External preparation for skin and cleansing agent for skin

A technology for external skin preparations and skin cleansers, applied in the fields of external skin preparations and skin cleansers, can solve problems such as enhanced cosmetic irritation, skin astringency, redness, etc., and achieves good fusion, easy to rinse off, and stability. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

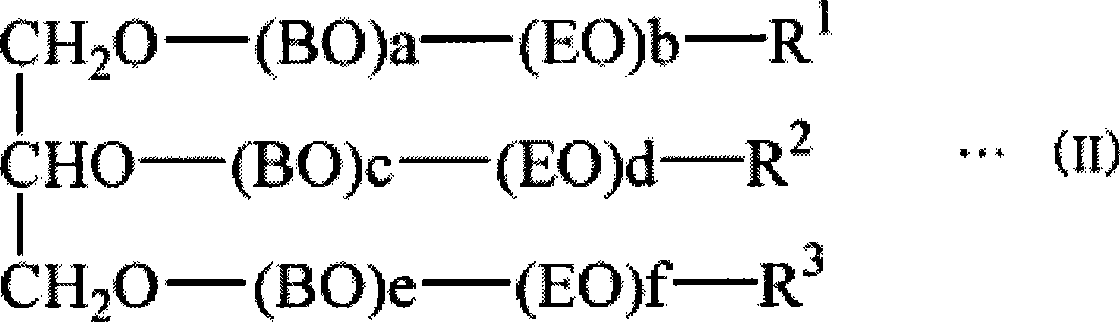

Method used

Image

Examples

Embodiment 1

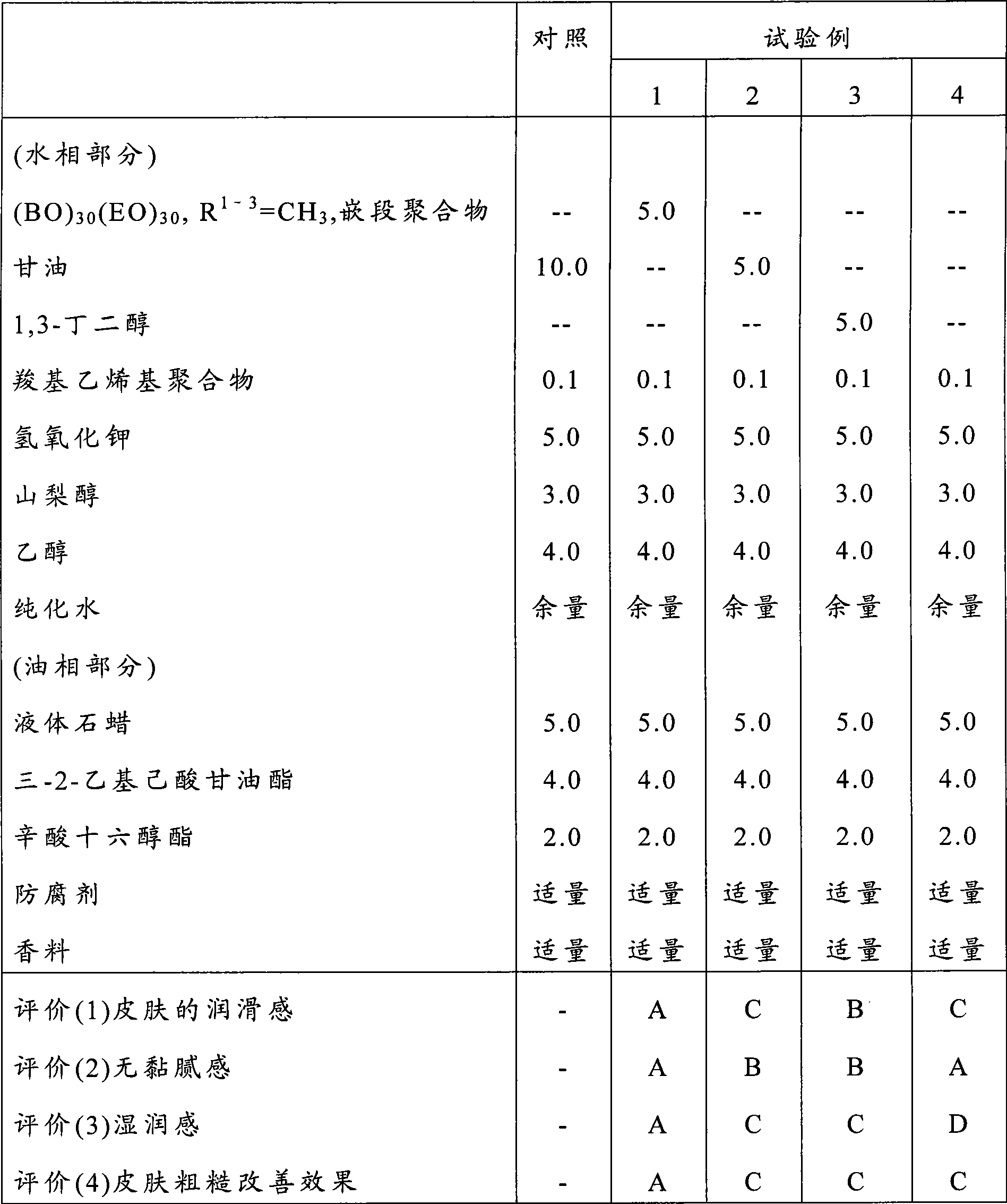

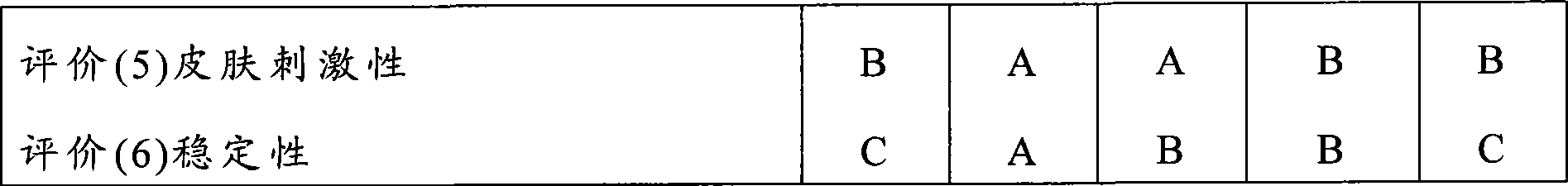

[0105] First, evaluation tests for usability and stability of the external preparation for skin of the present invention were performed.

[0106] First, the evaluation method of the external preparation for skin used in this test will be described. The application site of the skin external preparation is the cheek.

[0107] In addition, the composition of the conventional skin external preparation used as a control is as follows:

[0108] (water phase part)

[0109] (1) Glycerin 10.0% by mass

[0110](2) Carboxy vinyl polymer 0.1

[0111] (3) Potassium hydroxide 5.0

[0112] (4) Sorbitol 3.0

[0113] (5) Ethanol 4.0

[0114] (6) Purified water balance

[0115] (oil phase part)

[0116] (7) Liquid paraffin 5.0

[0117] (8) Glyceryl tri-2-ethylhexanoate 4.0

[0118] (9) Cetyl octanoate 2.0

[0119] (10) Appropriate amount of preservatives

[0120] (11) Appropriate amount of spices

[0121] (Evaluation 1): Skin lubricating feeling

[0122] With regard to the lubrica...

Synthetic example 1

[0223] Synthesis of Polyoxybutylene (30mol) Polyoxyethylene (30mol) Trimethylglyceryl Ether (Block Type Oxyalkylene Derivative)

