Ball end repairing cutter

A tool and ball head technology, used in the field of cutting tools and metal cutting tools, can solve the problems that the electrode ball head is difficult to meet the surface roughness requirements, the work efficiency is low, and the labor intensity of workers is high, and it is easy to ensure the surface processing quality. Improve welding Quality, convenient surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

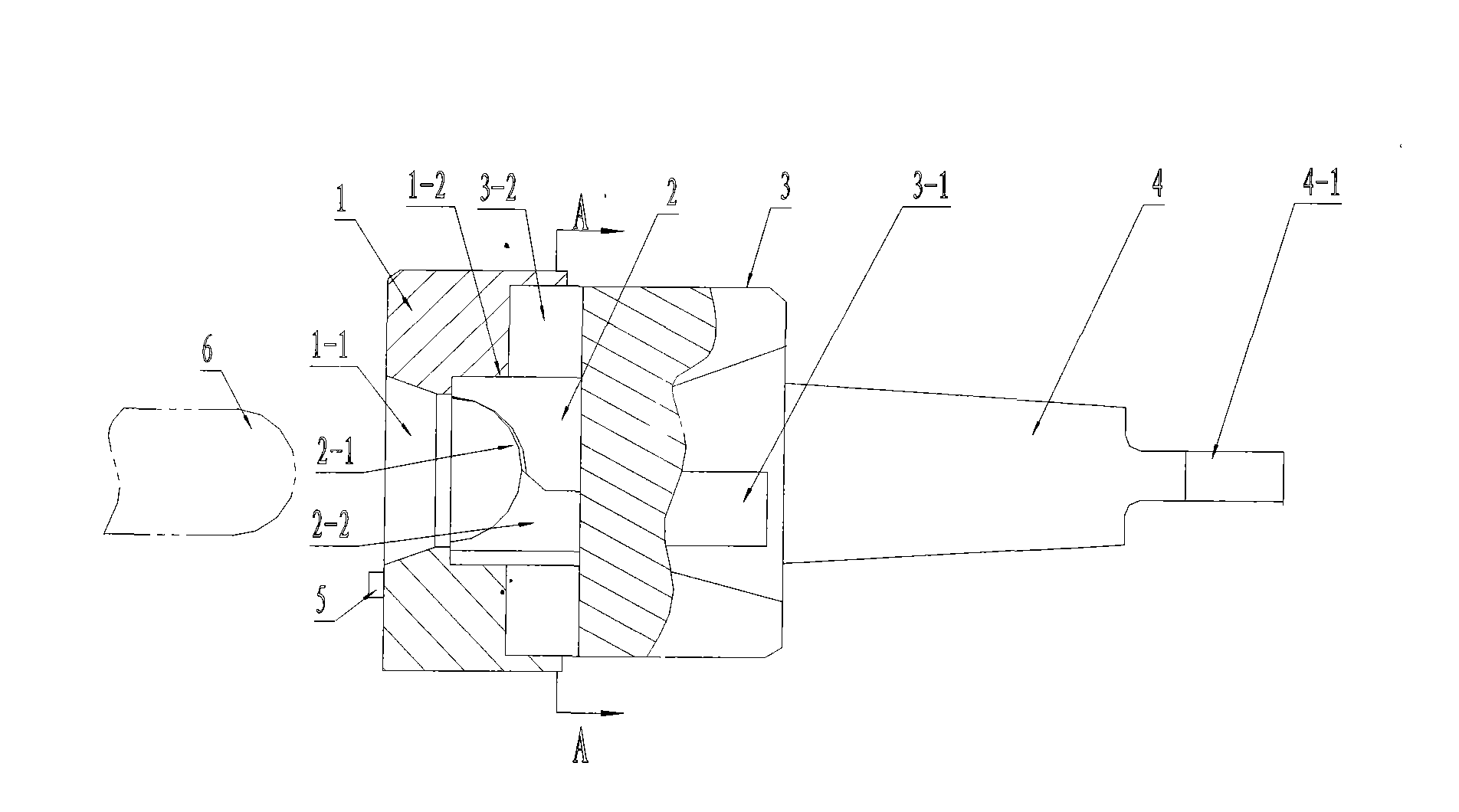

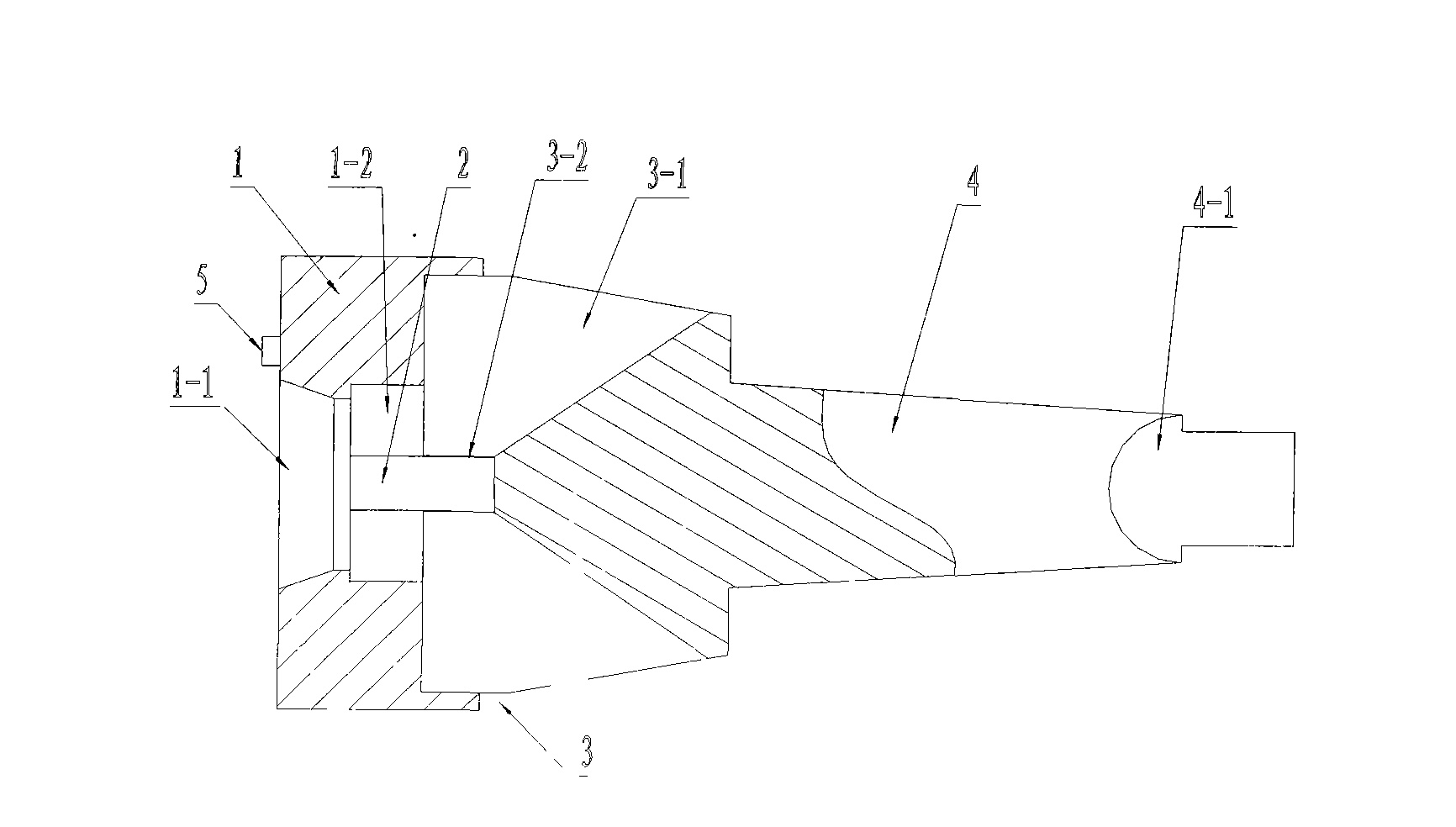

