Explosion cladding rolled double-sided stainless steel composite thin strip

A compound rolling and stainless steel technology, applied in the direction of manufacturing tools, non-electric welding equipment, layered products, etc., can solve the problems of not forming a scale and not being able to replace stainless steel, etc., and achieve the effect of lowering prices, saving stainless steel materials, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

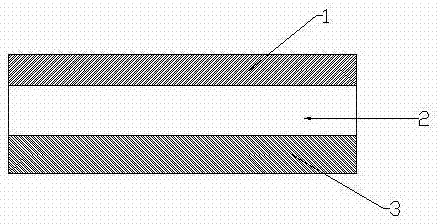

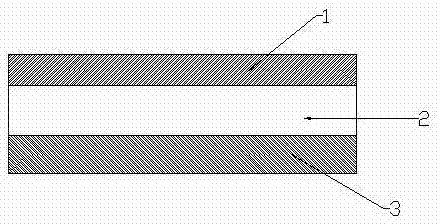

[0017] Explosive compound rolling double-sided stainless steel composite thin strip, which consists of a first stainless steel plate 1, a second stainless steel plate 3 and a carbon steel plate 2, one side of the carbon steel plate 2 is provided with the first stainless steel plate 1, and the other side is provided with the second stainless steel plate Plate 3 is a double-metal clad strip formed by explosive cladding, hot rolling, and cold rolling.

[0018] The production process of the explosive composite rolling double-sided stainless steel composite thin strip is as follows: using the method of explosive welding to make a composite billet, which is hot-rolled into a medium plate or a hot-rolled coil, and then cold-rolled into a cold-rolled coil. Strip material; the thickness of the thin strip after cold rolling is 0.5mm; the connection interface between the stainless steel plate and the carbon steel plate is combined by interatomic bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com