Multilayer sintering and welding process for rectifier bridge

A welding process and rectifier bridge technology, applied in the field of sintering process of rectifier bridge, can solve the problems of low utilization rate of equipment, hinder heat transfer, slowness, etc., and achieve the effects of product quality assurance, air quality improvement, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

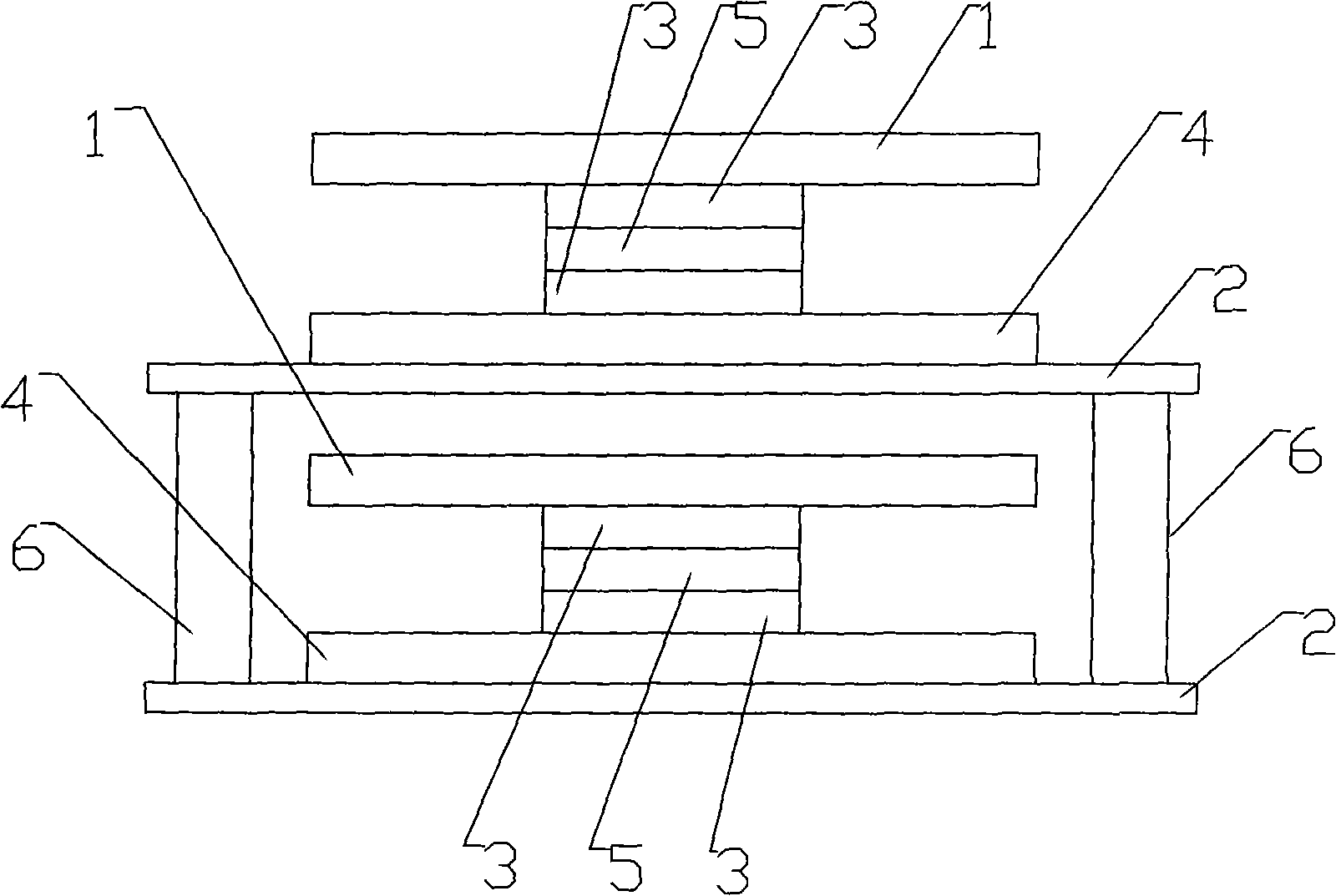

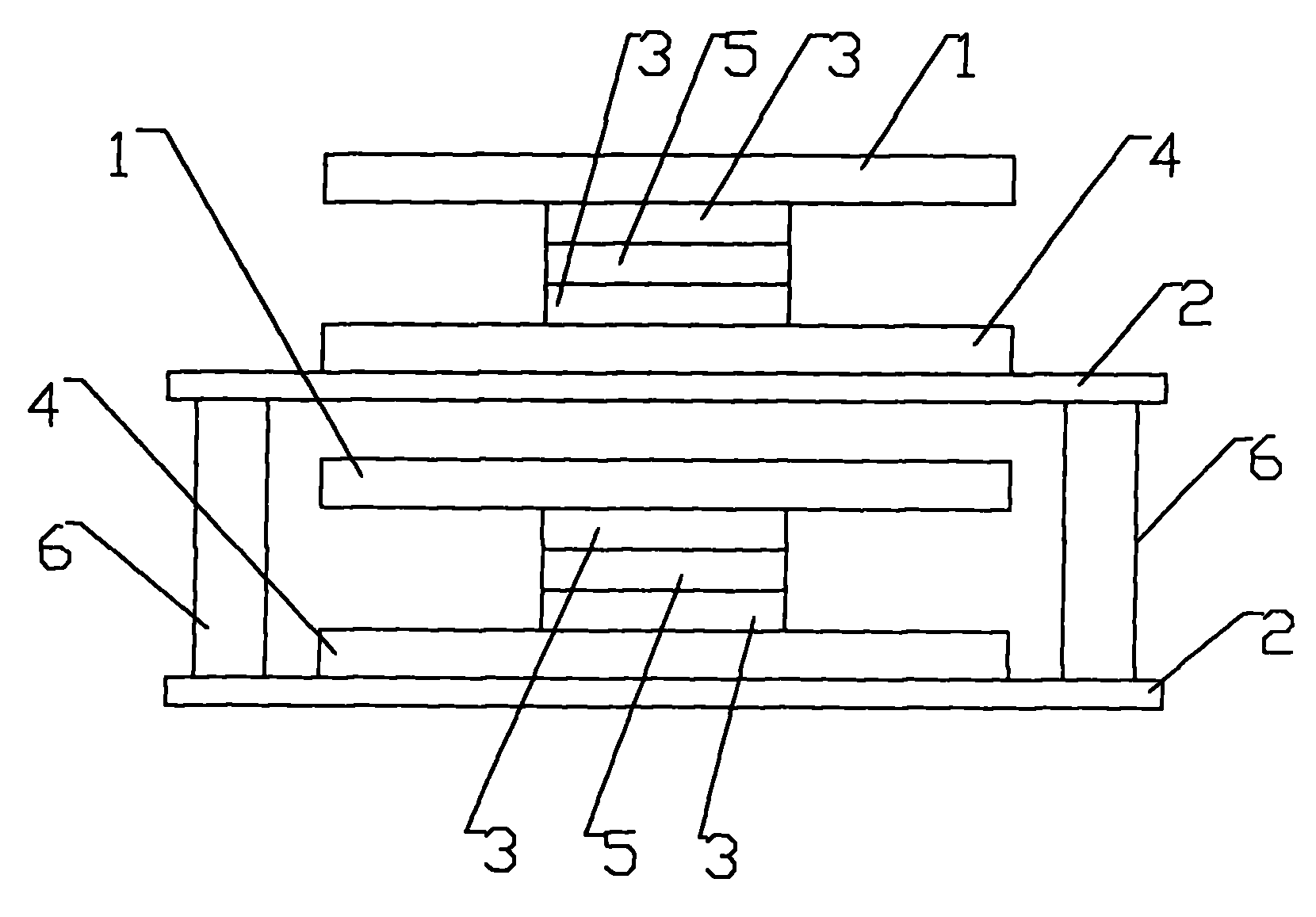

[0037] A rectifier bridge multi-layer sintering and welding process, comprising the following process steps:

[0038] a. Install the connection piece 1 into the graphite lower mold 2 of the mold, brush the solder paste 3 evenly on the bumps of the connection piece 1 and the frame 4 with a glue brushing tool, and then use a vacuum suction pen to absorb the corresponding chip 5 On the bumps of the connecting piece 1, finally place the frame 4 with the solder paste 3 on the connecting piece 1 that has absorbed the chip 5 to form a semi-finished product to be sintered, cover with a flat graphite upper mold, and hold the upper and lower graphite molds tightly , turn it over 180° and put it on the platform to complete the turning operation;

[0039] b. Take off the graphite lower mold 2 and place it on the platform, and horizontally transfer the semi-finished product to be sintered from the graphite upper mold to the removed graphite lower mold 2;

[0040] c. Repeat steps a and b w...

Embodiment 2

[0054] A rectifier bridge multi-layer sintering and welding process, comprising the following process steps:

