Technique for purifying and producing industrial phosphoric acid by wet-process phosphoric acid

A wet-process phosphoric acid and industrial phosphoric acid technology, which is applied in the direction of phosphorus compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of increasing equipment investment and inability to effectively remove anions, and achieve energy saving, good adaptability, and good separation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

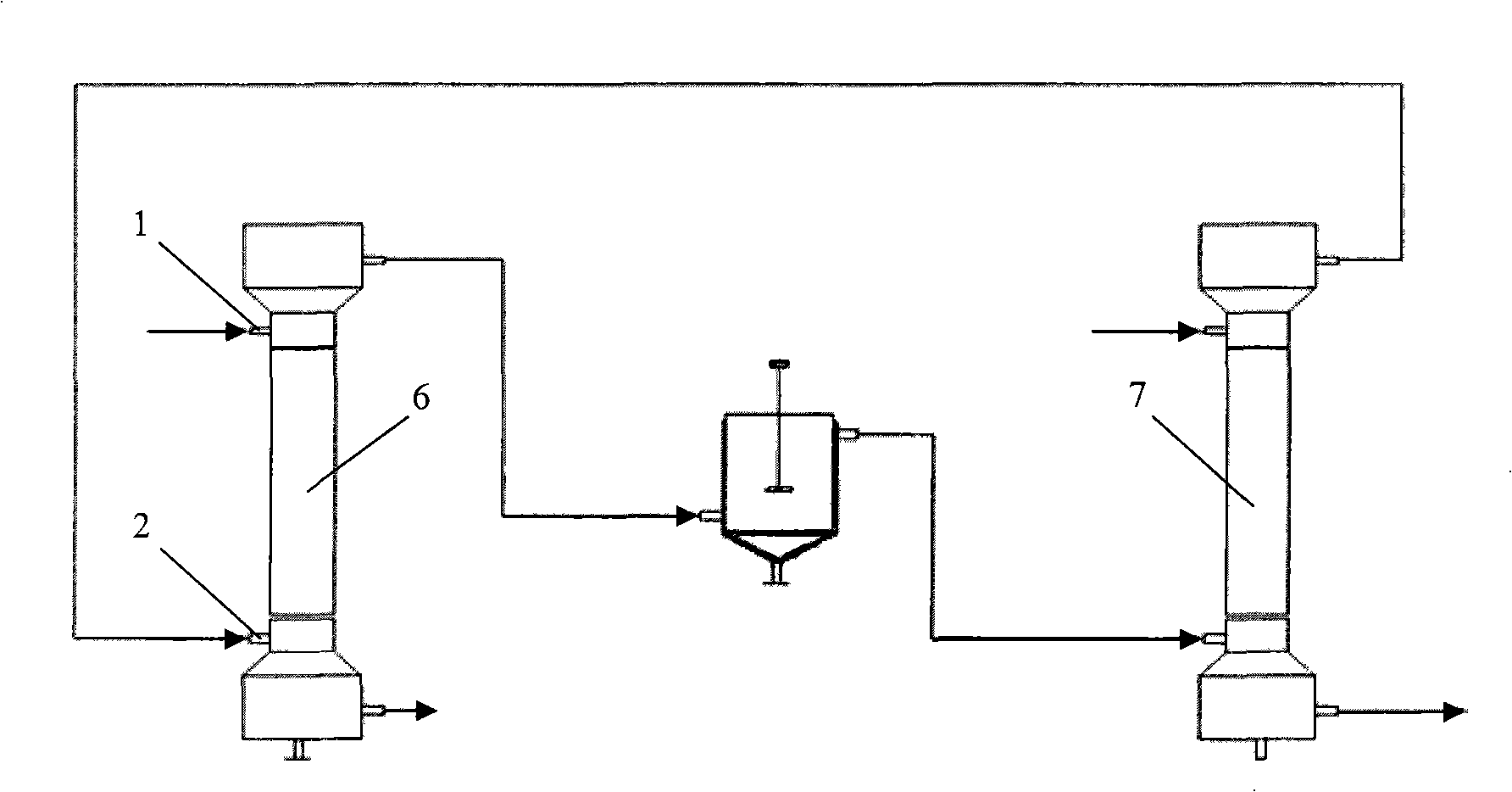

[0031] Embodiment 1: Preparation of industrial phosphoric acid by wet-process phosphoric acid

[0032] In the present embodiment, the composition of wet-process phosphoric acid is as follows (wt%):

[0033]

[0034] 1. Desulfurization and defluorination treatment

[0035] The desulfurization and defluorination treatment is carried out in the desulfurization and defluorination settling tank, and the wet-process phosphoric acid produced by the sulfuric acid method has a content of 25.68% (H 3 PO 4 , wt%), no need to concentrate, add calcium carbonate and phosphate rock powder composite desulfurization reagent according to 120% of the stoichiometric ratio of sulfate ions, wherein the mass ratio of calcium carbonate and phosphate rock powder is 6:1; Sodium carbonate is added to 100% of the stoichiometric ratio, and active silicon additives are added at the same time, and the amount of active silicon added is 0.15% of the fluoride ion stoichiometric ratio. Reaction temperatur...

Embodiment 2

[0050] Embodiment 2: Preparation of industrial phosphoric acid by wet-process phosphoric acid

[0051] In the above process steps, except for the desulfurization and defluorination treatment process, the other processes are the same as in Example 1.

