Energy-saving device and operation process for absorption-stabilization system

An absorption stabilization system and energy-saving device technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve the problems of increasing the energy consumption of the absorption stabilization system, increasing the energy consumption of the device, high absorption rate and desorption rate, etc., to achieve Significant energy-saving effect and economic benefits, increased yield, and reduced lean gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

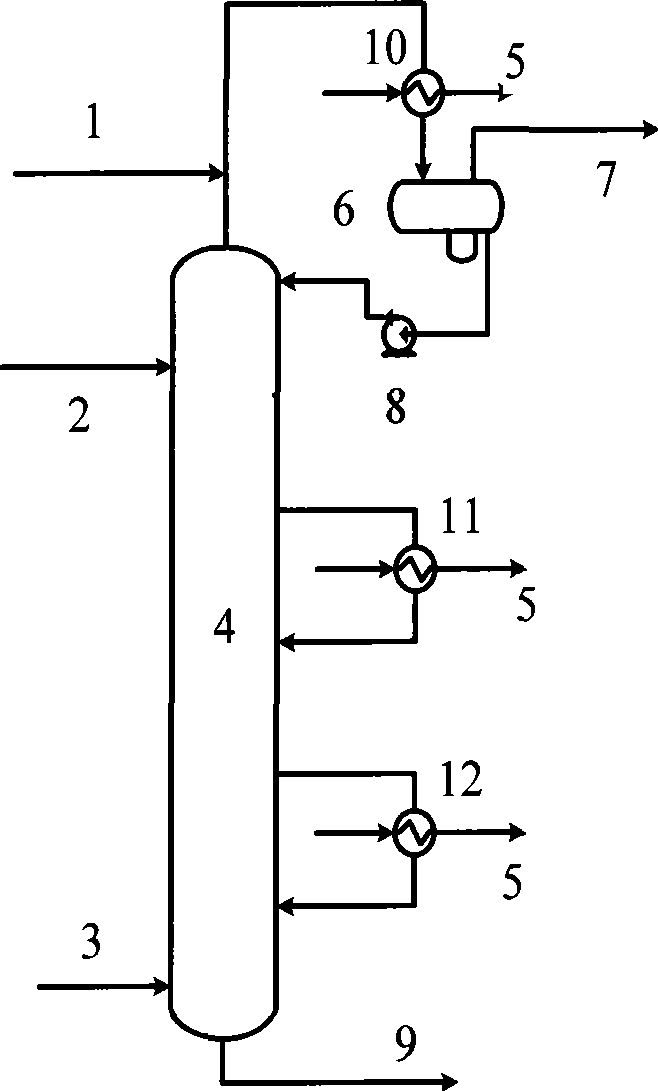

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

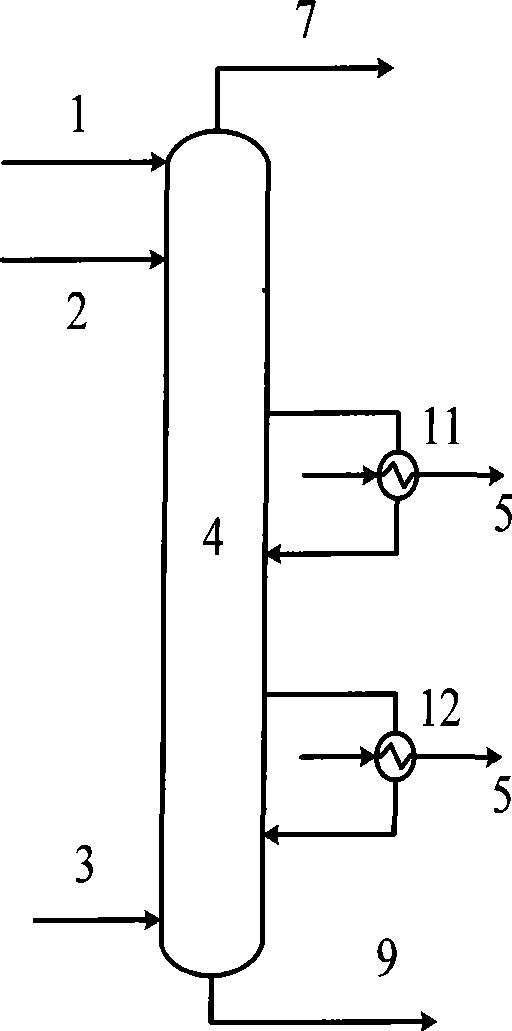

[0016] The process flow of the absorption stabilization system generally adopted in the comparison industry, such as figure 1 structure and connections shown.

