Safe pressure relief device suitable for online checkout

A pressure relief device and safety technology, applied in the direction of safety valves, valve devices, measuring devices, etc., can solve the problem of opening of safety valves, difficulty in online repair, replacement and calibration of pressure vessel safety pressure relief devices, difficulty in pressure vessel safety release Problems such as repair, replacement and calibration of pressure devices, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

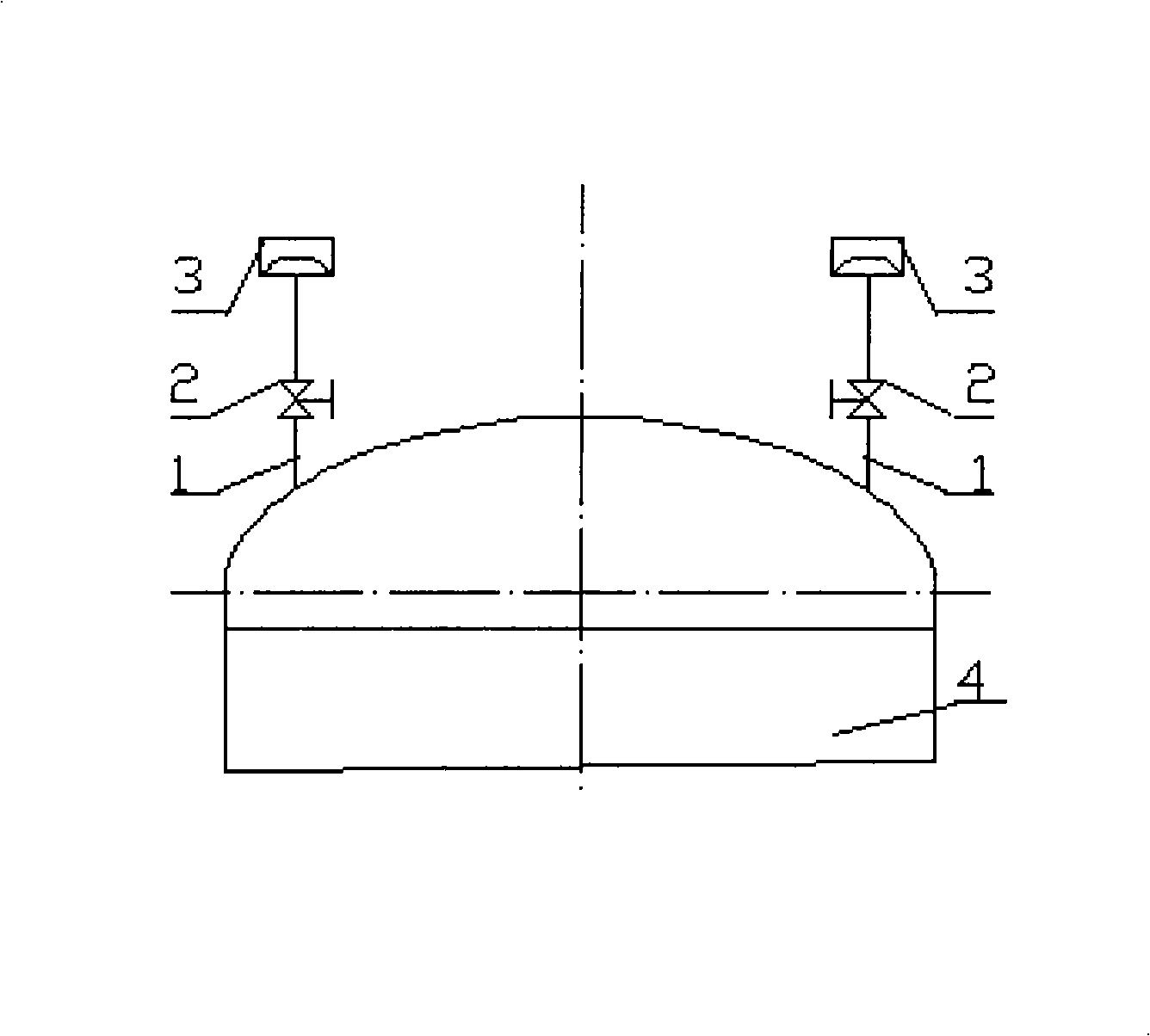

[0015] Embodiment: Referring to Fig. 2, the present invention includes two sets of inlet pipeline 1, inlet shut-off valve 2, common safety pressure relief element 3 (such as: safety valve, explosion-proof disk, etc.) and pressure vessel body 4, which are respectively arranged on on the head of the pressure vessel. During the normal production process, the two inlet stop valves 2 are both open. When the pressure in the pressure vessel exceeds the operating pressure specified by the ordinary safety pressure relief element 3 due to some abnormal reason, the one with the lower operating pressure will A set of safety pressure relief device will start to act, and the pressure in the pressure vessel will drop. When the pressure drops to the normal range, the safety pressure relief element 3 will be automatically closed (such as: the disc of the safety valve is back seated), Or by artificially closing the inlet shut-off valve 2, the purpose of restoring normal production can be achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com