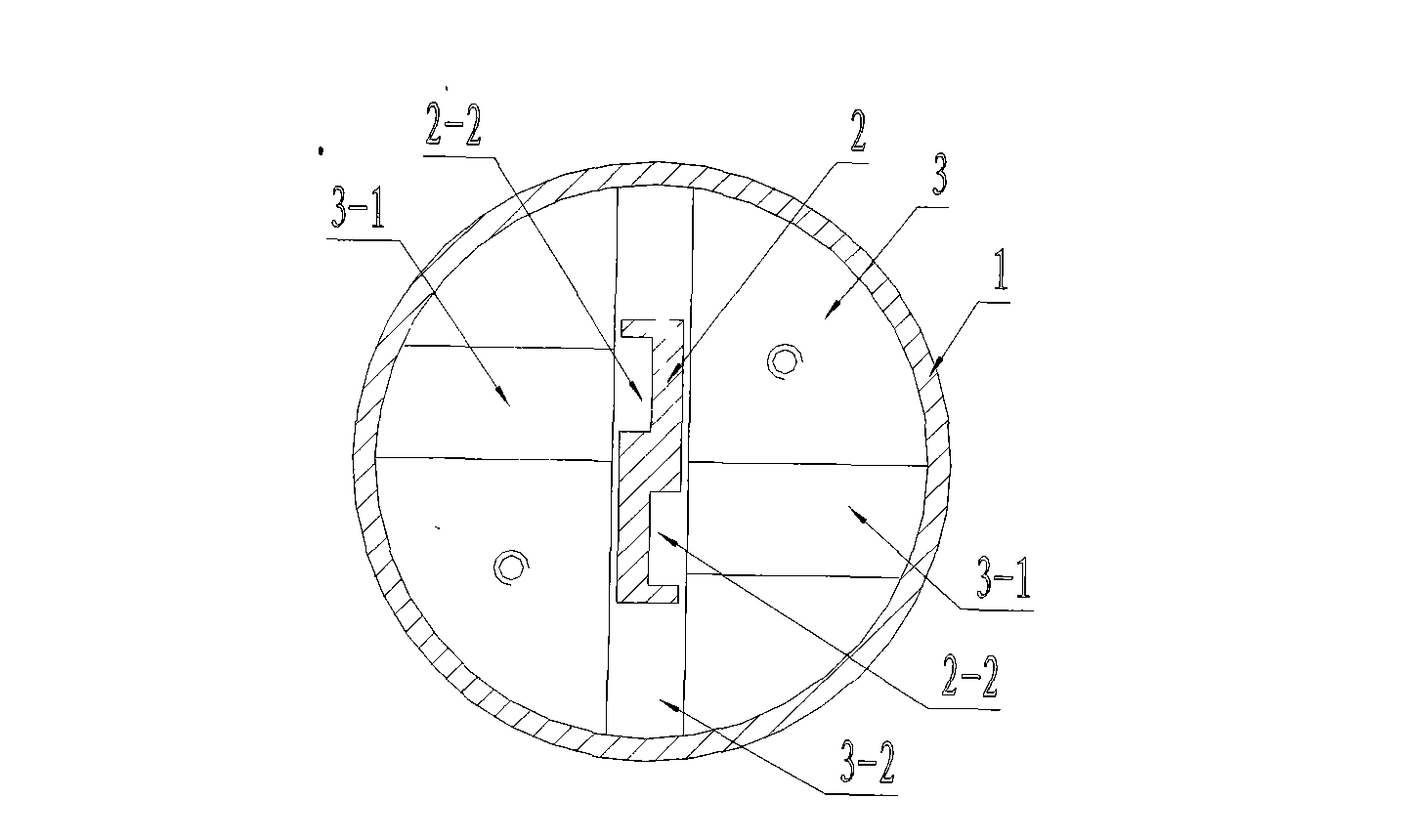

[0016] see Figure 1-3 , the present invention comprises a cutter body 3, a handle 4 and a blade 2 fixed on the cutter body, the cutter body is cylindrical, the axis of the cutter body coincides with the center line of the blade installed thereon, and the blade is provided with an arc blade 2-1 and the chip removal groove 2-2, the arc blade is located at the front end of the blade, and the arc of the blade matches the arc of the processed electrode ball head 6, and the chip removal groove is connected to the blade. A chip removal channel 3-1 is arranged axially on the cutter body, and the chip removal groove communicates with the chip removal channel. The front end of the cutter body is radially provided with a blade mounting groove 3-2, and the rear end of the cutter body is located in the groove. The knife handle 4 is located at the rear of the knife body, and its end is provided with a clamping table 4-1.

[0017] still refer to Figure 1-3 , the cutter body 3 front port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com