Soil phosphorus activator and manufacturing method thereof

A technology of soil phosphorus and production methods, applied in chemical instruments and methods, soil conditioning materials, climate change adaptation, etc., can solve the problems of fixation and low phosphorus availability, achieve simple process, increase soil available phosphorus content, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition of the soil phosphorus activator is based on the dry weight ratio: 40 parts of Vc fermentation waste residue, 40 parts of lignite, 4 parts of sawdust, 4 parts of natural zeolite powder, and 12 parts of coal ash. Mix Vc fermentation waste residue with lignite and sawdust, retting for 4 days under the conditions of moisture 50% and temperature 25°C, add coal ash, compost for 5 days under the condition of moisture 50% and temperature 40°C, air-dry to moisture 15%, mechanically Pulverize, pass through a 15-mesh sieve, add natural zeolite powder and mix evenly, pack separately to obtain the finished product.

Embodiment 2~9

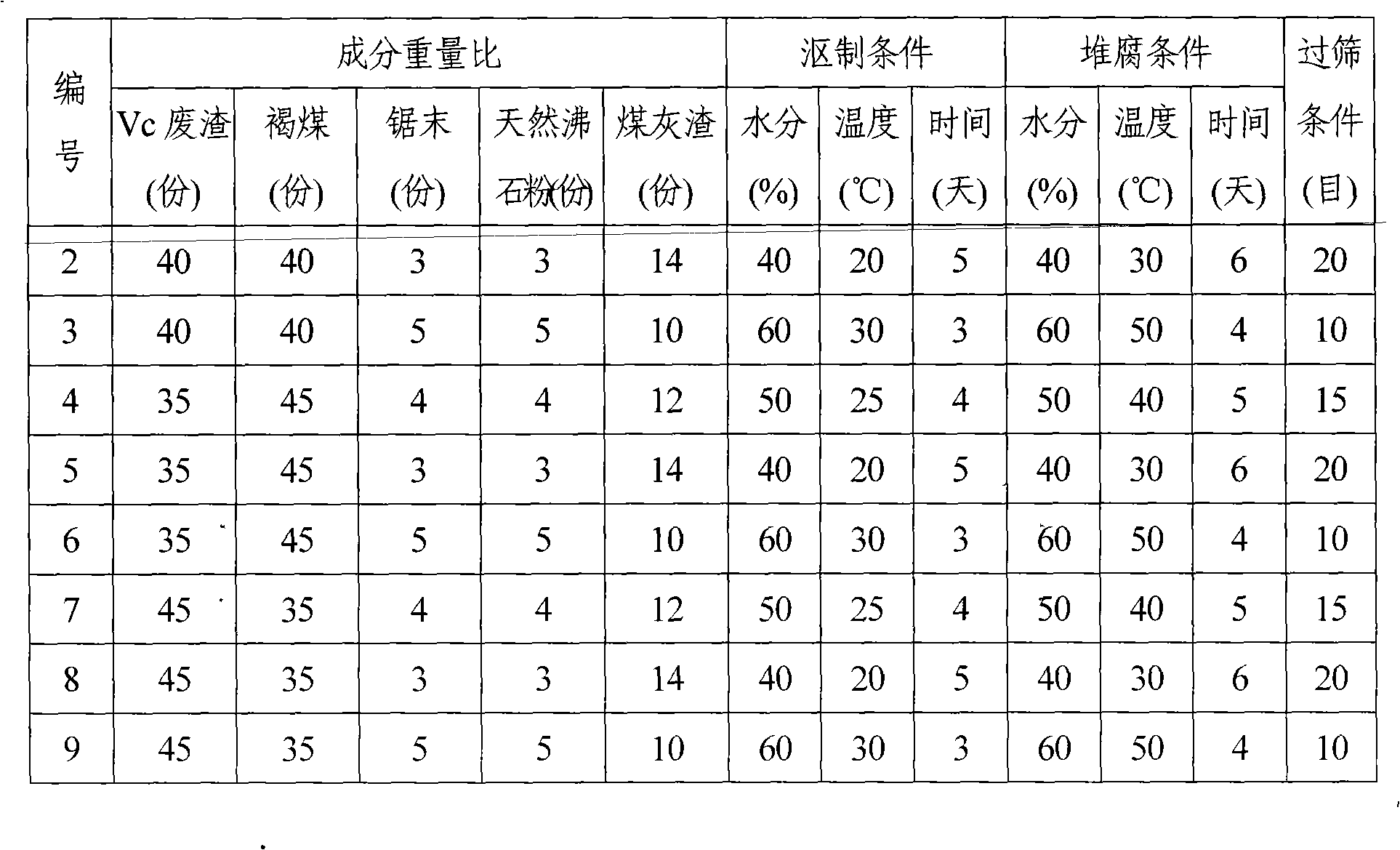

[0037] The difference from Example 1 is: the proportioning of raw materials and the implementation conditions are different (Table 1), and the preparation method is the same as in Example 1.

[0038] Table 1

[0039]

[0040] In the above table, the sieving conditions refer to the conditions of air-drying to a moisture content of 15-20% after composting, mechanical crushing, and sieving. Among them, Examples 2-5 were air-dried to a water content of 18%, and Examples 6-9 were air-dried to a water content of 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com