Method and device for liquid density measurement

A liquid density and measuring device technology, which is applied to determine the specific gravity and other directions by measuring the pressure difference, can solve the problems of difficult to meet the needs, low accuracy and efficiency, and achieve the effect of strong practicability, simple implementation and reliable measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

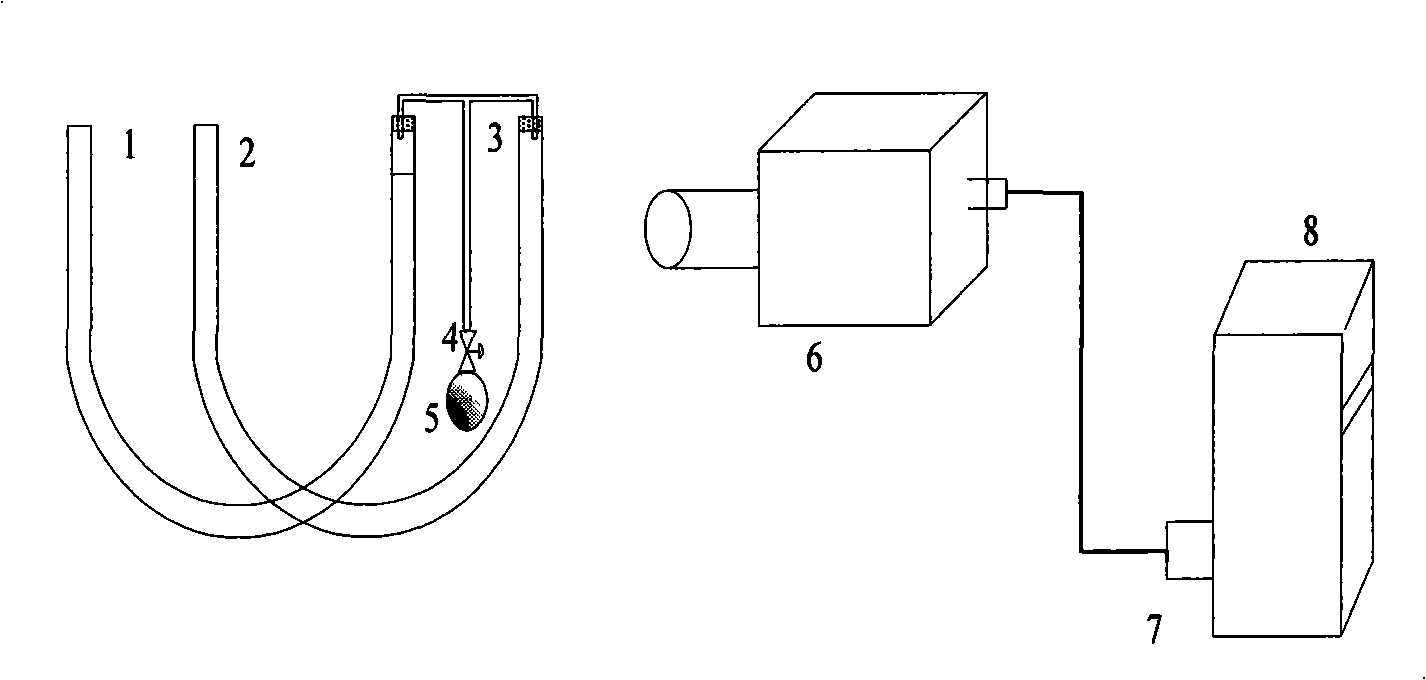

[0017] Device of the present invention and realization principle are:

[0018] Such as figure 1 As shown, the left port of the first U-shaped pipe 1 and the second U-shaped pipe 2 are connected to the atmosphere, and the right port is connected by a three-way pipe 3 after adding a rubber stopper. A scale mark is engraved on the first U-shaped tube 1 as the standard liquid level. The first U-shaped pipe 1 and the second U-shaped pipe 2 are placed side by side. The other end of the tee pipe 3 is connected to the rubber ball 5 through the control valve 4 . The camera 6 adopts a camera, and the camera is aimed at the right end of the first U-shaped pipe 1 and the second U-shaped pipe 2, and the computer 8 is connected with the camera by an image acquisition card 7.

