Optical film material of lateral light type backlight module

An optical film, backlight module technology, applied in optics, nonlinear optics, components of lighting devices, etc., can solve problems such as cost and manufacturing threshold reduction, cost reduction, etc., to achieve the effect of saving number without affecting brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

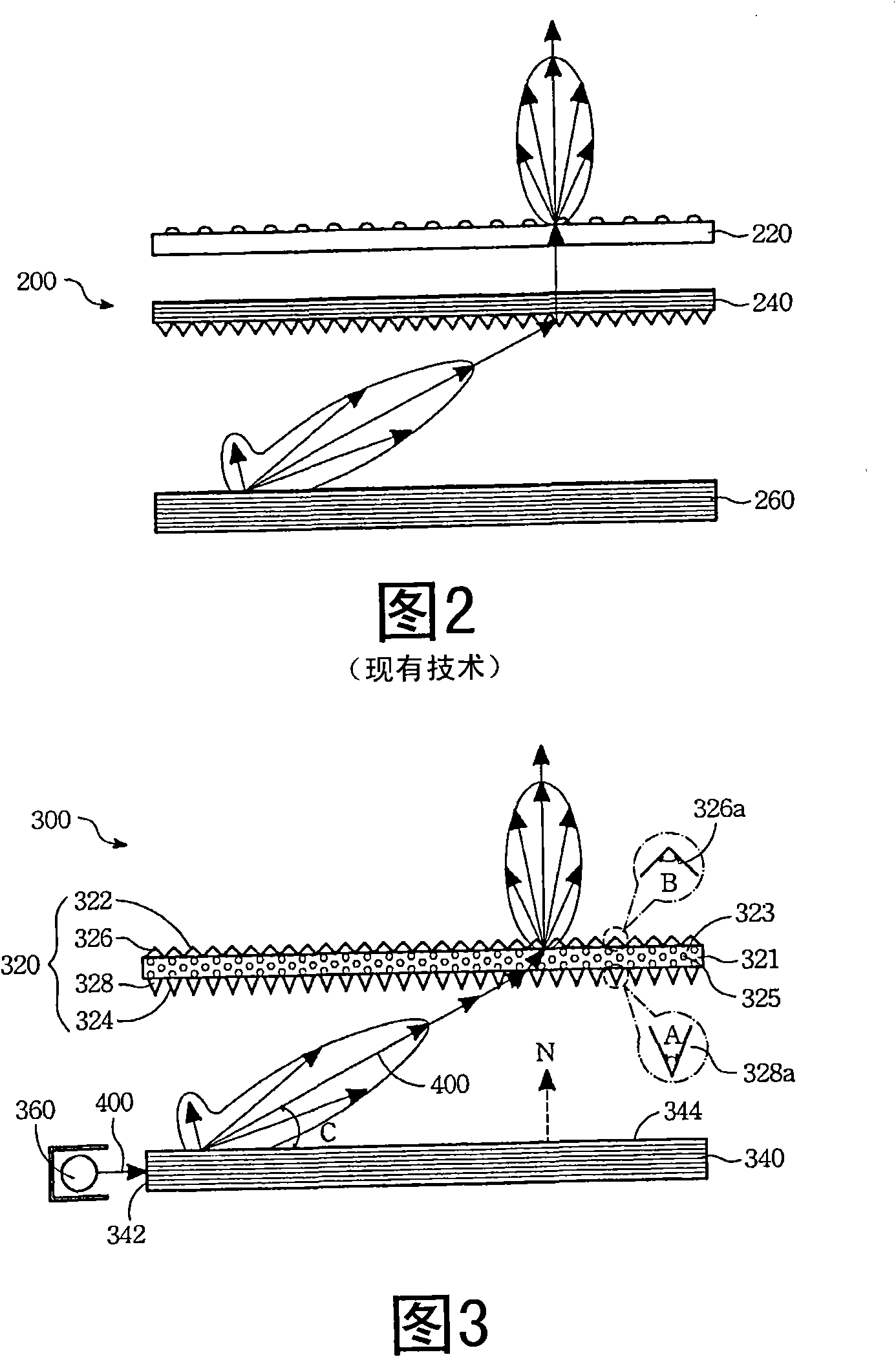

[0022] The aforementioned and other technical content, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments in conjunction with the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

[0023] Referring to FIG. 3 , the edge-lit backlight module 300 includes an optical film 320 , a light guide plate 340 and a light source 360 . The optical film material 320 has an upper surface 322 and a lower surface 324 . The lower surface 324 is opposite to the upper surface 322 . The upper surface 322 is the surface of the upper prism structure 326 . The lower surface 324 is the surface of the lower prism structure 328 . Between the upper prism structure 326 and the lower prism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com