New process for producing compound fertilizer by municipal sludge

A technology of municipal sludge and compound fertilizer, applied in the direction of sewage/sludge fertilizer, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of high production cost of compound fertilizer and unusable urban sludge, and achieve The effect of meeting agricultural needs, low production costs, and abundant sludge resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: 100 parts by weight of sludge, sludge components: organic matter 30-40%, total nitrogen 2-3.5%, total phosphorus 8-12%, total potassium 2.5-4%, inorganic matter 40.5-57.5%. 1-15 parts of additives, 4.5-8 parts of nitrogen, 0-12 parts of phosphorus, 2-11.5 parts of potassium, and 0-0.5 parts of trace elements.

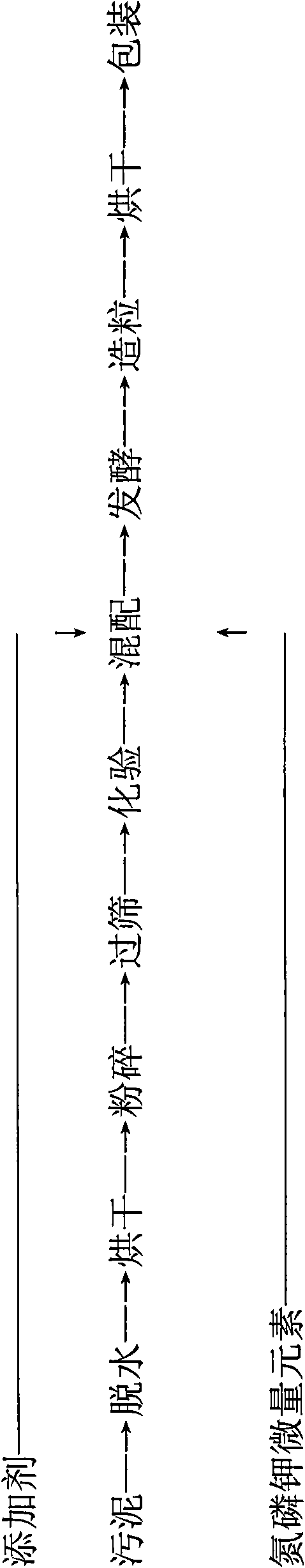

[0015] The technological process is shown in Figure 1, including sludge, dehydration, drying, crushing, sieving, testing, additives, trace elements of nitrogen, phosphorus and potassium, mixing, fermentation, granulation, drying, and packaging.

[0016] Process description:

[0017] 1. Sludge: use domestic sewage treatment sludge from urban sewage treatment plants;

[0018] 2. Dehydration: dehydration by vacuum filtration or centrifugal separation;

[0019] 3. Drying: use a hot air drying furnace to dry, and the drying temperature is 200-450°C;

[0020] 4. Crushing: using a pulverizer;

[0021] 5. Sieving: pass through a 70-120 mesh sieve;

[0022...

Embodiment 2

[0030] 100 parts by weight of embodiment 2 sludge, its composition organic matter (dry basis) 35%, total nitrogen 2.2%, total phosphorus 11%, total potassium 3.6%, inorganic matter 47.6%, additive uses 2 parts of citric acid, if use 50% 8 parts of sulfuric acid, 5.8 parts of total nitrogen is equivalent to 10.5 parts of ammonium sulfate; 1 part of total phosphorus is equivalent to 4.06 parts of diammonium hydrogen phosphate; 4.4 parts of total potassium is equivalent to 3.51 parts of potassium sulfate.

[0031] The process flow and process description are the same as Example 1

[0032] The composition of the compound fertilizer: 8% of total nitrogen, 12% of total phosphorus, 8% of total potassium, and 30% of organic matter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com