[0055] a. Install the connecting piece into the graphite lower mold of the mold, brush the solder paste evenly on the bumps of the connecting piece and the frame with the glue brushing tool, and then use the vacuum suction pen to absorb the corresponding chip on the bump of the connecting piece , and finally place the frame that has been brushed with solder paste on the connecting piece that has absorbed the chip to form a semi-finished product to be sintered, cover the flat graphite upper mold, hold the upper and lower graphite molds tightly, turn it over 180° and place it on the platform to complete the flip Operation;

[0056] b. Remove the graphite lower mold and place it on the platform, and horizontally transfer the semi-finished product to be sintered from the graphite upper mold to the removed graphite lower mold;

[0057] c. Repeat steps a and b with the sam...

Embodiment 3

[0067] A rectifier bridge multi-layer sintering and welding process, comprising the following process steps:

[0068] a. Install the connecting piece into the graphite lower mold of the mold, brush the solder paste evenly on the bumps of the connecting piece and the frame with the glue brushing tool, and then use the vacuum suction pen to absorb the corresponding chip on the bump of the connecting piece , and finally place the frame that has been brushed with solder paste on the connecting piece that has absorbed the chip to form a semi-finished product to be sintered, cover the flat graphite upper mold, hold the upper and lower graphite molds tightly, turn it over 180° and place it on the platform to complete the flip Operation;

[0069] b. Remove the graphite lower mold and place it on the platform, and horizontally transfer the semi-finished product to be sintered from the graphite upper mold to the removed graphite lower mold;

[0070] c. Repeat step a and step b with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com