Milk powder packing bag and preparing method thereof

A packaging bag and milk powder technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of harming consumers' health, poor heat resistance, and small market share, etc., achieve good aluminum layer adhesion, improve Cooling effect, effect of ensuring no odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

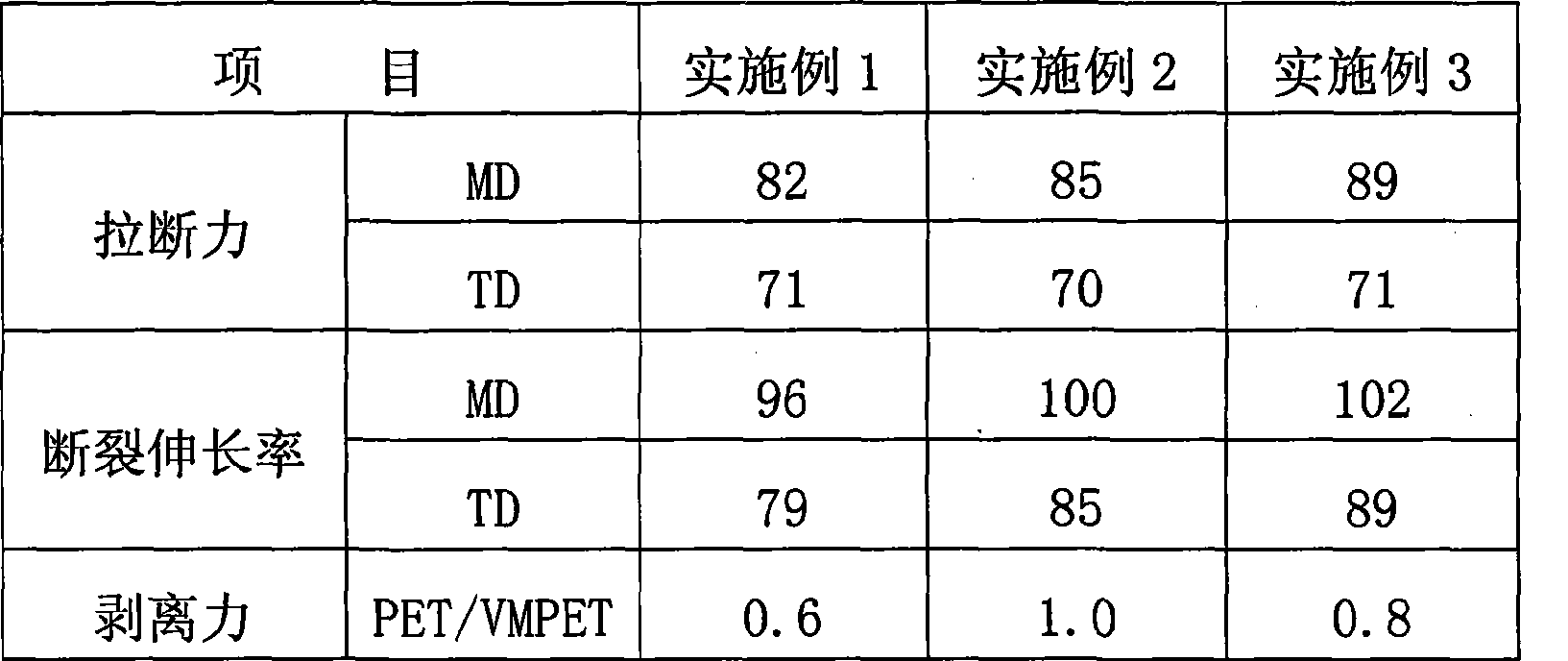

Embodiment 1

[0064] Milk powder packaging bag, from the inside to the outside, is an antibacterial inner film layer, a high-barrier vacuum aluminized film layer, and a PET polyester film layer. The preparation method:

[0065] a) In the PET film printing process: the PET polyester is polyethylene terephthalate. The ink is benzene-free ink, the ambient temperature is 20°C, the layered plate drying temperature is 55°C, the air inlet pressure and exhaust air pressure are 80mmHg, and the printing speed is 180m / min;

[0066] b) Preparation process of high-barrier vacuum aluminized film: prepared according to the method of z1200310112661.5.

[0067] c) The preparation process of antibacterial inner film, including feeding process, material plasticizing extrusion process, inflation traction process, air ring process, herringbone splint process, traction roller traction process, corona treatment process, film winding process:

[0068] In the described feeding process:

[0069] Composite layer: 5...

Embodiment 2

[0079] Milk powder packaging bag, from the inside to the outside, is an antibacterial inner film layer, a high-barrier vacuum aluminized film layer, and a PET polyester film layer. The preparation method:

[0080] a) In the PET film printing process: the PET polyester is polyethylene terephthalate. The ink is benzene-free ink, the ambient temperature is 25°C, the drying temperature for large area full plate is 75°C, the air inlet pressure and exhaust air pressure are 85mmHg, and the printing speed is 190m / min;

[0081] b) Preparation process of high-barrier vacuum aluminized film: prepared according to the method of z1200310112661.5.

[0082] c) The preparation process of antibacterial inner film, including feeding process, material plasticizing extrusion process, inflation traction process, air ring process, herringbone splint process, traction roller traction process, corona treatment process, film winding process:

[0083] In the described feeding process:

[0084] Compos...

Embodiment 3

[0093] Milk powder packaging bag, from the inside to the outside, is an antibacterial inner film layer, a high-barrier vacuum aluminized film layer, and a PET polyester film layer. The preparation method:

[0094] a) In the PET film printing process: the PET polyester is polyethylene terephthalate. The ink is benzene-free ink, the ambient temperature is 25°C, the layered plate drying temperature is 60°C, the air inlet pressure and exhaust air pressure are 90mmHg, and the printing speed is 200m / min;

[0095] b) Preparation process of high-barrier vacuum aluminized film: prepared according to the method of z1200310112661.5.

[0096] c) The preparation process of antibacterial inner film, including feeding process, material plasticizing extrusion process, inflation traction process, air ring process, herringbone splint process, traction roller traction process, corona treatment process, film winding process:

[0097] In the described feeding process:

[0098] Composite layer: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com