Ignition device for vacuum refining furnace

A vacuum refining furnace and conduit technology, applied in the direction of combustion ignition, combustion method, ignition by electric spark, etc., can solve problems such as easy loosening of joints, achieve simplified installation process, ingenious structure, and improve product qualification rate and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

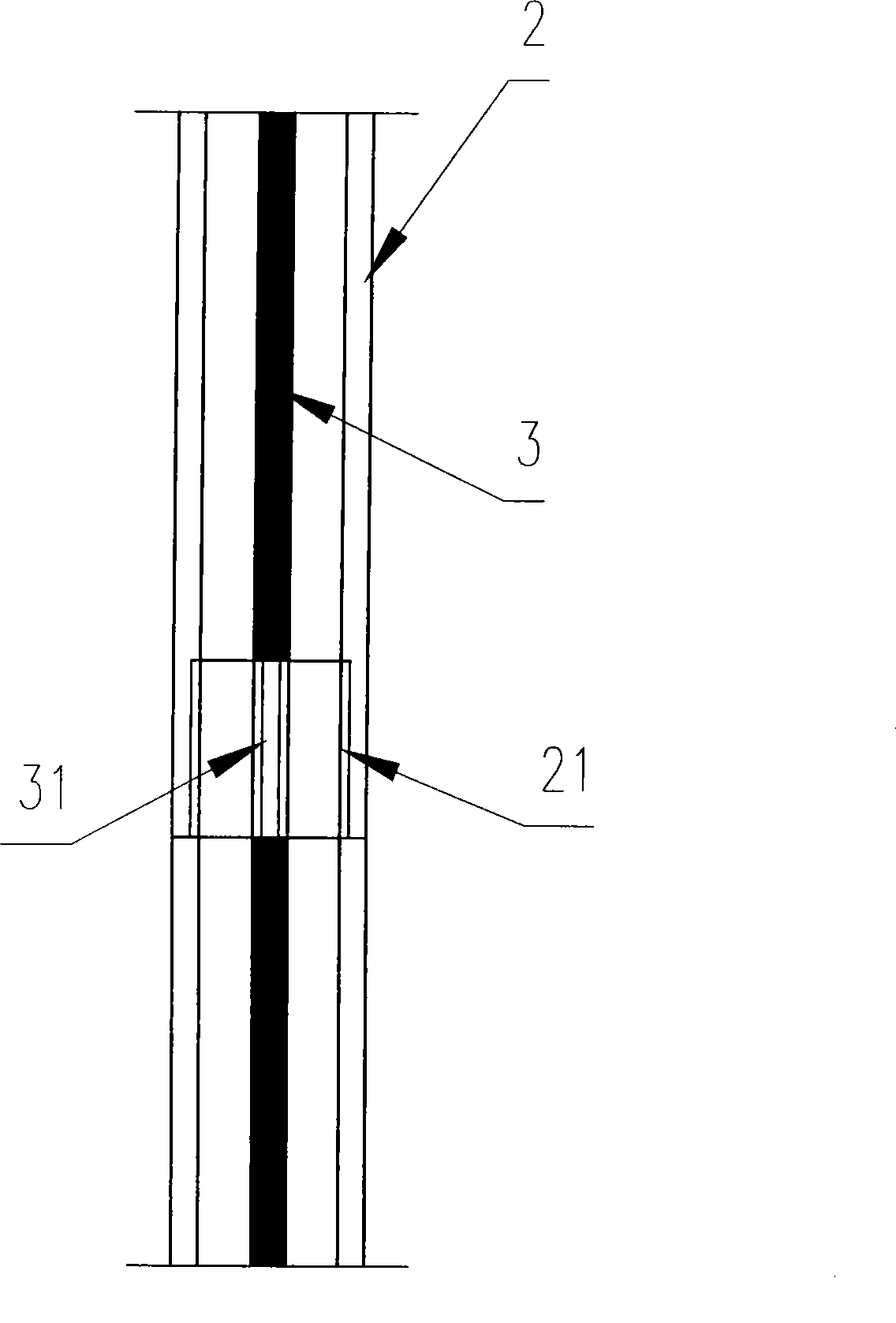

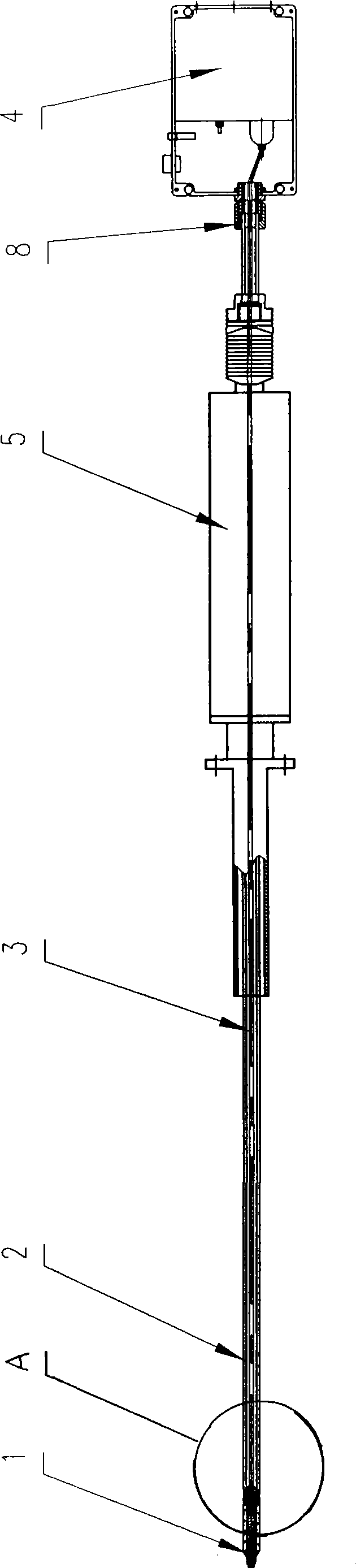

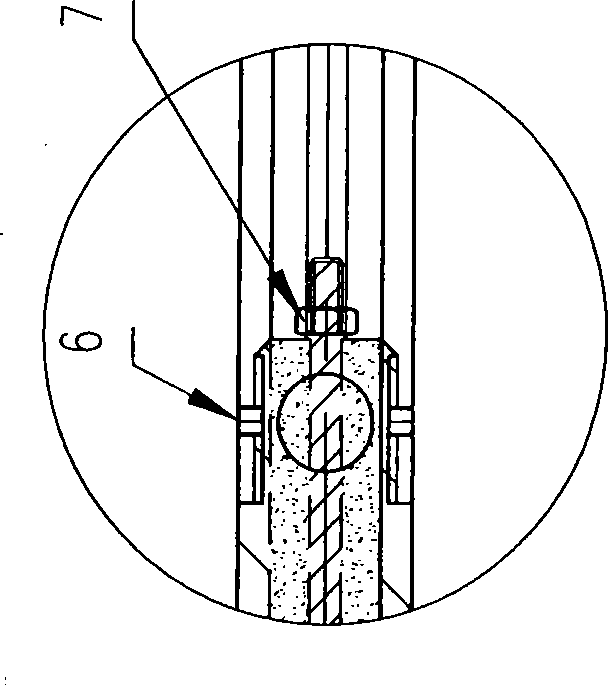

[0013] from figure 2 , image 3 It can be seen from the figure that an ignition device for a vacuum refining furnace is composed of an ignition head 1, a conduit 2, a high-voltage ignition cable 3, an ignition transformer 4, and a lifting cylinder 5. The conduit 2 is an integral seamless steel pipe, and its straightness is guaranteed after measures such as straightening and centerless grinding. The external thread of one end of the ignition head 1 is spirally connected with the internal thread of one end of the conduit 2, and one side of the external thread of the ignition head 1 extending into the conduit 2 is reinforced with a set screw 6, and the high-voltage ignition cable 3 is connected with the ignition The end of head 1 with external thread is fixedly connected by nut 7; after conduit 2 passes through lifting cylinder 5, its other end is screwed on ignition transformer 4, and then reinforced with set screw 8; one end of high-voltage ignition cable 3 is connected to le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com