Oil fume separation and purification apparauts

A kind of oil fume separation and purification device technology, which is applied in the direction of combination device, separation method, dispersed particle separation, etc., can solve the problems of increasing air pollution, the diffusion of oil fume odor, kitchen air pollution, etc., to achieve efficient removal of oil fume, improve the degree of purification, smoke clean air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

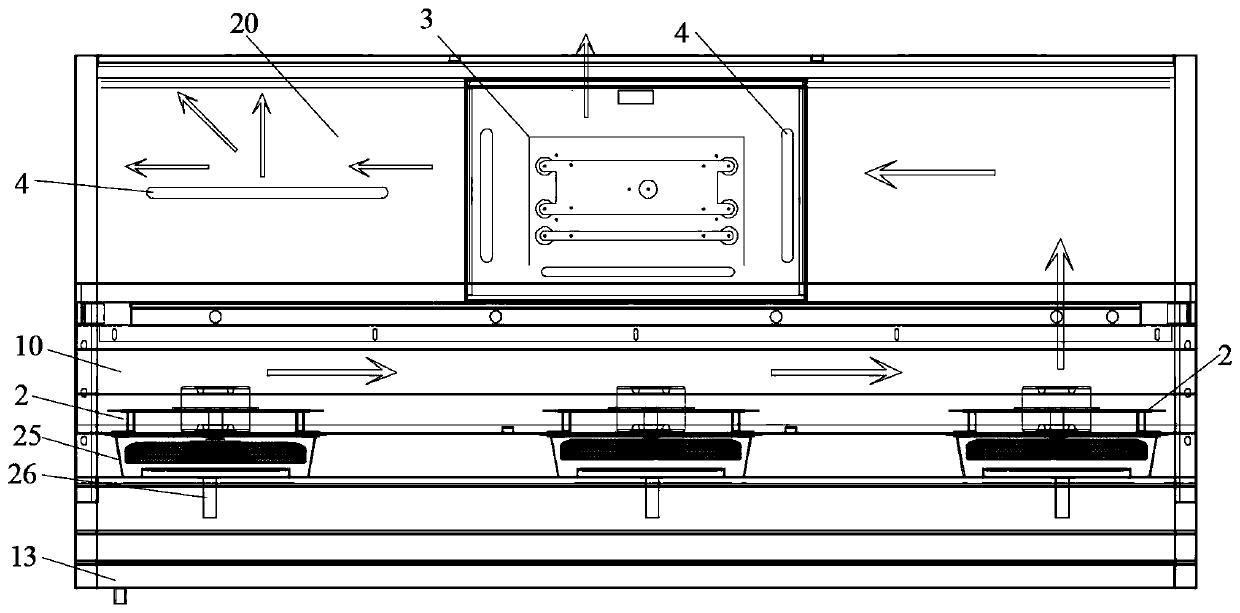

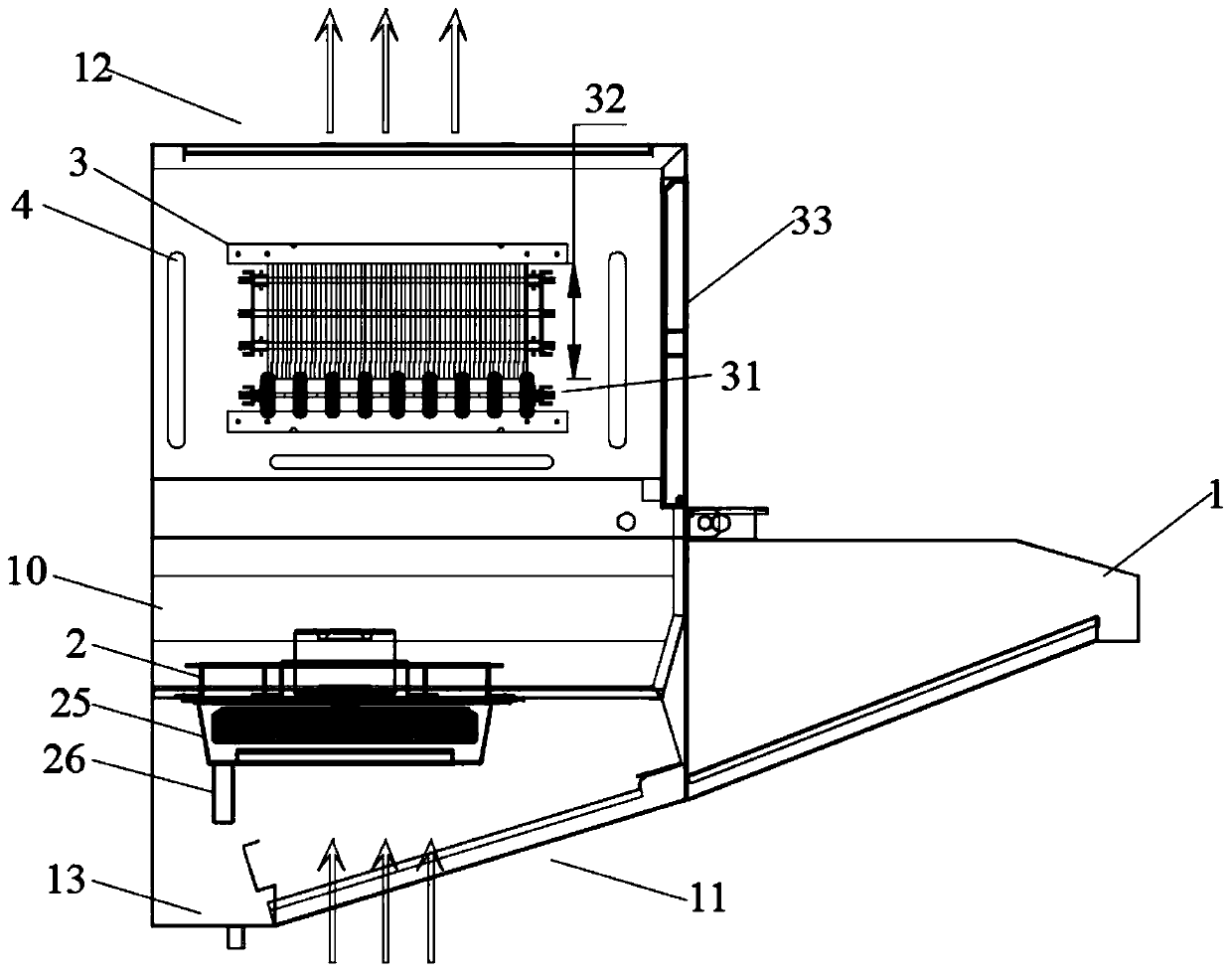

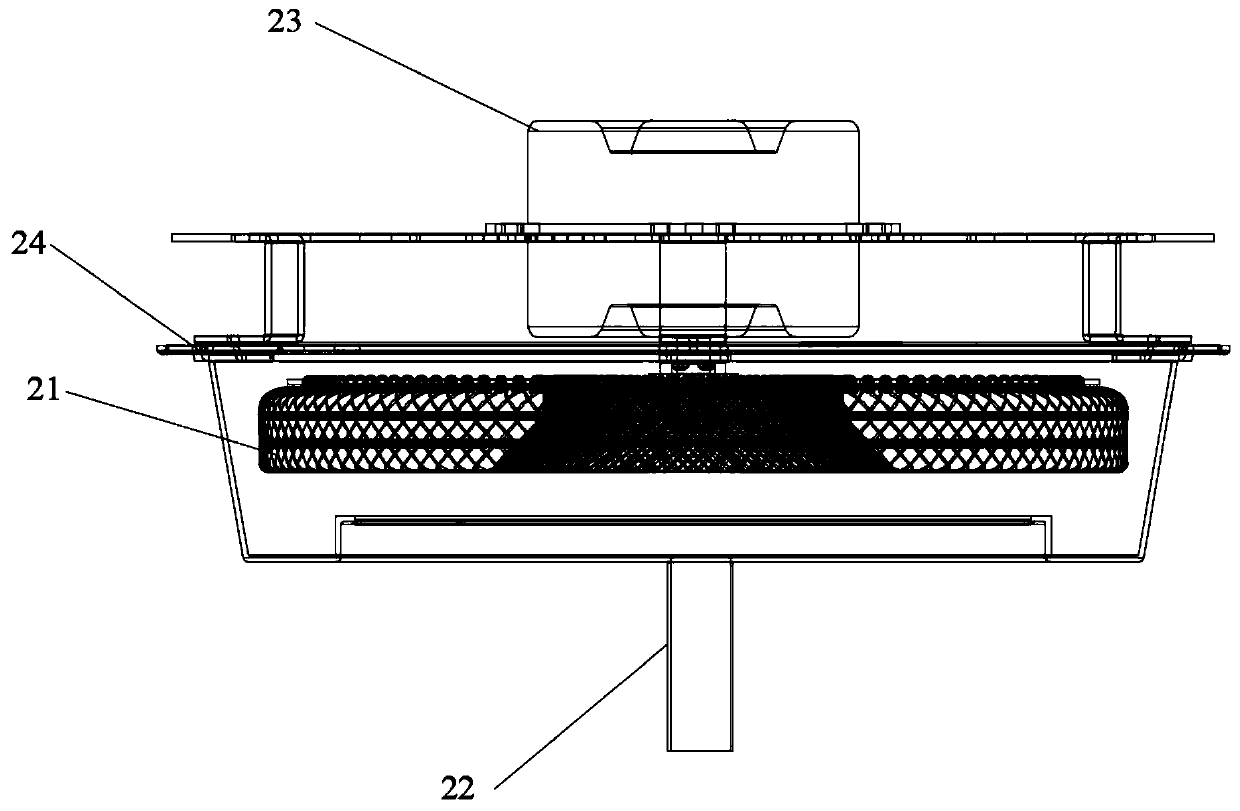

[0037] Such as figure 1 and figure 2 As shown, an oil fume separation and purification device includes an oil fume hood 1, an oil fume separation device 2 and an electrostatic field device 3 disposed therein. The bottom of the oil fume hood 1 is provided with an oil fume inlet 11, and the top is provided with an oil fume outlet. 12. The oily fume enters from the oily fume inlet 11, passes through the oily fume separating device 2 and the electrostatic field device 3 in sequence, and then is discharged from the oily fume outlet 12; a first air outlet channel 10 is provided between the oily fume separating device 2 and the electrostatic field device 3 After being separated by the oil fume separation device 2, the oily fume is gathered in the first air outlet channel 10, and then leads to the electrostatic field device 3; the interior of the electrostatic field device 3 is provided with a UV lamp 4.

[0038]In this embodiment, the oil fume separation device 2 is used to separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com