Soil pollution thermal desorption restoration processing system

A soil pollution and treatment system technology, applied in the field of repair treatment system, can solve the problems of small treatment capacity, unable to meet the large-scale engineering application needs of polluted sites, and no thermal desorption treatment system has been found, so as to achieve good applicability and eliminate The effect of the secondary pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated below through specific examples of implementation.

[0027] A chemical pollution site in Suzhou, the main pollutants are benzene series, such as benzene, toluene, xylene, etc.

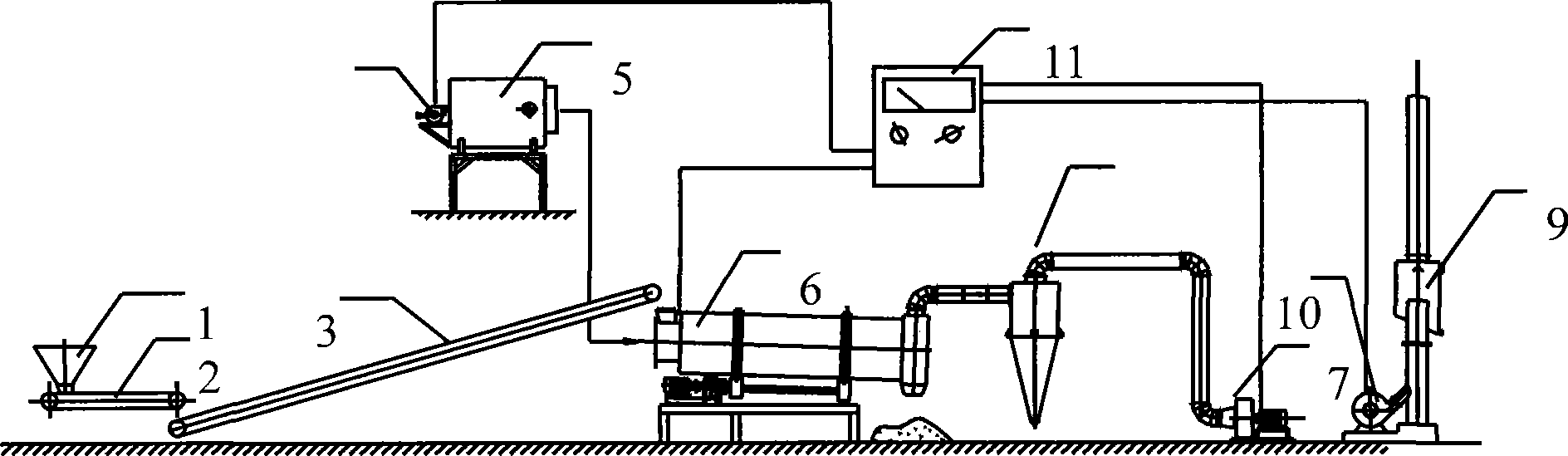

[0028] The invention consists of a heat source system, a feed system, a thermal desorption system, a control system and a tail gas treatment device.

[0029] The feeding system consists of a hopper 1, a weighing belt scale 2, and a feeding belt conveyor 3. After the polluted soil is pretreated by the mesh screen, the particle size is less than 1cm, and then enters the weighing belt scale 2 through the hopper 1, and the feeding belt conveyor 3, and then enters the thermal desorption system. The measurement belt scale 2 is 0.5m wide and 2.0m long, placed in parallel, and the feeding belt conveyor 3 is 0.4m wide and 6.0m long, placed at 30° to 45°. Both are controlled by motors to control the transmission speed, and the motors are connected to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com