Determining surface and thickness

A high-strength technology, used in textiles and papermaking, using re-radiation, sensors, etc., can solve the problems of reducing measurement accuracy and reliability, inaccurate measurement, etc., and achieve the effect of reducing diffuse reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Although measurements have been made on non-diffuse materials, the present scheme can also be applied in particular to measuring diffuse materials. The diffusing material includes paper, fabric, metal coated with diffusing material, skin, various powders whose surface (or thickness) needs to be determined.

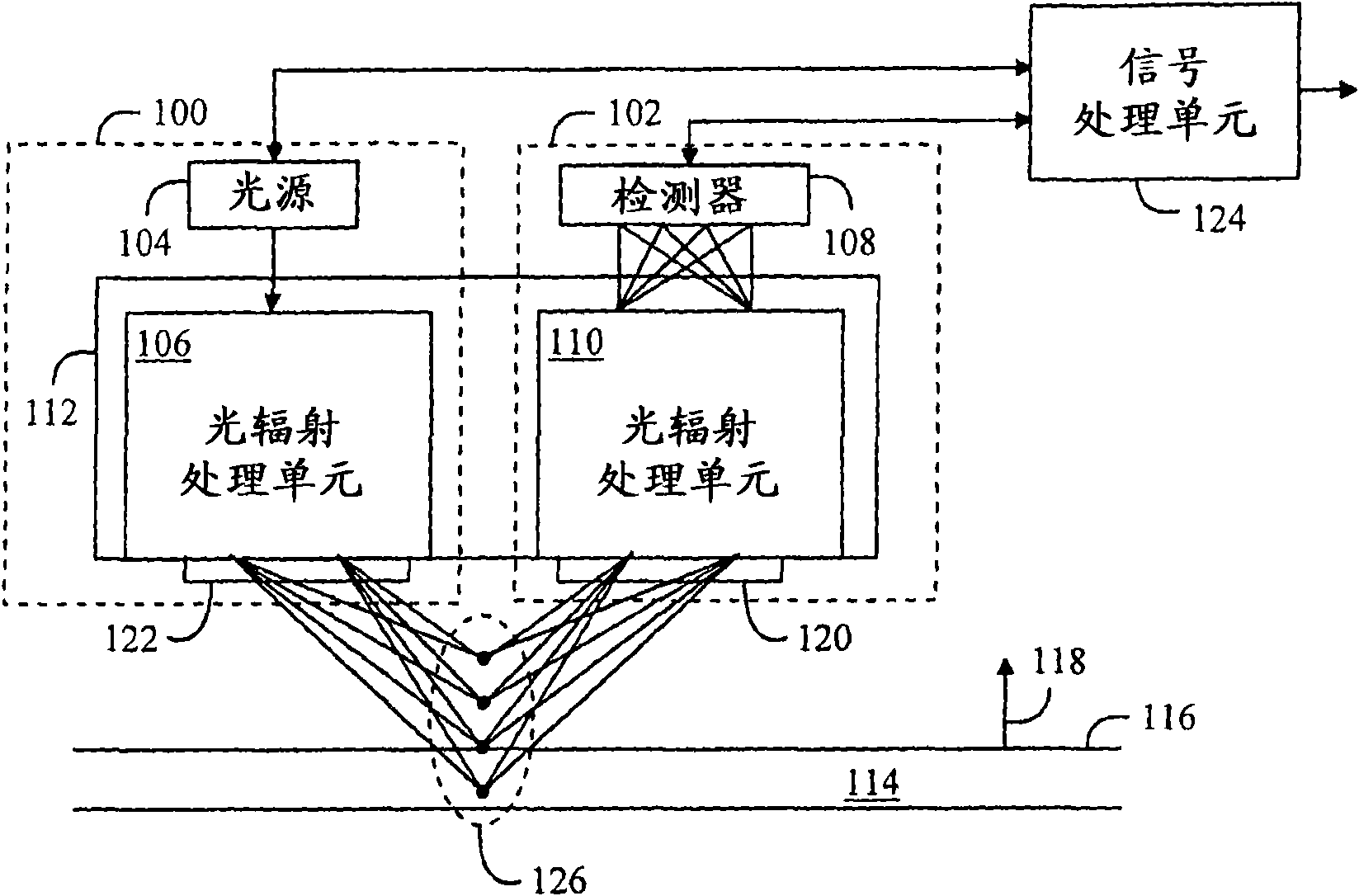

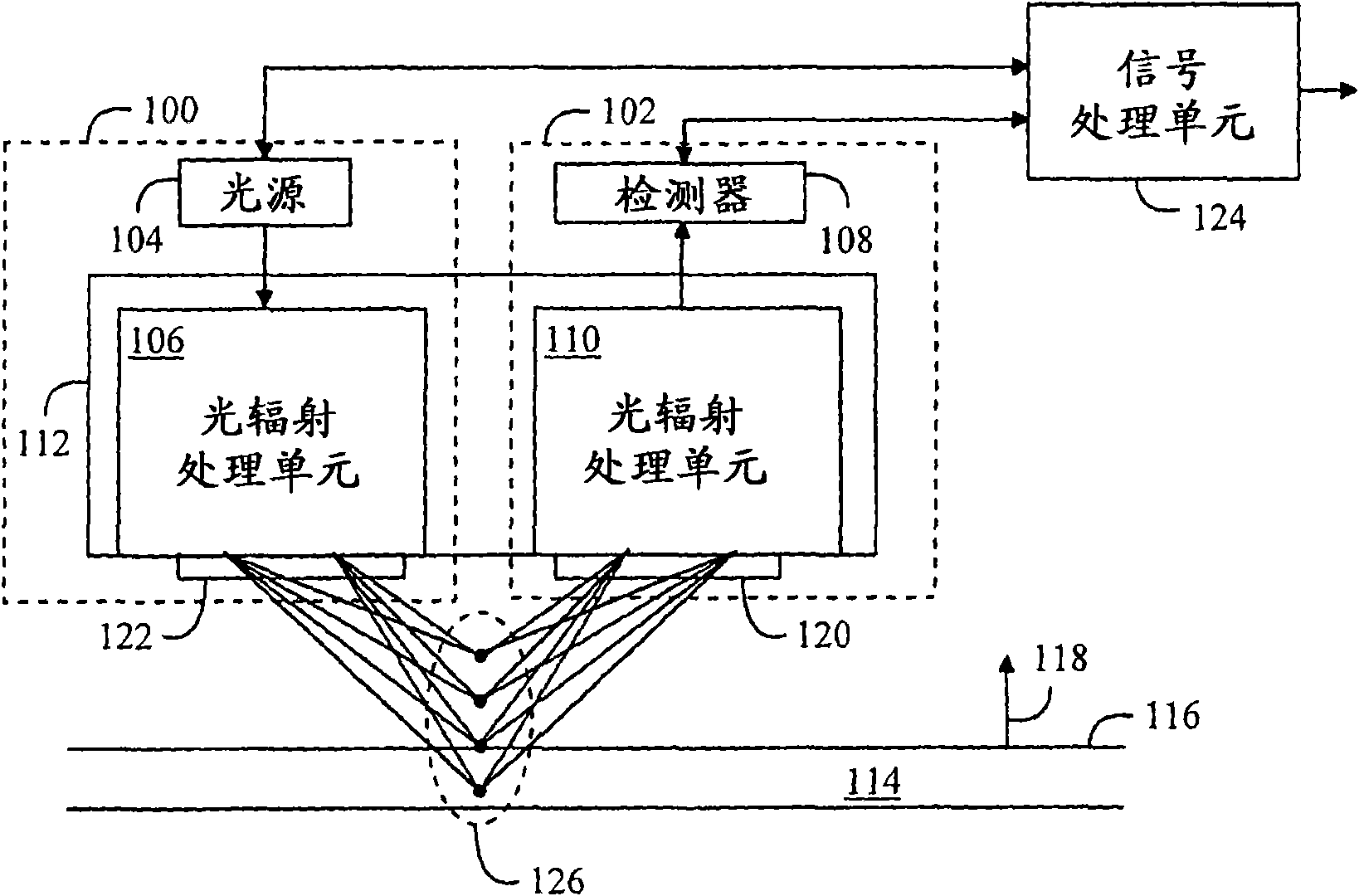

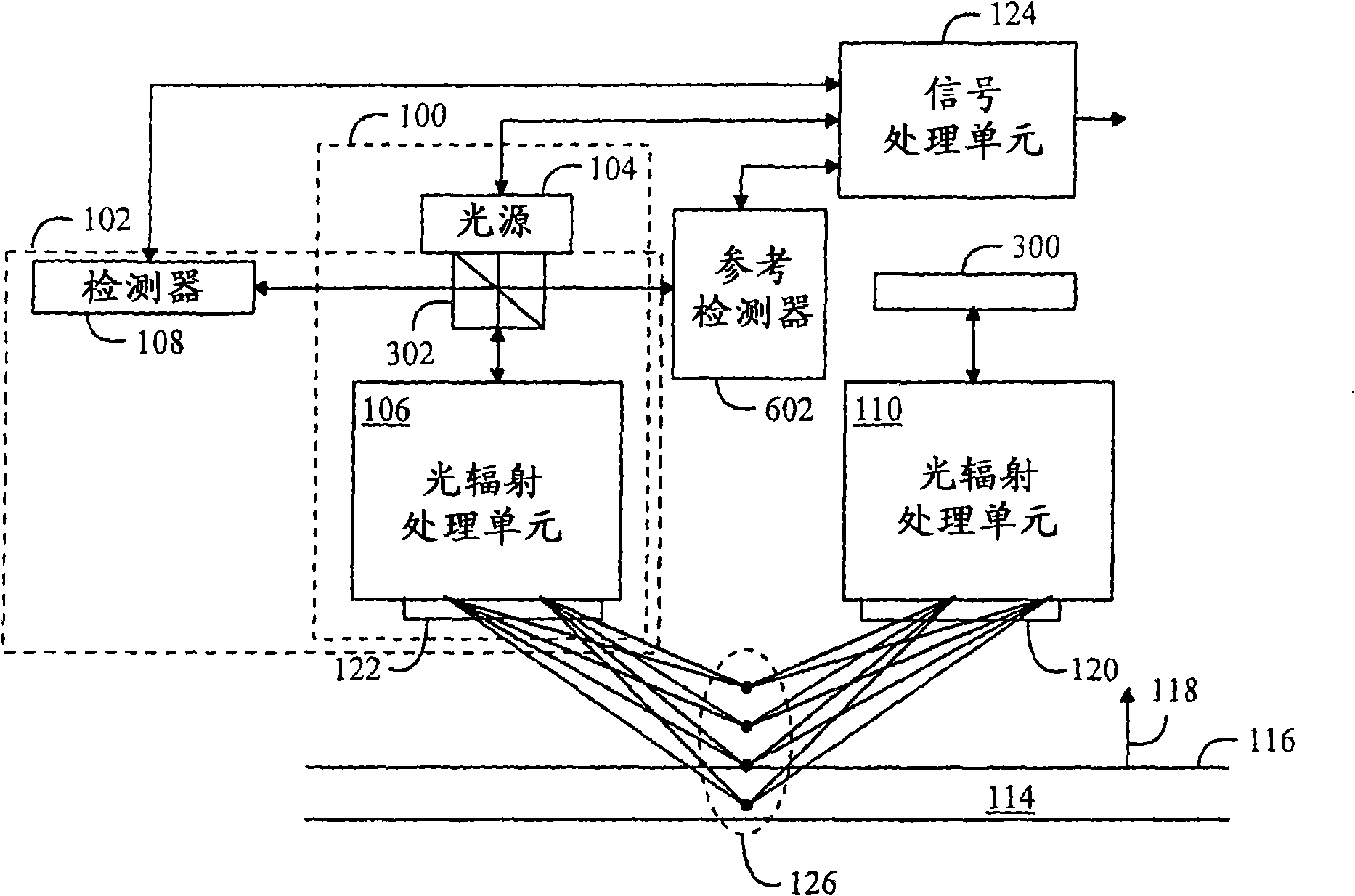

[0028] let's pass now figure 1 Examining the present scheme, in the figure the measuring device comprises a transmitter part 100 and a receiver part 102 separated from each other. The transmitter section 100 includes a light source 104 and a first optical radiation processing section 106 . In this application, optical radiation refers to electromagnetic radiation having a wavelength band between ultraviolet radiation (wavelength approximately 50 nm) and infrared radiation (wavelength approximately 1 mm). The receiver section 102 includes a detector 108 and a second optical radiation processing section 110 . The optical radiation processing sections 106 and 110 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com