Zone melting purification device and method of purifying phenylformic acid by adopting same

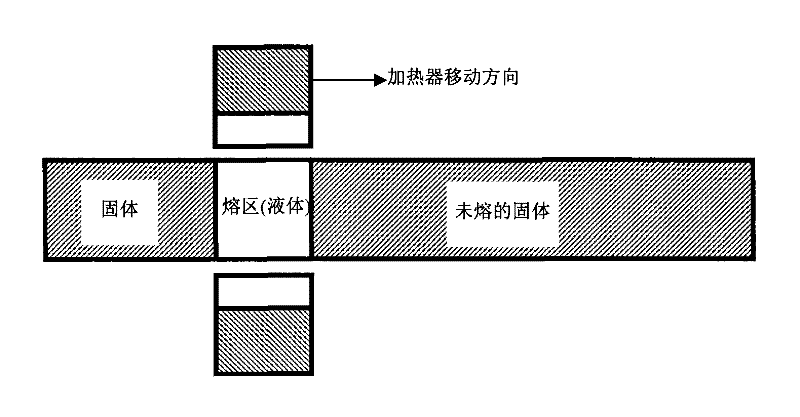

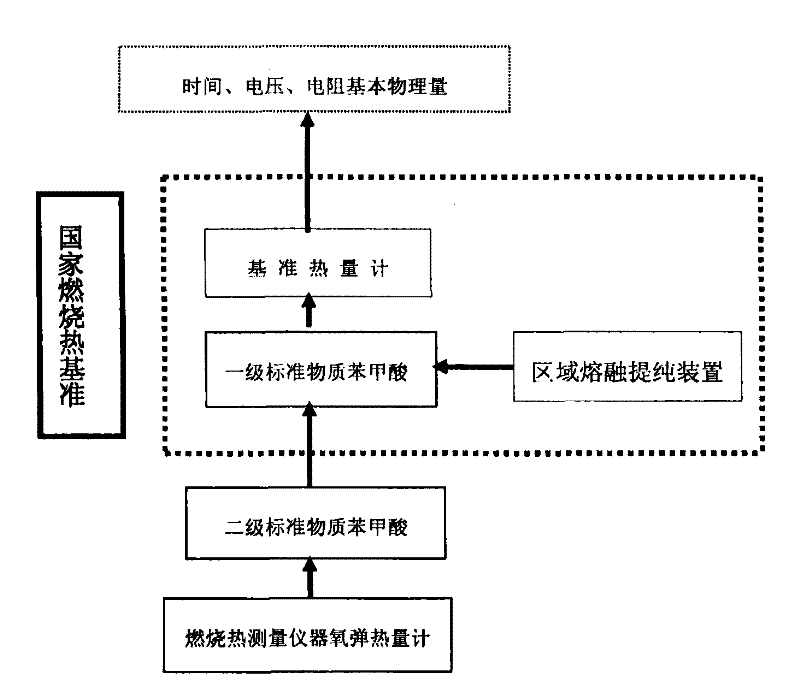

A zone melting, benzoic acid technology, applied in chemical instruments and methods, separation methods, separation/purification of carboxylic acid compounds, etc., can solve the problem that the up and down movement of the heating furnace and the temperature control cannot be accurately and automatically controlled, and the benzoic acid can no longer be increased. Purity, low degree of automation, etc., to achieve the effect of facilitating the generation of the molten zone, easy to observe the status of the molten zone, fast heat transfer and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