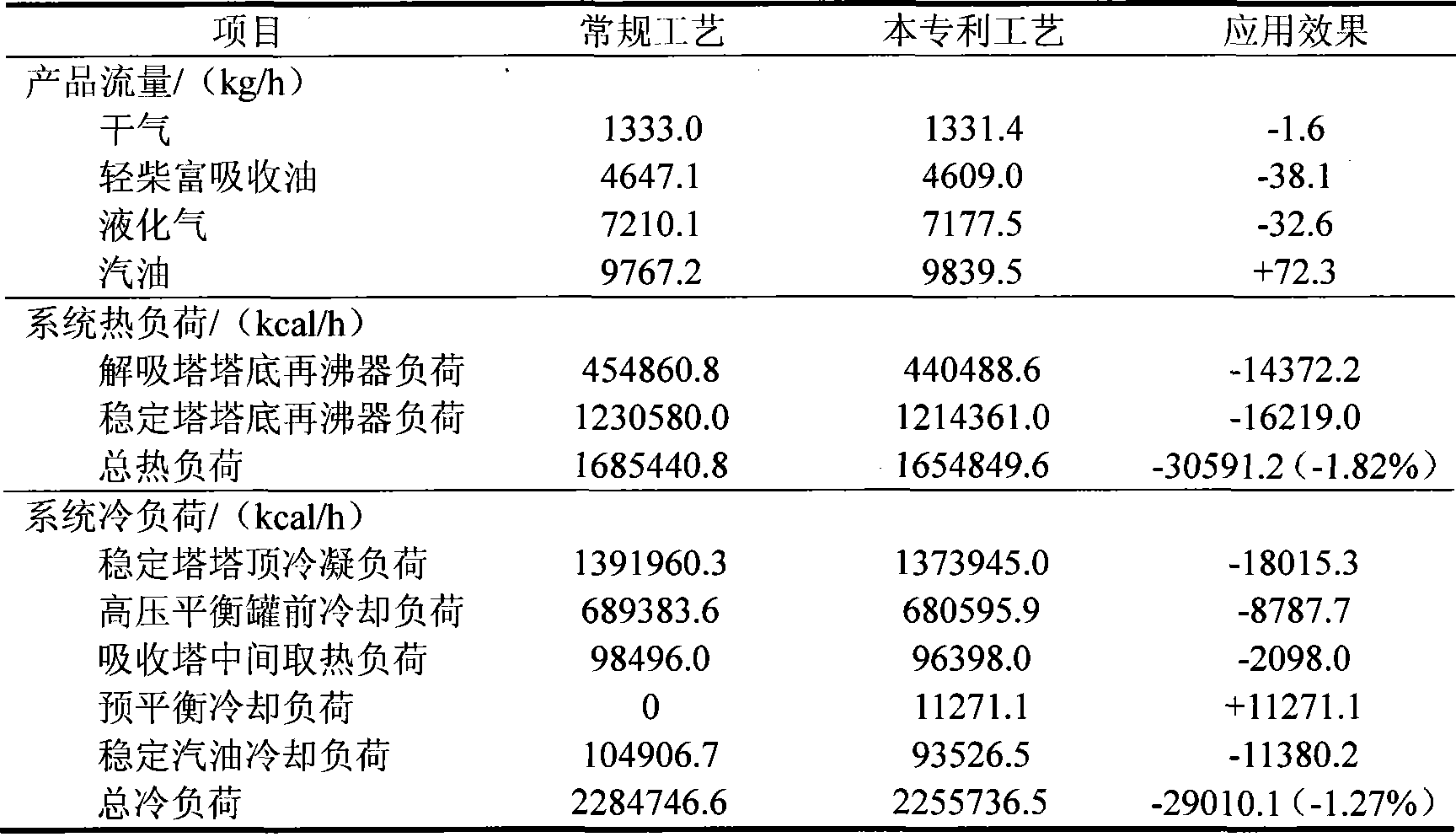

[0017] Taking a refinery with a catalytic processing capacity of 0.012Mt / a as an example to simulate, the flow rate of naphtha is 11000kg / h, the flow rate of compressed rich gas is 8000kg / h, and the flow rate of light diesel oil is 4000kg / h: naphtha absorbent (2 ) temperature is 40 DEG C, enters the absorption tower (4) top; Stabilized gasoline supplementary absorbent (1) temperature is 40 DEG C, enters the absorption tower (4) tower top; Absorption tower (4) tower top lean gas (7) enters again The absorption tower is further processed; the middle and lower part of the absorption tower (4) is provided with two middle sections for heat extraction (11, 12) to take away the heat released during the absorption pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com