Thin-tube-plate segment anodic protection stainless steel shell-and-tube concentrated sulfuric acid cooling tower

A technology of anodic protection and stainless steel tubes, which is applied to fixed tubular conduit components, sulfur compounds, heat exchanger shells, etc., can solve the problems of high investment cost and large scrap loss of concentrated sulfuric acid coolers, and achieve reduction of scrap costs and savings Stainless steel material, the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

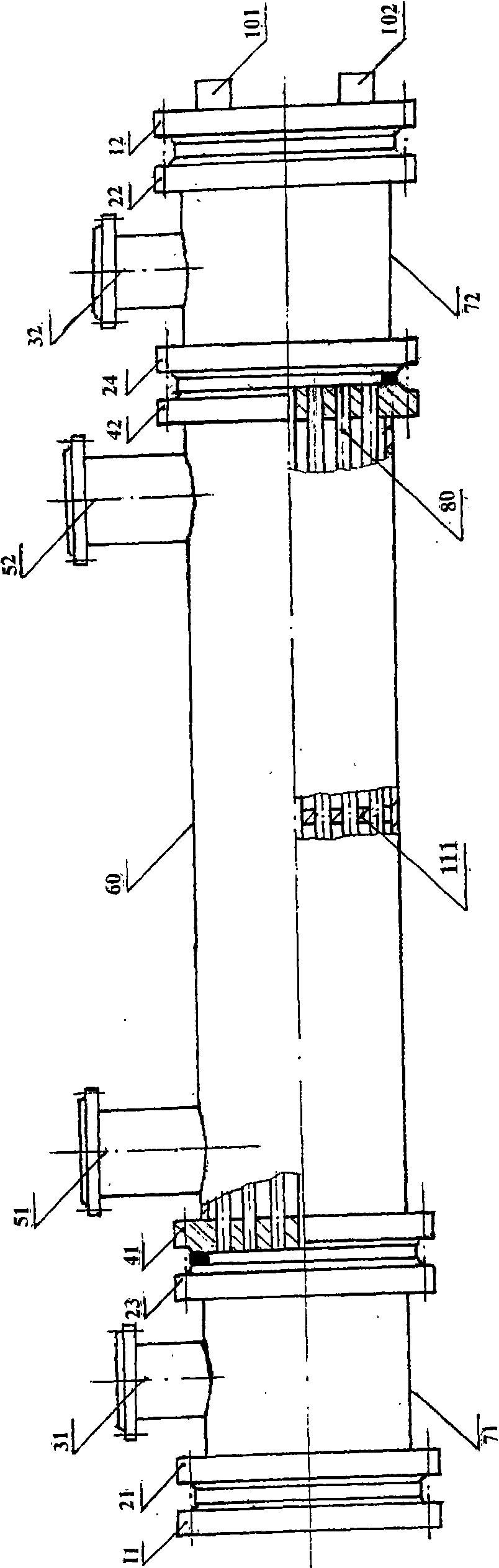

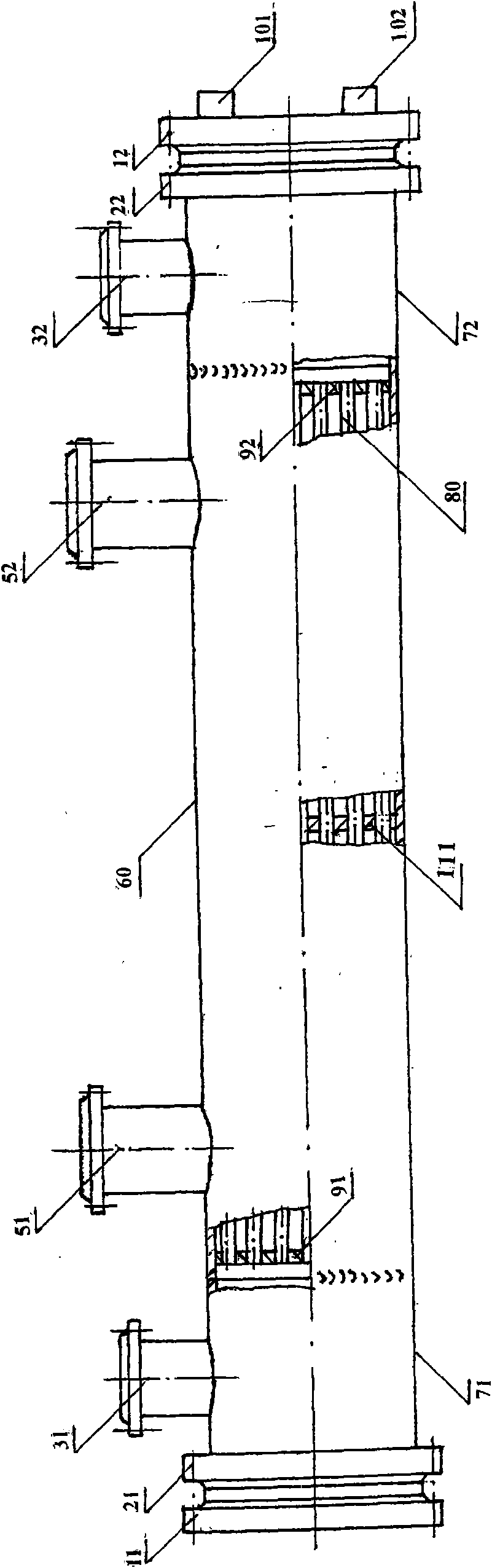

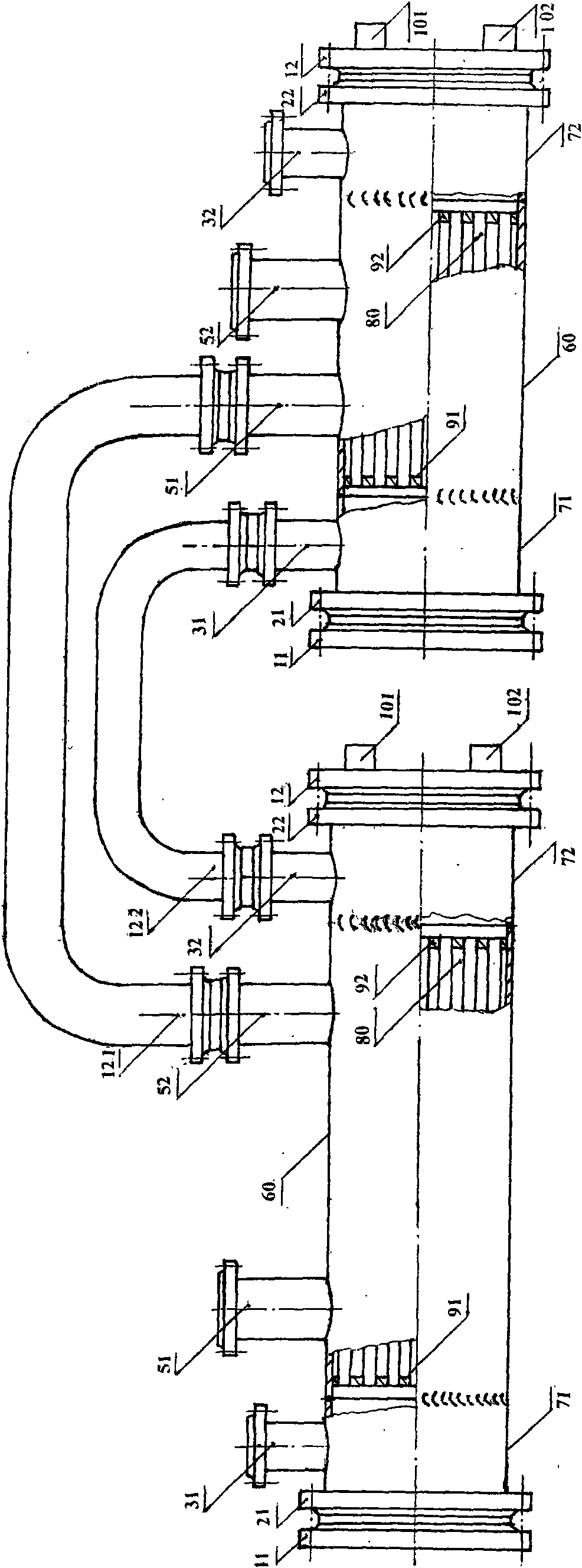

[0012] The specific embodiment of the present invention refers to accompanying drawing.

[0013] The present invention is composed of shell side, tube side and anode protection parts. The shell side runs concentrated sulfuric acid, flows through the inlet acid pipe, the outlet acid pipe, the acid side of the left thin tube plate, the acid side of the right thin tube plate, and the shell side tube. On the inner side of the body, the acid flow channel formed by the heat exchange tube bundle and the baffle is made of stainless steel. The water side of the cover, the inside of the left water tank cylinder, the inside of the right water tank cylinder, the water measurement of the left thin tube plate, the water flow channel formed by the water side of the right thin tube plate and the inside of the heat exchange tube bundle, and the anode protection components arranged on the shell side , Their materials are all carbon steel except the last four are stainless steel.

[0014] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com