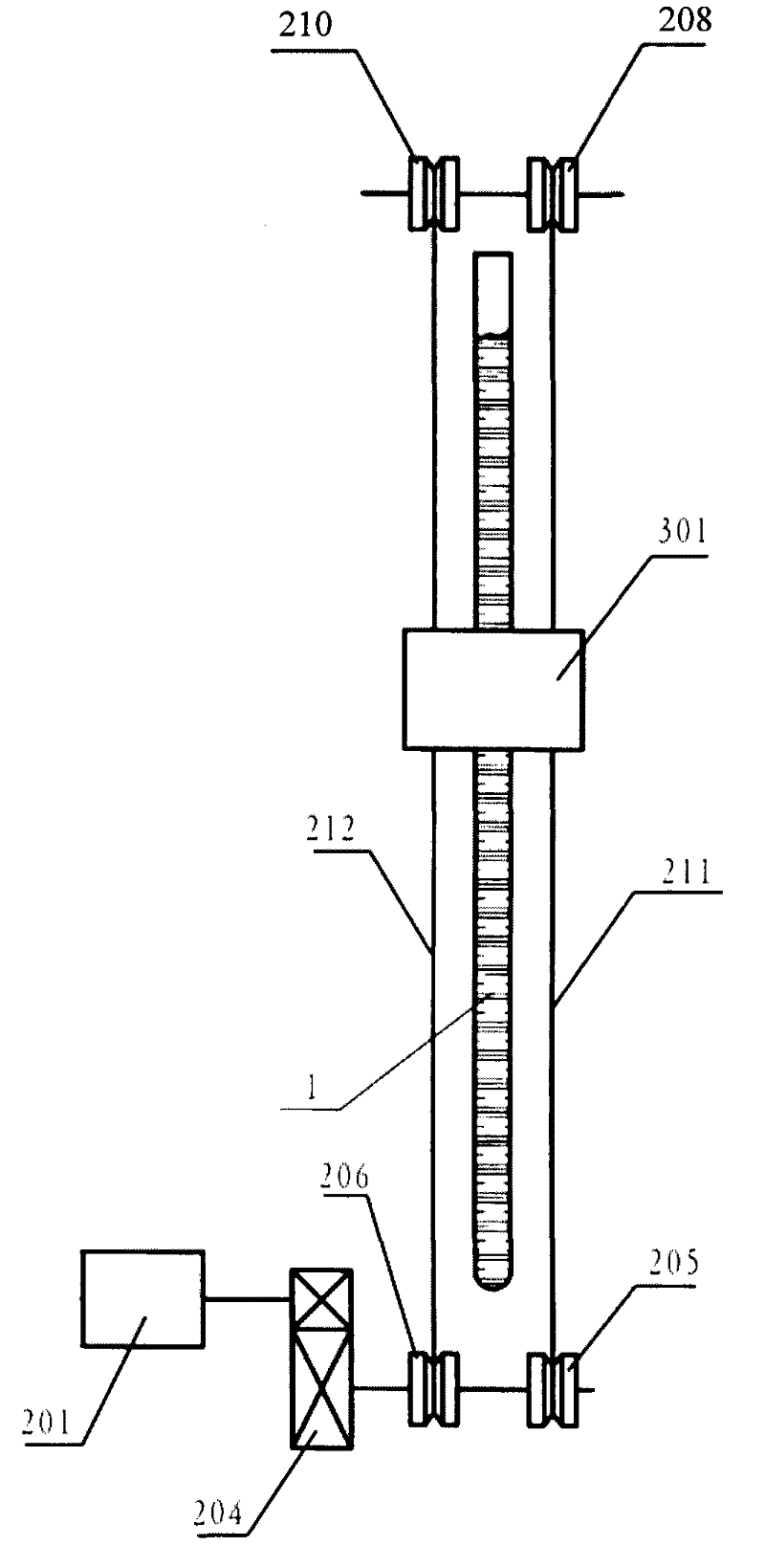

[0074] Such as image 3 The schematic structural diagram of the regional melting purification device shown includes a sample tube 1, a supporting part (not shown in the figure), a heating furnace and a transmission part. The sample tube 1 is long cylindrical and is used to hold the purified sample. The transmission components include a synchronous motor 201, a reduction box 204, a first transmission chain 211 and a second transmission chain 212, and the synchronous motor 201 drives the first transmission gear 205 and the second transmission gear 205 on the same axis as the reduction box 204 after being decelerated by the reduction box 204. The transmission gear 206 rotates, thereby driving two transmission chains 211 and 212 for transmission.

[0075] The heating furnace is to provide a heat source for the sample in the sample tube to generate a melting zone, so the heating furnace can also be replaced by other forms of products that can provide a heat source. The heating fur...

Embodiment 2

[0078] Such as Figure 4 , Figure 5 As shown, the regional melting purification device of the present invention includes: a sample tube 1 for containing the purified sample; a support member for supporting and fixing the sample tube 1; Heating furnace; a transmission part that is connected with the heating furnace and drives the heating furnace to move.

[0079] The material of the sample tube 1 is acid-resistant hard glass. The glass has stable chemical properties and will not pollute the sample. It is easy to observe the state of the melting zone. The thermal conductivity is small, the heat transfer is fast, and the heat loss is small, which is conducive to the formation of the melting zone.

[0080] The supporting part includes a base 101 and a bracket 102 fixed on the base. A beam 103 is arranged at the upper end of the bracket 102. A positioning hole is opened in the middle of the beam 103. The sample tube 1 is passed through the positioning hole, so the sample tube 1 ...

Embodiment 3 4

[0086] In order to enable the sample tube 1 to be at different inclination angles to increase the cross-sectional area of the sample, reduce the internal tension of the sample tube and prevent the sample tube from bursting, the difference between the third and fourth embodiments and the first and second embodiments is that an additional Figure 6 The angle adjuster shown in includes a first positioning plate 402, a second positioning plate 403 and a positioning shaft 401 which are respectively arranged opposite to the two sides of the base. The base 101 is fixed on the positioning shaft 401, and the two ends of the positioning shaft 401 are respectively connected to The bearings of the two positioning plates are connected so that the base 101 can rotate with the positioning shaft 401, and the fan-shaped plate 404 is set on the side of the base 101 corresponding to the first positioning plate 402, such as Figure 7 As shown, seven positioning holes 405 are set on the fan-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com