Attic type gravity dust collector

A gravity dust collector and attic technology, applied in chemical instruments and methods, waste heat treatment, dispersed particle filtration, etc., can solve the problems of low dust removal efficiency, inability to deal with leaked smoke, and dust accumulation that can only be cleaned manually

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

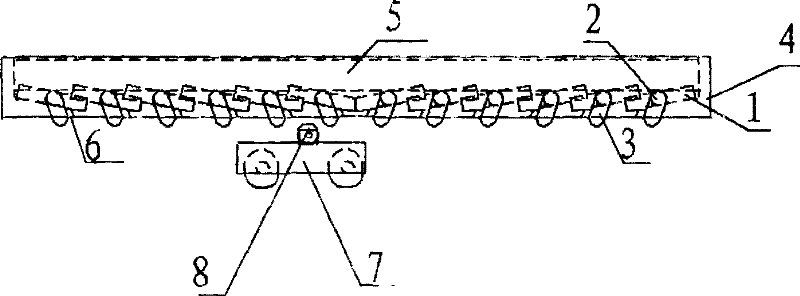

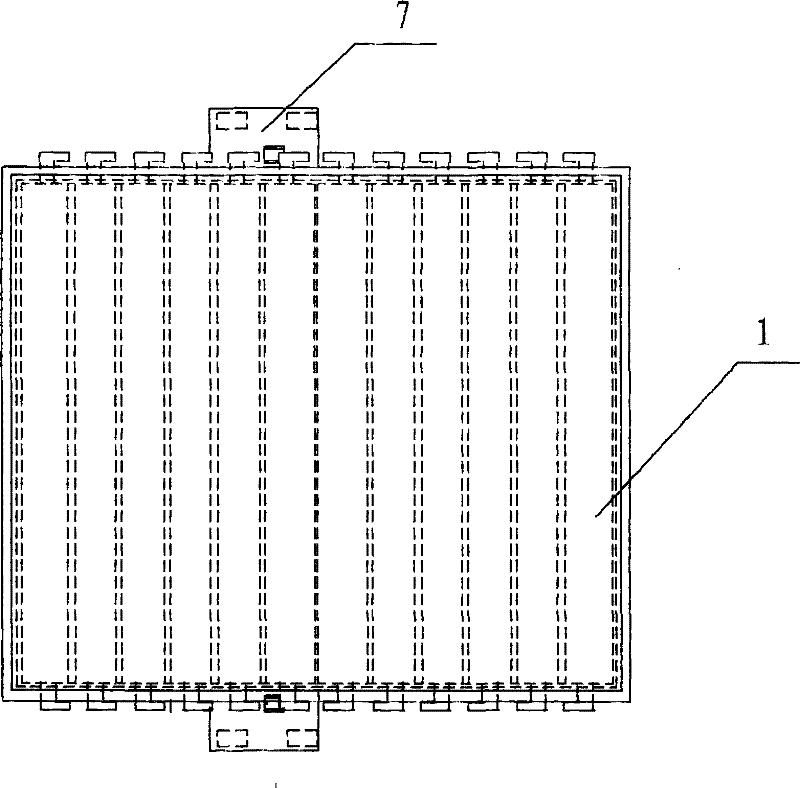

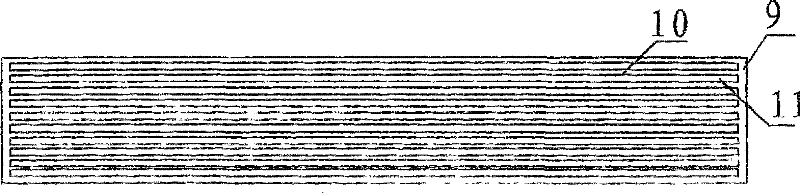

[0013] As shown in the figure: a special attic gravity dust collector for electric arc steelmaking furnace, which is composed of a metal structure gravity settling chamber (5) installed on the top of the workshop above the electric arc steelmaking furnace and a cleaning chamber installed on the crane rail in the workshop Gray car (7) is made up of two major parts. It is characterized in that the bottom of the metal structure gravity settling chamber (5) fixed on the beam of the factory building is composed of a group of tiltable clapboard type filters (1). The clapboard filter (1) is connected with the upper cover (4) of the gravity settling chamber through the rotary shaft (2) of the clapboard filter. The rotating shaft (2) of the clapboard filter is connected with the rotating block (3) of the clapboard filter on the outside of the gravity settling chamber loam cake (4). The filter element dividing plate (10) is fixed on the filter element frame (9), and a three millimeter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com