Method for treating wastewater containing ammonia, vanadium, chrome and sodium sulfate

A technology for wastewater treatment and sodium sulfate, which is used in neutralization water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

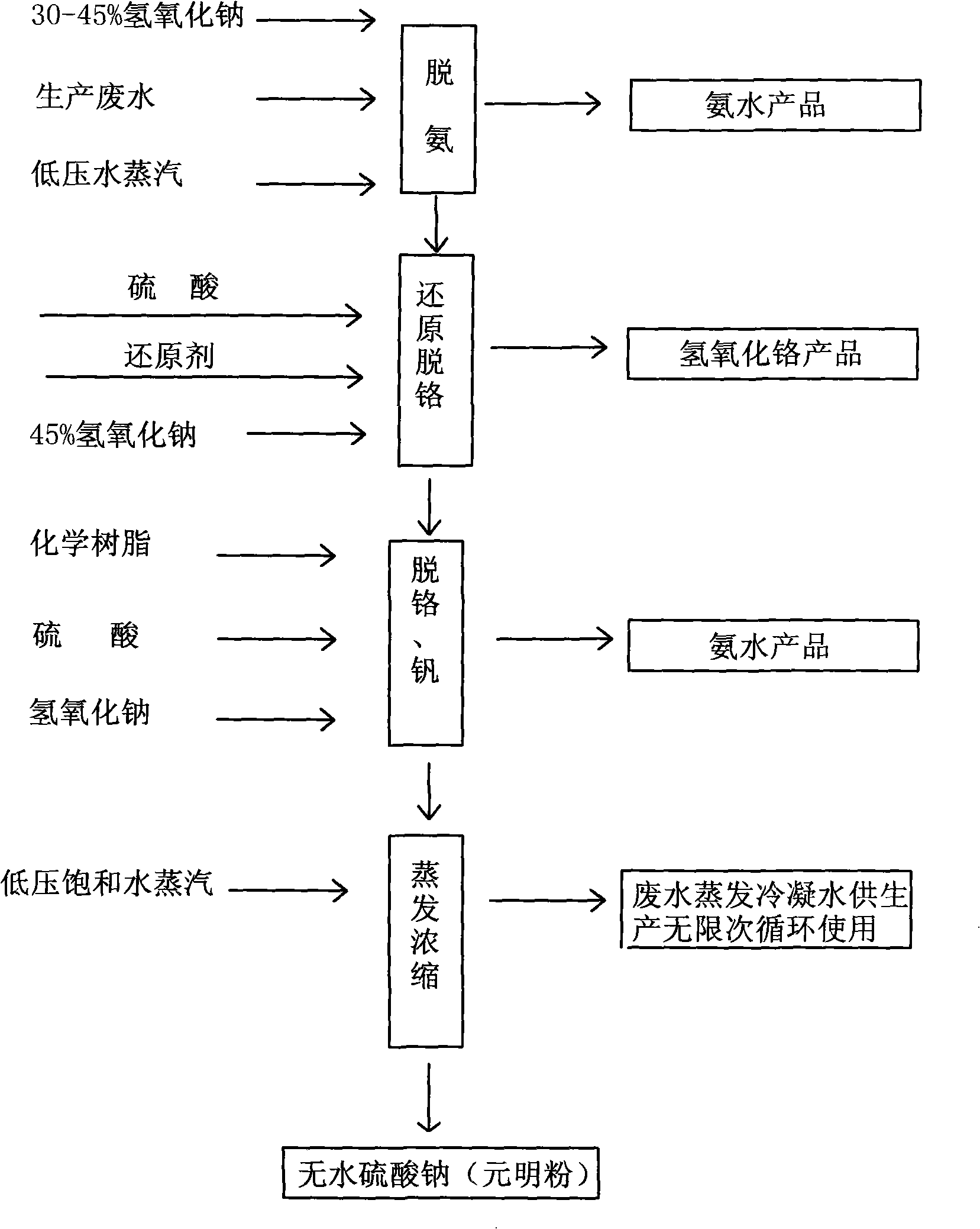

Image

Examples

Embodiment 1

[0012] 1. Ammonia production process by deamination: Mix the production wastewater containing ammonia, vanadium, chromium and sodium sulfate with 40% sodium hydroxide solution in a pipeline mixer, enter the special deamination tower, and control the temperature at the top of the tower at 100°C Next, the alkali-added waste water flows from the top of the tower to the bottom of the tower through multi-stage tray feeding, and the generated ammonia gas escapes from the outlet of the pipe on the top of the tower, and is cooled by the surface condenser to form ammonia water product with the condensed water vapor. The wastewater discharged at the bottom is deammonization wastewater.

[0013] 2. Extract chromium hydroxide. The deamination wastewater is input into an anti-corrosion reaction kettle with heat preservation, the pH of the wastewater is adjusted to 3 with sulfuric acid, and the temperature is maintained at 65°C with steam. According to Cr 6+ Concentration Add an appropriat...

Embodiment 2

[0017] 1. Deamination to produce ammonia water. Alkali is added to the waste water in the form of 40% sodium hydroxide solution by mass percentage, and the temperature at the top of the tower is controlled at 120°C to obtain ammonia water and deamination waste water. Add sulfuric acid to the deamination wastewater to adjust the pH value to 4, keep it warm at 68°C, and use sodium sulfite as a reducing agent to make Cr 6+ reduced to Cr 3+ Chromium hydroxide is generated, and dechrome wastewater is generated at the same time.

[0018] 2. Extract chromium hydroxide. Trace amounts of vanadium and chromium in dechrome wastewater are adsorbed alternately by gel-type anion exchange resin columns (201×7) for high-valence vanadium and chromium ions in wastewater, and then adsorbed by monoaminophosphoric acid-type chelating resin D412. When 201×7 resin After the column is adsorbed and saturated, it is regenerated with sodium hydroxide alkali solution. After the D412 resin column is sa...

Embodiment 3

[0021] 1. Deamination to produce ammonia water. Mix the production waste water containing ammonia, vanadium, chromium and sodium sulfate with 40% sodium hydroxide solution in a pipeline mixer, enter the deamination tower, and control the temperature at the top of the tower to 109°C.

[0022] 2. Extract chromium hydroxide. The deamination wastewater is input into an anti-corrosion reaction kettle with heat preservation, the pH value of the wastewater is adjusted to 5 with sulfuric acid, the temperature is maintained at 70°C with steam, and formaldehyde is used as a reducing agent to make Cr 6+ reduced to Cr 3+ , when Cr 6+ When the concentration is less than 0.03g / 1, then add sodium hydroxide to adjust the wastewater pH to 8, Cr 3+ Chromium hydroxide is generated, separated by filtration, the solid phase is chromium hydroxide product, and the liquid phase is waste water after chromium precipitation.

[0023] 3. Use resin column to adsorb vanadium and chromium. There is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com