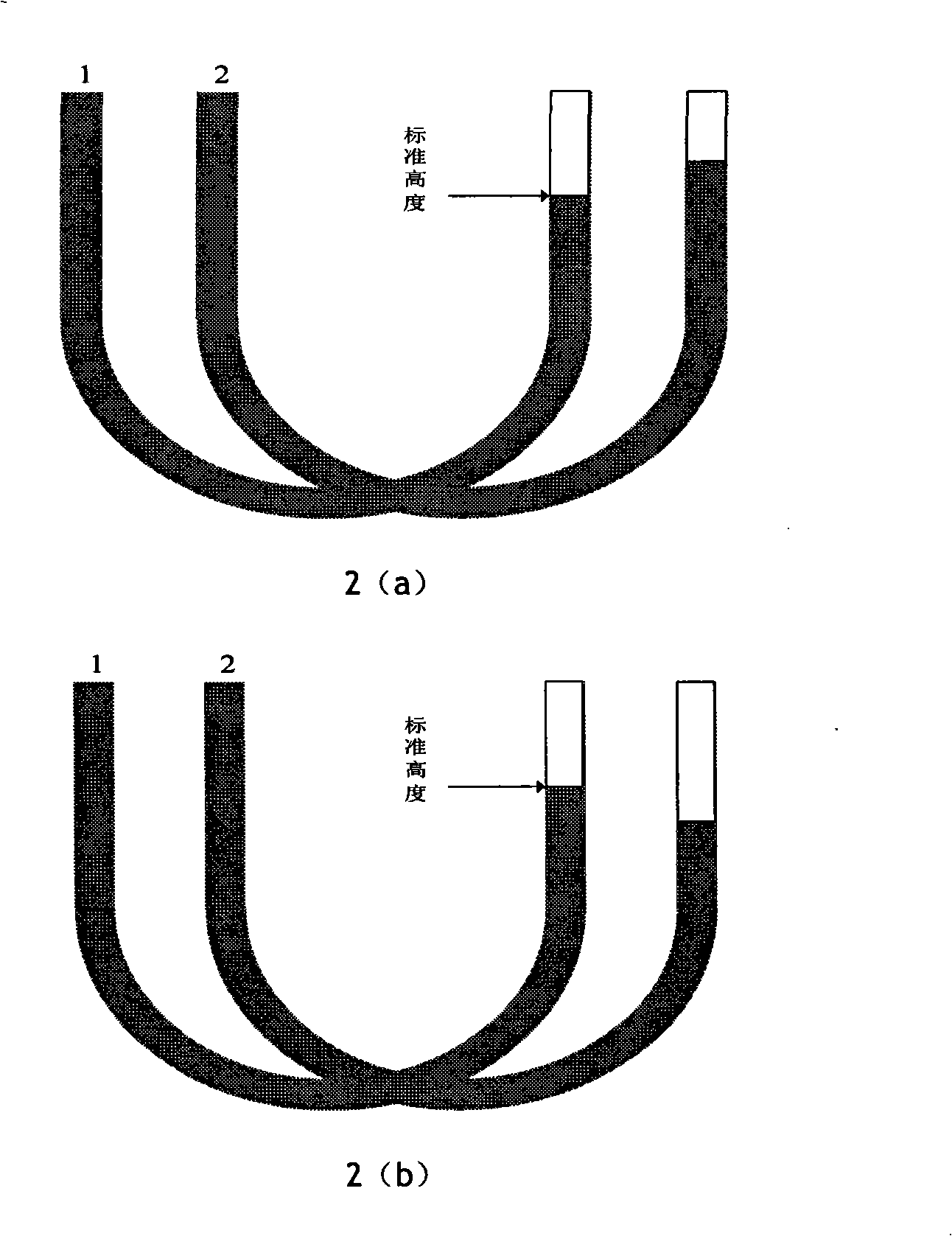

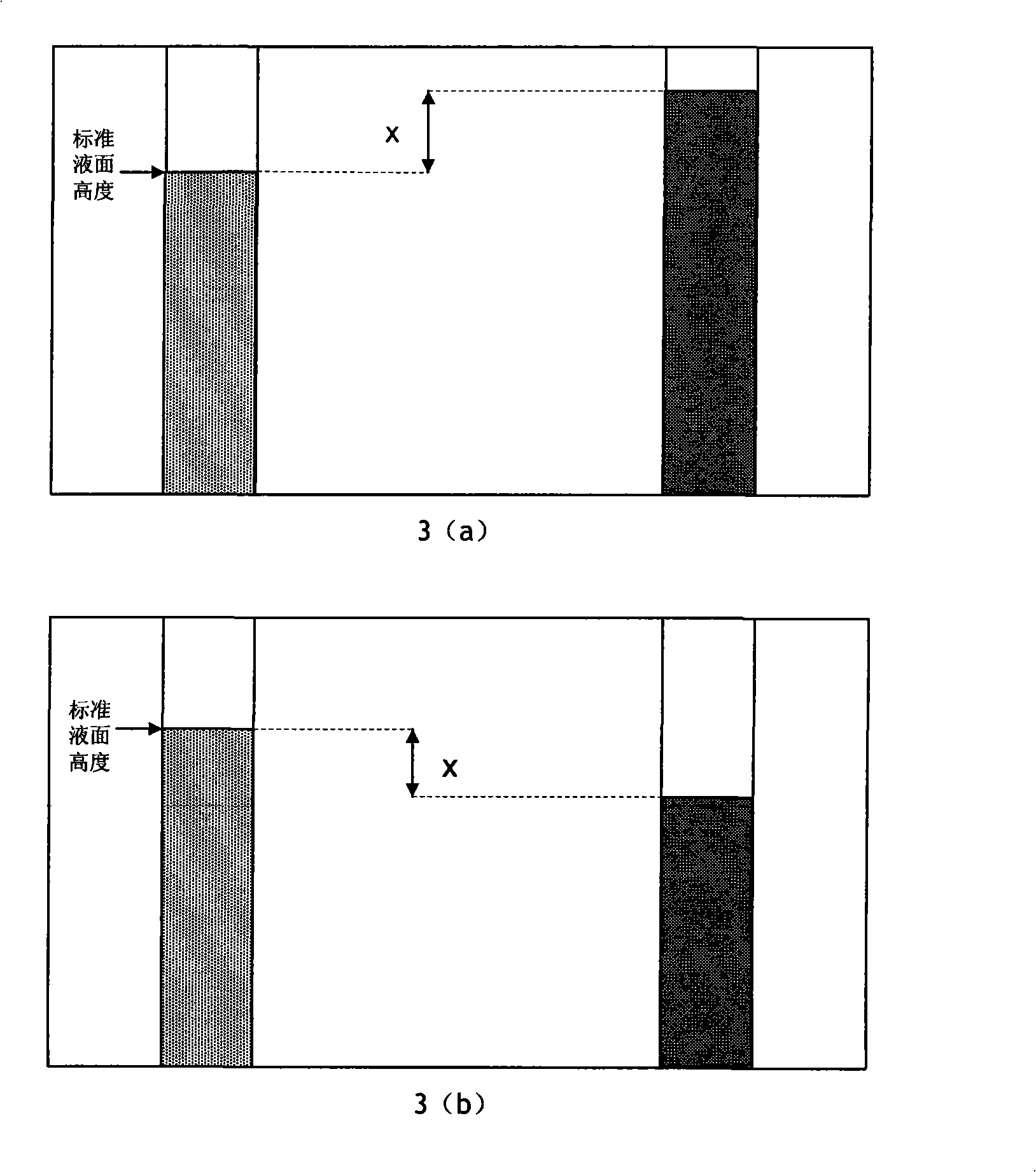

[0019] During work, the first U-shaped tube 1 is filled with the liquid to be tested, and the second U-shaped tube 2 is filled with the standard liquid (such as water). When air is filled into the first U-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com