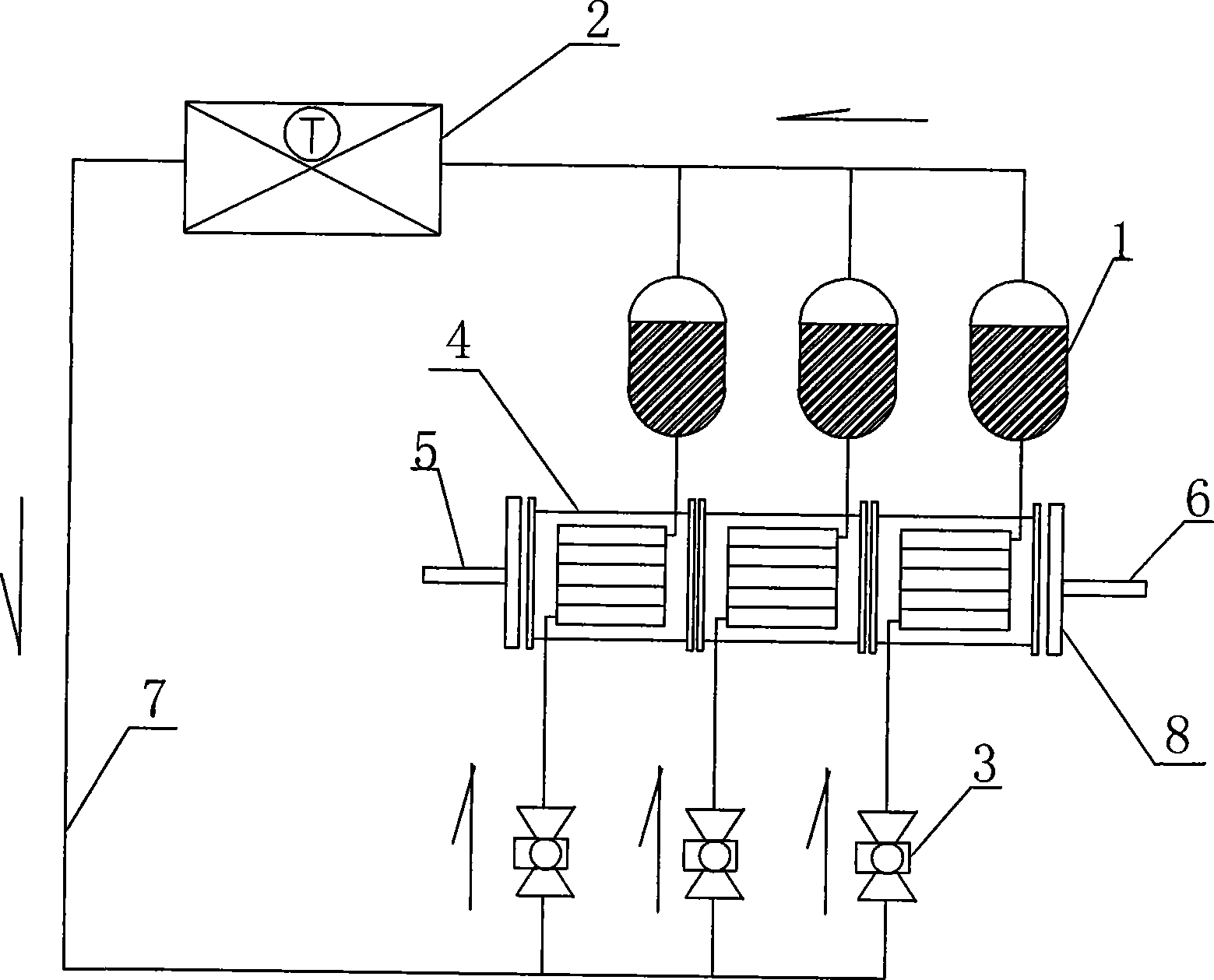

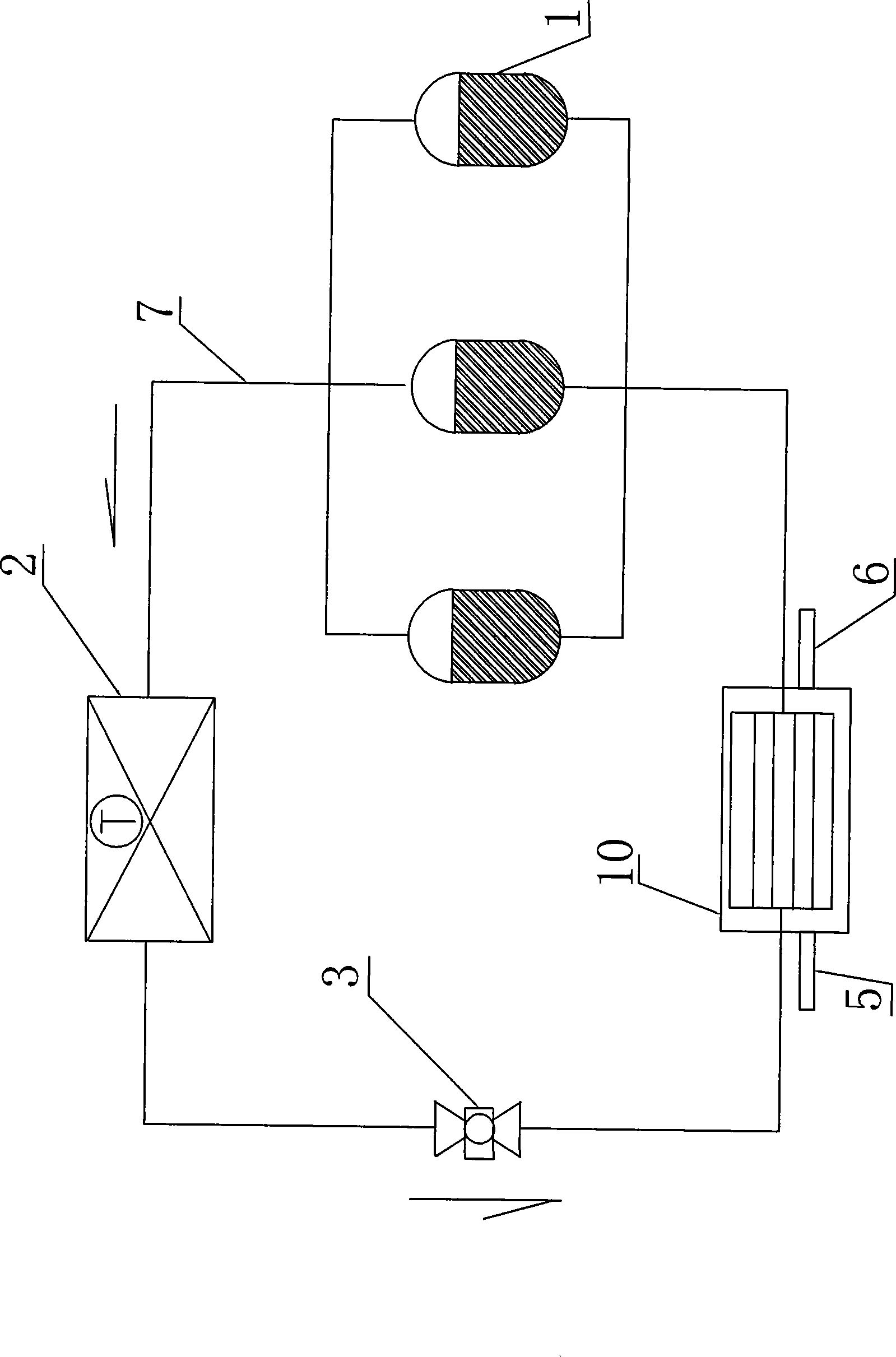

[0013] Such as figure 1 As shown, the present invention includes a condenser 2, two or more than two compressors 1, an evaporator cold water inlet pipe 5, an evaporator cold water outlet pipe 6, a refrigerant pipe 7, an evaporation unit 8 having the same number as the compressor, and The number of throttle valves 3 is the same as that of the compressors. A compressor, an evaporation unit and a throttle valve are sequentially connected to form a unit. Multiple units are arranged in parallel and then connected in series with a condenser to form a circulation system.

[0014] A plurality of evaporating units are connected in series along the water flow direction to form an evaporator, and the cold water outlet of the previous evaporating unit is connected to the cold water inlet of the following evaporating unit, so that the evaporators 8 are connected in series to form a series combination. The evaporator cold water inlet pipe 5 is connected from one side of the evaporator, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com