[0224] 92 g of glycerin and 18 g of potassium hydroxide as a catalyst were put into the autoclave, and after replacing the air in the autoclave with dry nitrogen, the catalyst was completely dissolved at 140° C. while stirring. Next, 2160 g of butylene oxide was dripped with a dripping device, and stirred for 2 hours. Then, 1320 g of ethylene oxide was dripped with a dripping apparatus, and it stirred for 2 hours. Then add 400g of potassium hydroxide, replace the inside of the system with dry nitrogen, press-in 300g of methyl chloride at a temperature of 80-130°C, and react for 5 hours. Thereafter, the reaction composition was discharged from the autoclave, neutralized with hydrochloric acid, adjusted to pH 6 to 7, and treated at 100° C. under reduced pressure -0.088 MPa (gauge pressure) for 1 hour to remove contained water. In addition, in order ...

Synthetic example 2

[0227] Synthesis of Polyoxyethylene (57mol) Trimethylglyceryl Ether (Oxyalkylene Derivative)

[0228] 92 g of glycerin and 18 g of potassium hydroxide as a catalyst were put into the autoclave, and after replacing the air in the autoclave with dry nitrogen, the catalyst was completely dissolved at 140° C. while stirring. Next, 2508 g of ethylene oxide was dripped with a dripping device, and stirred for 2 hours. Then add 400g of potassium hydroxide, replace the inside of the system with dry nitrogen, press-in 300g of methyl chloride at a temperature of 80-130°C, and react for 5 hours. Thereafter, the reaction composition was discharged from the autoclave, neutralized with hydrochloric acid, adjusted to pH 6 to 7, and treated at 100° C. under reduced pressure -0.088 MPa (gauge pressure) for 1 hour to remove contained water. In addition, in order to remove the salt generated after the treatment, filtration was performed to obtain an alkylene oxide derivative.

[0229] The hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com