Superhigh-temperature heat pump drying system

A drying system and warming technology, applied in drying, dryer, drying of solid materials, etc., can solve problems such as difficulty in promotion, and achieve the effect of high air supply temperature and fully improved evaporation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

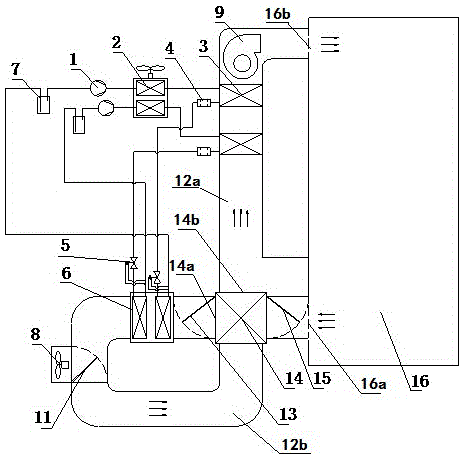

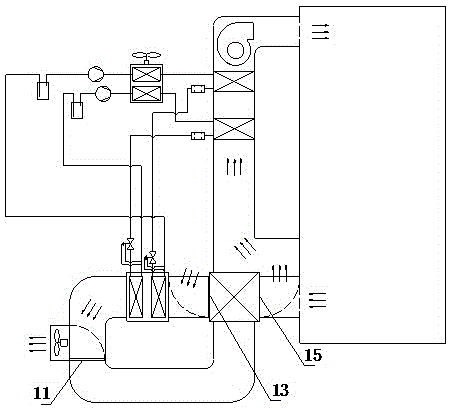

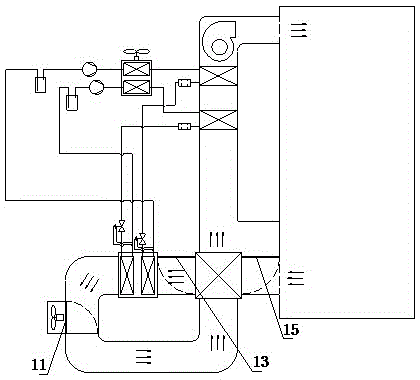

[0017] refer to figure 1 The shown a kind of ultra-high temperature heat pump drying system comprises a drying room 16, a return air channel 12a connected with the air supply port 16b and the return air port 16a of the drying room 16, the circulation fan 9 arranged in the return air channel 12a, and the return air channel 12a. The exhaust duct 12b connected to the air duct 12a, the exhaust fan 8 arranged at the passage opening of the exhaust duct 12b, the air heat recovery device 16 arranged at the intersection of the return air duct 12a and the exhaust duct 12b, and two sets of parallel use heat pump unit.

[0018] Each heat pump unit is composed of compressor 1, thermostat condenser 2, main condenser 3, expansion valve 5, evaporator 6, dry filter 4, gas-liquid separator 7 and other main refrigeration components connected in series through pipelines; Wherein, the main condenser 3 is placed in the return air passage 12a, and the evaporator 6 is placed in the exhaust air passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com