[0052] The desulfurization and defluorination treatment is carried out in the desulfurization and defluorination settling tank, and the wet-process phosphoric acid produced by the sulfuric acid method has a content of 25.68% (H 3 PO 4 , wt%), no need to concentrate, add calcium oxide and phosphate rock powder composite desulfurization reagent according to 150% of the stoichiometric ratio of sulfate ions, wherein the mass ratio of calcium oxide and phosphate rock powder is 7:1; Sodium carbonate is added to 110% of the stoichiometric ratio, and aluminum hydroxide additive is added simultaneously, and the aluminum hydroxide addition is 0.10% of the fluoride ion stoichiometric ratio. Reaction temperature, 45°C, stirring speed, 200r...

Embodiment 3

[0055] Embodiment 3: wet-process phosphoric acid prepares industrial phosphoric acid

[0056] In the above process steps, except for the extraction process, all the other processes are the same as in Example 1.

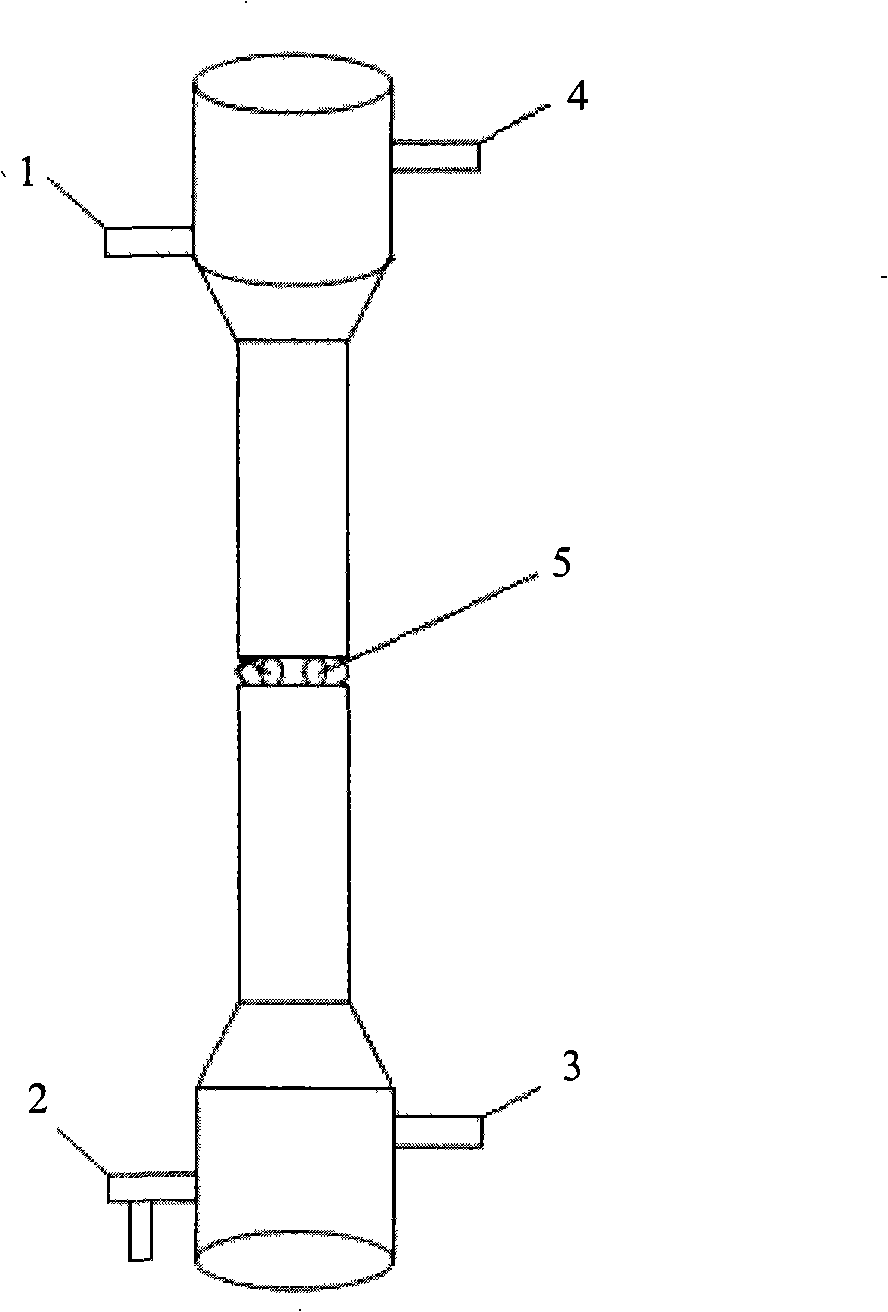

[0057] The extraction is carried out in a pulse vibrating sieve plate column, and the alcohol-ester mixed organic solvent is used for countercurrent extraction. The alcohol-ester volume ratio in the mixed organic solvent is 8:2, wherein the alcohol is isoamyl alcohol, and the ester is tributyl phosphate. Ratio is organic phase: water phase=3: 1, adds extraction promotor (sulfuric acid, mass concentration is 75%) at organic phase entrance, and add-on is 0.5wt% of the wet-process phosphoric acid quality described in step 1), and extraction temperature is 60°C, pulse vibration frequency 35.

[0058] The industrial-grade phosphoric acid that present embodiment gains forms the following table (wt%):

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com