Leverage for reducing gear rack transmission backlash

A lever mechanism, rack and pinion technology, applied in the transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of increasing processing costs, installation costs, guarantees, etc., to reduce backlash and ensure reliability And safety, easy installation effect

Inactive Publication Date: 2010-12-01

HARBIN ENG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to manufacturing and installation errors, as well as to compensate for thermal deformation and provide space for storing lubricating oil, the rack and pinion meshing needs to leave a minimum backlash; the traditional method is to use double-plate gears to control the gap to reduce the rack and pinion meshing The method of empty return, this method of reducing empty return increases the processing cost and installation cost, and the double-plate gear must be adjusted regularly according to the usage; another common method is to design and process the gear shaft of the installed gear as an eccentric shaft, through The relative position of the gear and the rack is controlled to control the backlash, thereby effectively reducing backlash, but the structure of the eccentric shaft is difficult to ensure its mutual position for a long time under variable load conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

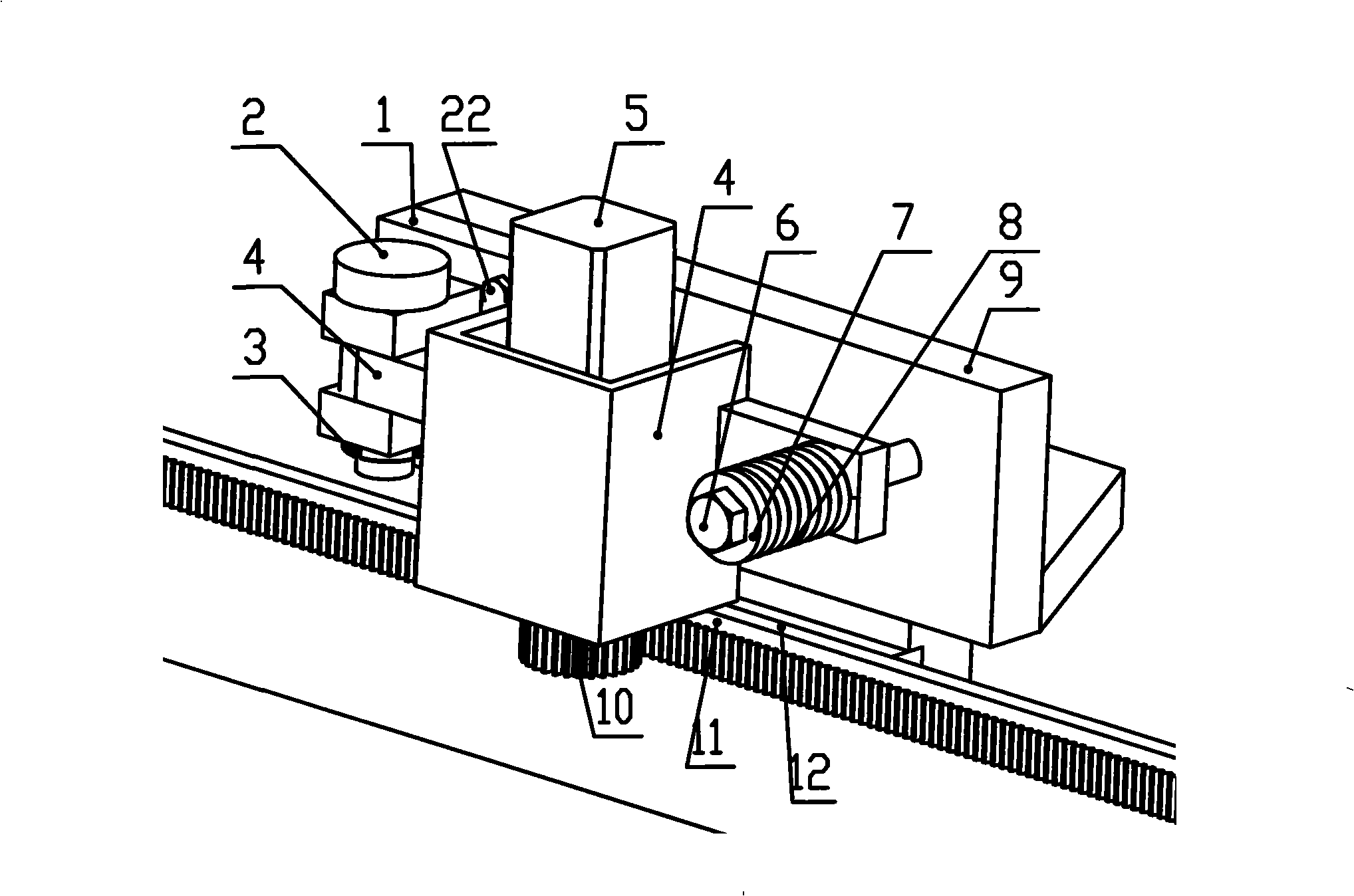

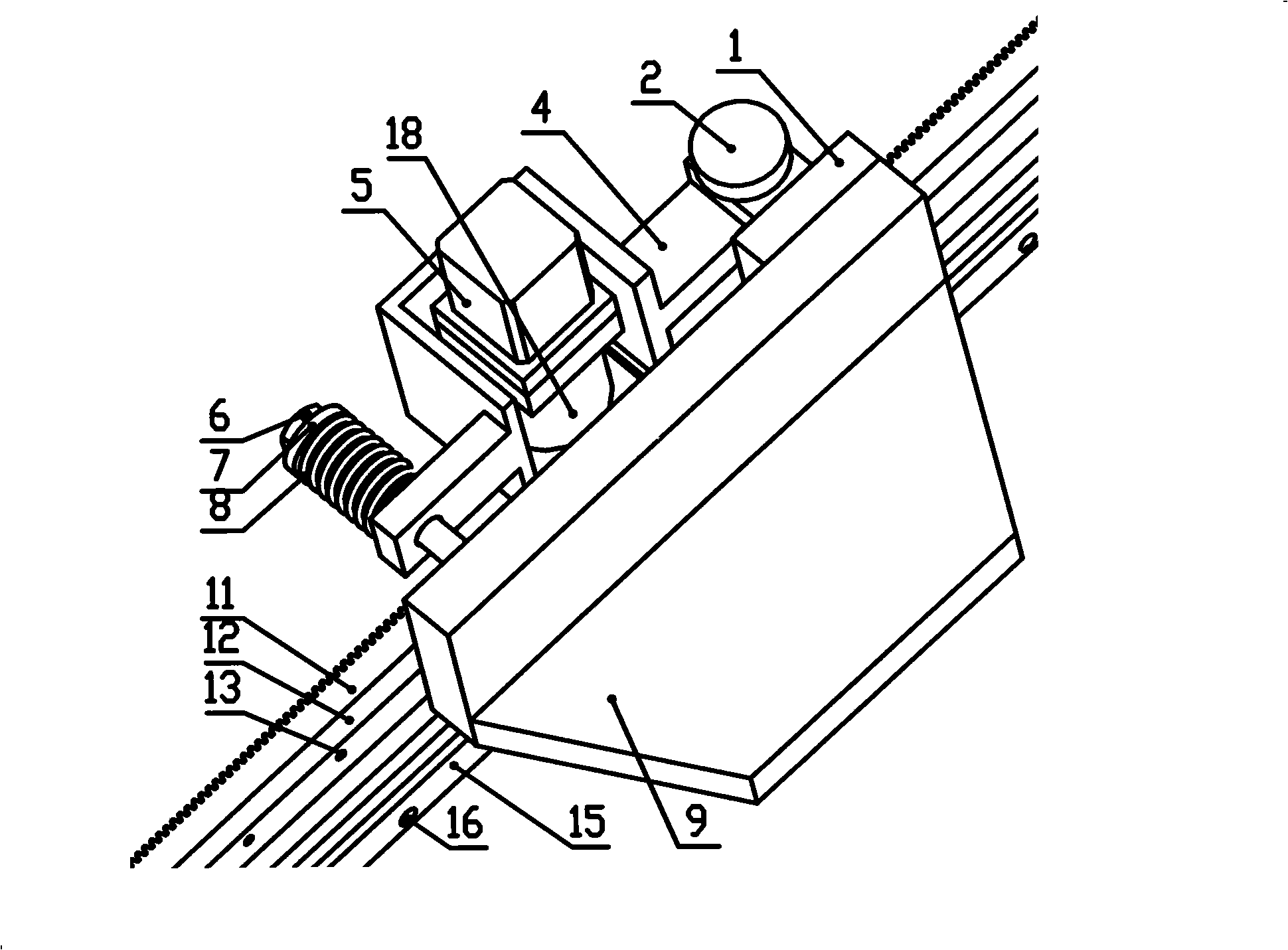

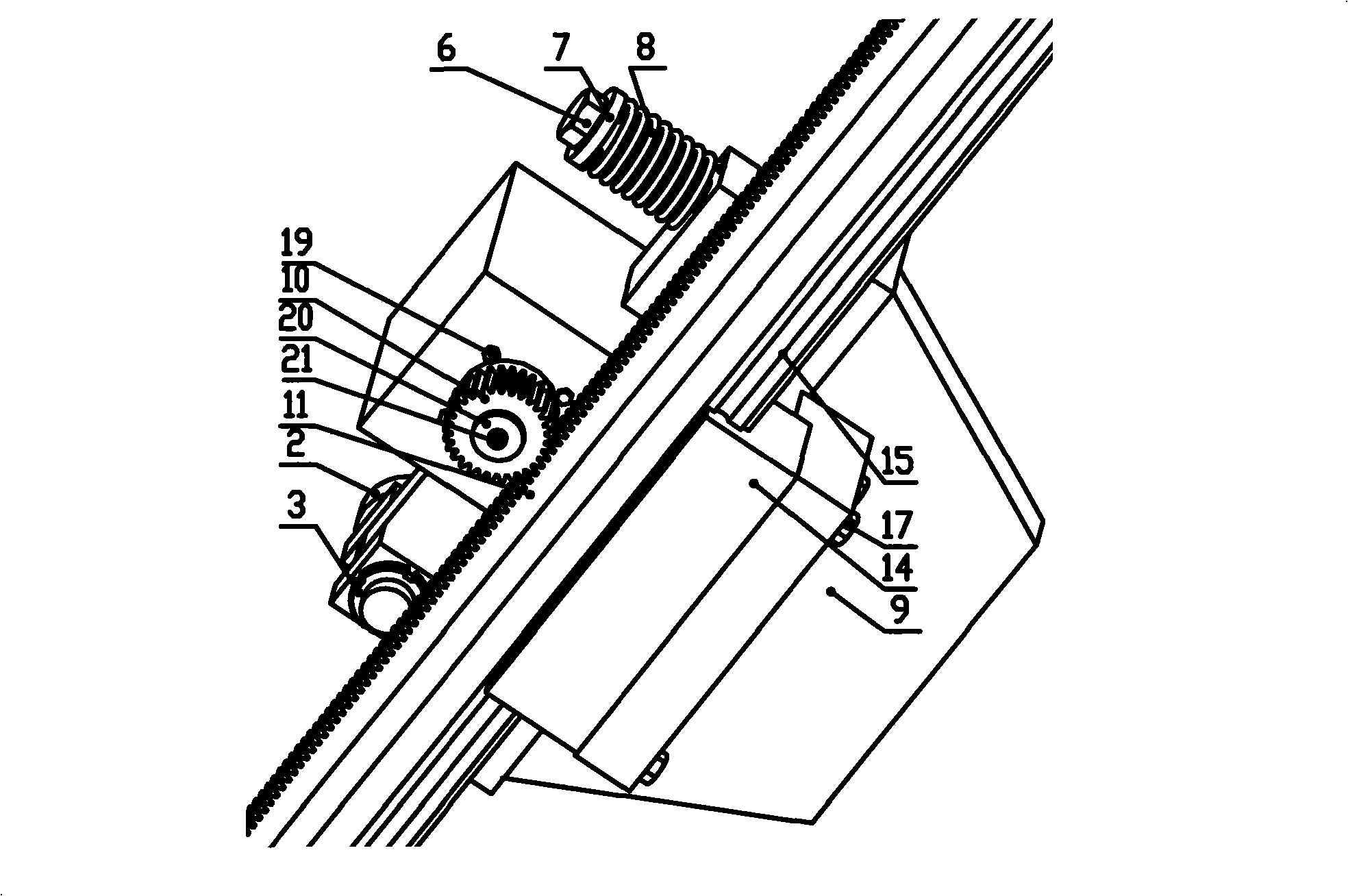

The invention provides leverage for reducing gear rack transmission backlash, comprising a rack, a gear, a gear transmission motor and a reducer. The invention is characterized in that a lever bracket is fixedly arranged on a moving body; one end of a lever is installed on the lever bracket via a plug; the gear is installed on an output shaft of the reducer which is installed in the middle part of the lever; the gear transmission motor is connected with the reducer; a through hole is arranged on the other end of the lever; screws are arranged in the through hole in series; a lever compressionspring is sheathed on the screw and the lever is fixed on the moving body. The lever is arranged on the moving body of the invention and the assembly of the motor, the reducer and the gear is arranged on the lever; the lever only has one rotational degree of freedom around the plug axes and the gear installed on the lever is pressed toward the rack by the compression spring at the other end of the lever, therefore, the distance between the gear and the rack is shortened to the minimum, thereby reaching the aim of reducing the backlash of mutually meshed gear and rack and finally playing a role in reducing the backlash.

Description

The Leverage Mechanism for Reducing the Backlash of the Rack and Pinion Transmission (1) Technical field The invention relates to a lever mechanism, in particular to a lever mechanism for reducing backlash in rack and pinion drives. (2) Background technology Due to manufacturing and installation errors, as well as to compensate for thermal deformation and provide space for storing lubricating oil, the rack and pinion meshing needs to leave a minimum backlash; the traditional method is to use double-plate gears to control the gap to reduce the rack and pinion meshing The method of empty return, this method of reducing empty return increases the processing cost and installation cost, and the double-plate gear must be adjusted regularly according to the usage; another common method is to design and process the gear shaft of the installed gear as an eccentric shaft, through The relative position of the gear and the rack is controlled to control the backlash, thereby effectivel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16H19/04

Inventor 王立权赵亚楠杜宏旺

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com